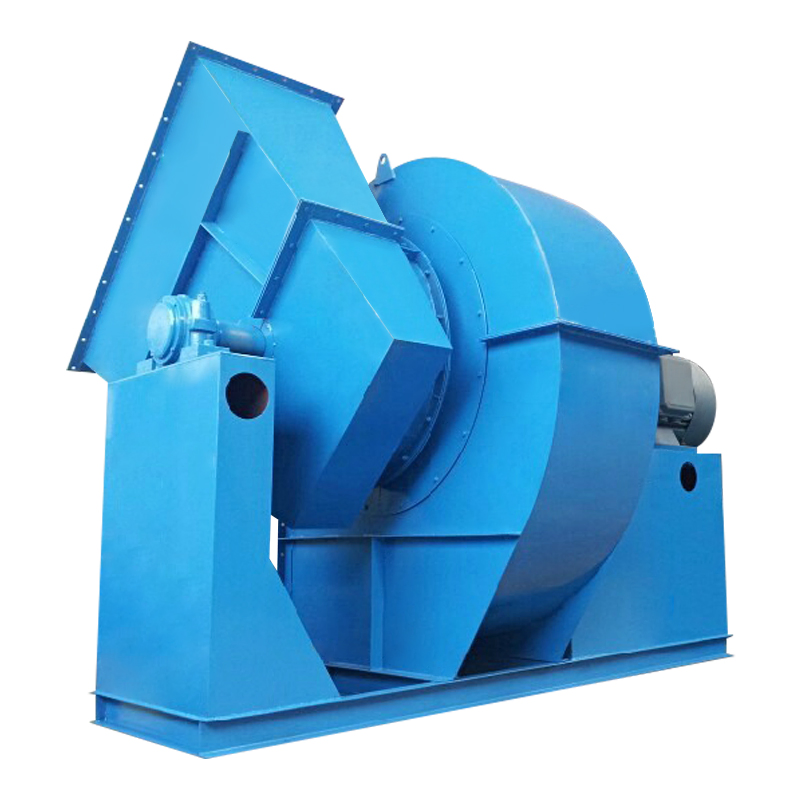

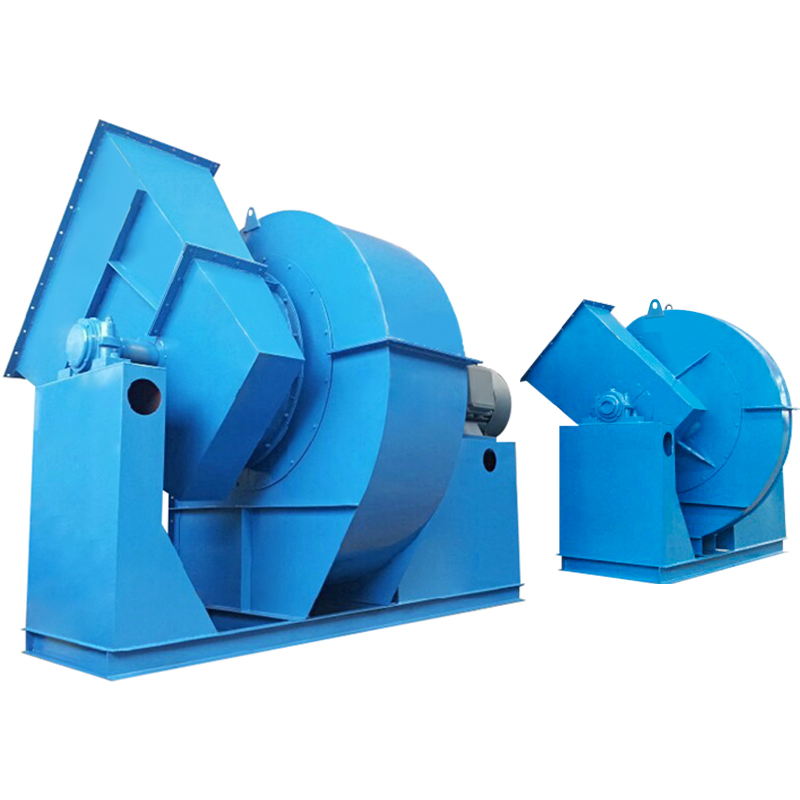

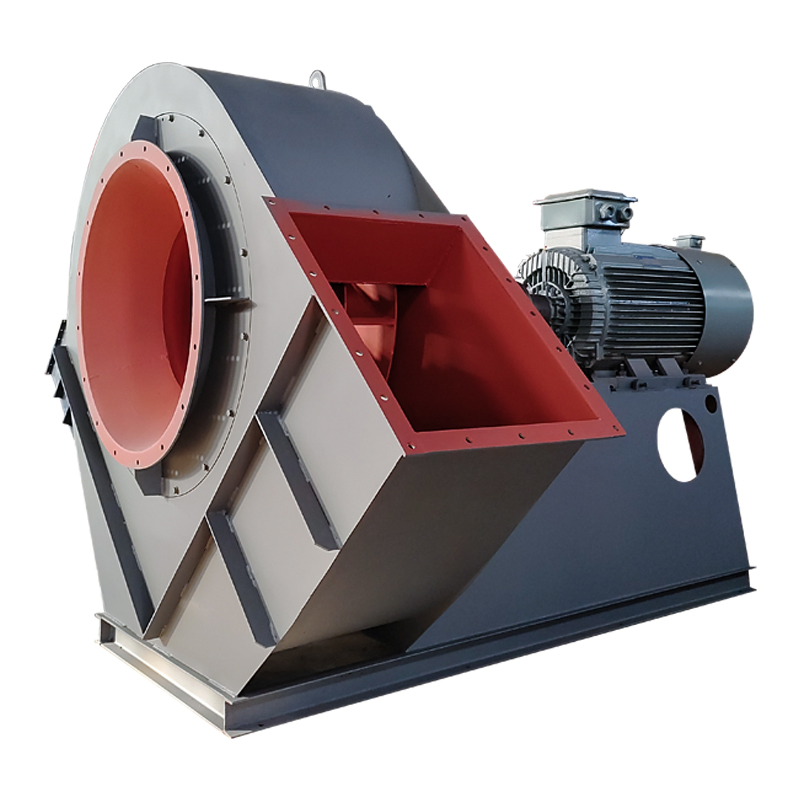

The XH-HSF-17/19 Backward/Forward Curved Centrifugal Fan is engineered for demanding industrial applications including forging furnaces and high pressure forced ventilation systems. This robust fan excels in material conveying applications for air and non-corrosive gases.

With a maximum operating temperature of 80°C (standard 50°C), this fan handles media containing dust and hard particles up to 150mg/m³. For specialized applications involving flammable, explosive, or corrosive gases, or temperatures exceeding 80°C, custom design solutions are available.

The fan features precision-engineered stainless steel blades mounted on an aluminum frame, ensuring durability and efficient airflow. Multiple speed options and motor configurations allow for optimal performance across various industrial scenarios.

Key applications include boiler systems, workshop ventilation, mining operations, textile factories, oil field installations, chemical processing plants, kiln operations, metallurgical processes, power generation facilities, and cement production plants.

All units undergo rigorous quality testing including dynamic balancing before shipment to ensure reliable operation and long service life. The fan's design emphasizes energy efficiency while maintaining robust construction for industrial environments.

Great experience overall with the delivery and handling of this industrial blower unit. The logistics were handled exceptionally well; the shipment arrived precisely within the estimated timeframe provided at the time of order. All components were securely packaged, with no signs of damage or mishandling during transit, which is crucial for such heavy-duty equipment. The quality of the fan itself appears robust and well-manufactured, aligning with the descriptions and expectations for industrial-grade machinery. Initial inspections show solid construction and finish. Regarding service, the support team was responsive and professional in coordinating the delivery details and providing necessary documentation. They were prompt in answering pre-delivery inquiries, which made the process smooth. Generally, a satisfactory procurement process from start to finish, focusing on the essential aspects of receiving the product.

I am thoroughly impressed with the delivery speed of this product; it arrived much faster than I anticipated, which was a pleasant surprise. The quality of the fan is exceptional, with a sturdy build that feels durable and reliable for industrial use. The customer service team was very responsive and helpful, addressing my queries promptly and professionally. Overall, I'm very satisfied with this purchase and would recommend it to others based on these aspects.

Outstanding experience from start to finish! The delivery was incredibly fast, arriving two days earlier than the estimated date, which was a pleasant surprise. Packaging was robust and secure, ensuring the product was well-protected during transit. Quality-wise, the fan appears to be built with high-grade materials, and the finish is smooth without any visible defects. Customer service was exceptional; the support team responded promptly to my inquiries and provided clear, helpful guidance. Overall, a very satisfying purchase that exceeded my expectations in terms of logistics, quality, and service.

Wow, the shipping was incredibly fast and well-handled. The packaging was secure and professional, ensuring the product arrived in perfect condition. The quality of the fan is outstanding; it feels robust and well-constructed, exactly as described. Customer service was responsive and helpful throughout the process, answering all my questions promptly. Overall, a very positive experience from start to finish.