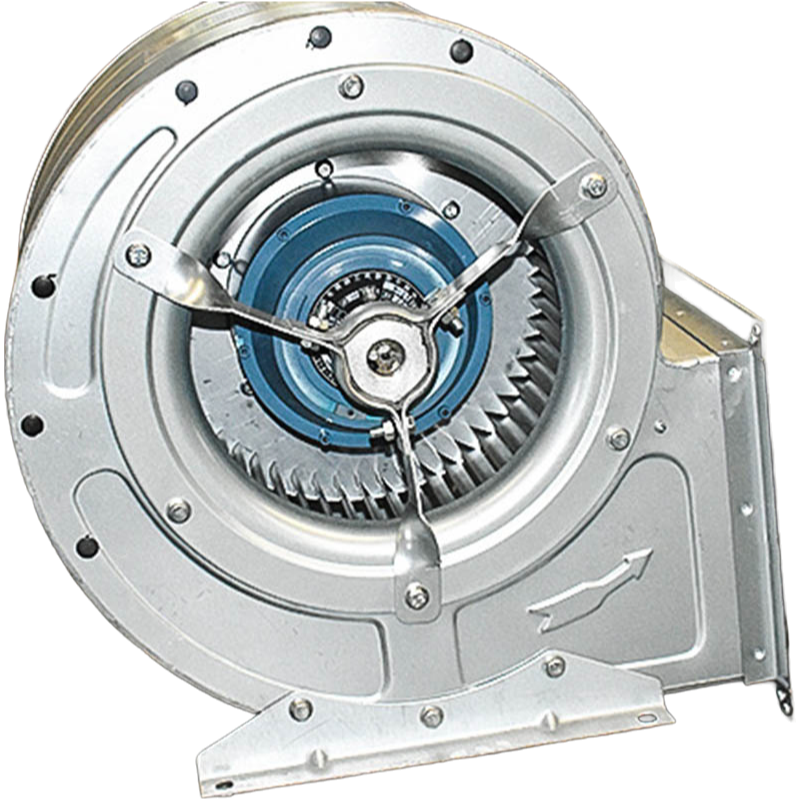

The S4-72-11 centrifugal ventilator represents advanced airflow technology designed for demanding industrial and commercial applications. This radial fan excels in environments requiring reliable air movement against significant resistance.

Centrifugal fans operate on the principle of converting rotational energy into pressure energy, making them particularly effective for systems with substantial airflow resistance. The unique impeller design creates centrifugal force that propels air outward, generating higher static pressure compared to axial fans.

These ventilators are engineered with multiple blade configurations including forward-curved, backward-curved, and radial designs. Each configuration offers distinct advantages for specific pressure and flow requirements. The backward-curved blade design, in particular, provides excellent energy efficiency and reduced noise levels.

The construction materials available include FRP, steel, stainless steel, aluminum, and PP/PVC composites, ensuring compatibility with various environmental conditions. The fan housing and impeller can be customized to handle corrosive gases, high temperatures, and abrasive particles commonly encountered in industrial settings.

Performance characteristics include stable operation under varying load conditions, making these fans ideal for dynamic industrial processes. The design minimizes performance fluctuations when system resistance changes, ensuring consistent airflow delivery.

Installation flexibility is another key advantage, with options for horizontal or vertical mounting and integration into complex duct systems. The three connection types (direct drive, belt drive, and coupling drive) provide additional customization possibilities to meet specific space and performance requirements.

Applications span across multiple industries including HVAC systems for air handling units and furnaces, industrial processes requiring pneumatic conveying and combustion air supply, pollution control systems for fume extraction, and drying/cooling operations in food processing and textile manufacturing.

The fan's design prioritizes maintenance efficiency with accessible components and simplified service procedures. The robust construction ensures long service life even in demanding operating conditions.

Smooth and swift delivery from start to finish; the shipping was handled professionally with timely updates. The build quality is robust and durable, meeting industrial standards without any flaws. Customer service was exceptional, providing prompt and helpful responses to all my inquiries. Overall, a reliable experience that I'd happily recommend for anyone in need of such equipment.

Excellent shipping speed; the product arrived much earlier than expected, which was a pleasant surprise. Every aspect of the packaging was secure, preventing any damage during transit. Efficient communication from the seller made the process smooth and hassle-free. The quality appears robust and durable, meeting my expectations for industrial use. Overall, a very positive experience that I would gladly repeat in the future.