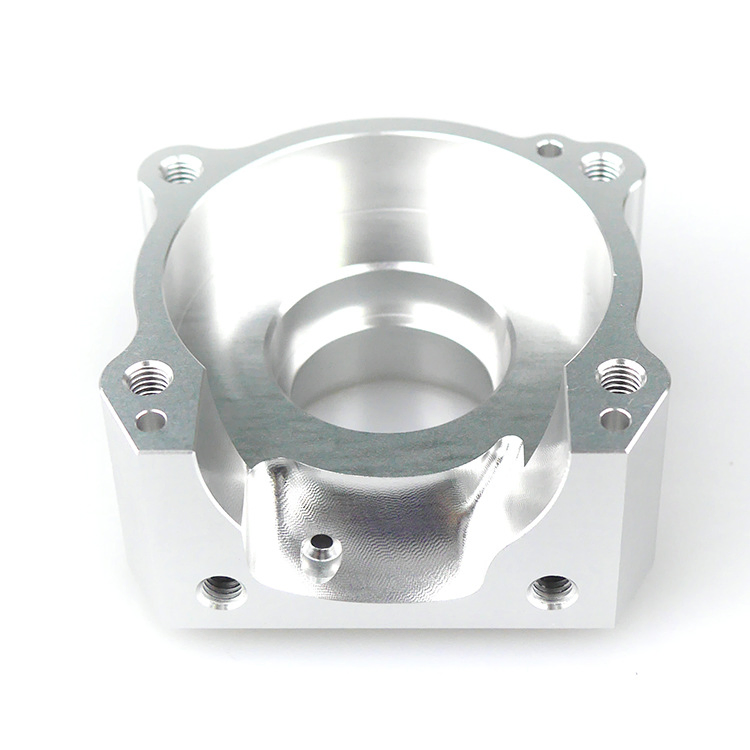

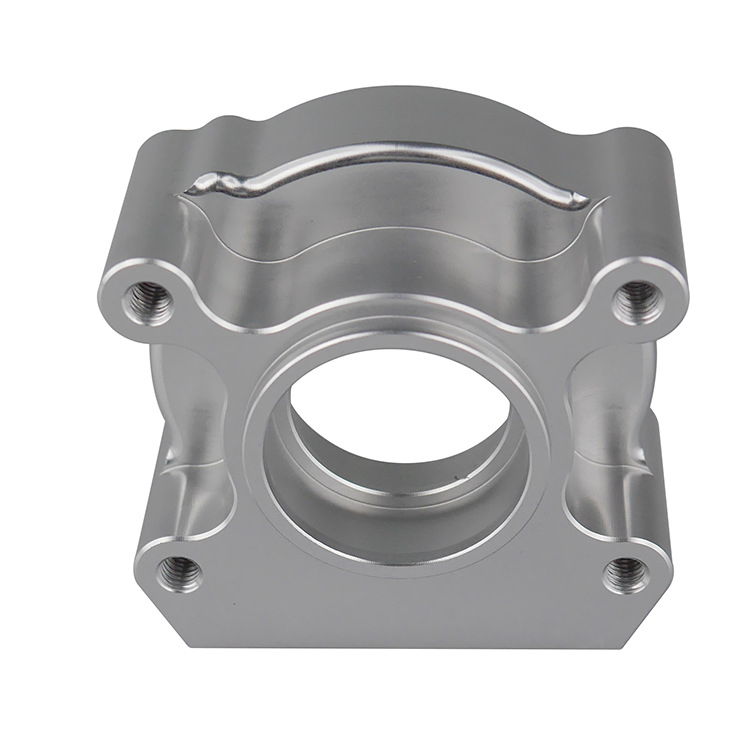

Our CNC machining services provide high precision metal parts for various industrial applications. We specialize in custom OEM production with capabilities including CNC turning, milling, and 5-axis machining.

We work with multiple materials including aluminum alloys (6061-T6, 5052, 7075), stainless steel (303, 304, 316L), brass, copper, and various plastics. Our machining processes can achieve tight tolerances of ±0.01mm and surface roughness down to Ra 0.1.

Available surface treatments include anodizing, sandblasting, powder coating, plating (chrome, nickel, zinc), polishing, and more. We can accommodate various finishing requirements based on your specifications.

Our production capabilities include CNC machining centers, turning centers, grinding machines, and 5-axis mill-turn equipment. We can handle parts up to 2200mm in length with our large-format machines.

For quality assurance, we maintain a complete testing laboratory with CMM, micrometers, optical comparators, and other precision measurement tools. All parts are inspected according to ISO 2768 standards or customer-specific requirements.

We accept various file formats for production including STEP, STP, IGS, X-T, DXF, DWG, and PDF. Our engineering team can work with your existing designs or help develop new solutions.

Typical applications for our CNC machined parts include industrial machinery components, medical device parts, automotive components, aerospace applications, and more. We can produce prototypes, small batches, or large volume production runs.

Our standard lead time is 3-7 days for samples and approximately 30 days for bulk orders, depending on complexity and quantity. We offer flexible packaging options including wooden boxes, cartons, and pallets to ensure safe transportation.

Just received my latest order of custom CNC machined components, and I must say the entire experience was outstanding from start to finish. The logistics were handled with remarkable precision and speed. My shipment arrived ahead of schedule, which was a pleasant surprise given the complexity and custom nature of the parts. The packaging was exceptionally secure, with each individual metal part carefully wrapped and cushioned to prevent any transit damage. The tracking information provided was accurate and updated in real-time, allowing me to monitor the journey of my order with ease. This level of logistical transparency and efficiency is truly commendable and sets a high standard for suppliers in this field. Regarding the quality, the craftsmanship is simply impeccable. The precision milling and turning on the various materials I selected are evident in every detail. The surfaces are smooth, the tolerances are exact as specified, and there is absolutely no sign of burrs or imperfections. The parts fit together perfectly in my assembly, which speaks volumes about the supplier’s attention to detail and commitment to delivering superior quality. It is clear that they utilize advanced machinery and have highly skilled technicians overseeing the production process. The materials provided feel robust and exactly as described, giving me full confidence in the durability and performance of the final product. In terms of service, the communication was consistently professional, responsive, and helpful. Every inquiry I had was addressed promptly and thoroughly, with clear explanations provided at each stage of the order process. The team demonstrated a genuine understanding of my requirements and offered valuable insights when needed. They made the entire custom ordering procedure straightforward and stress-free. Overall, this supplier has proven to be exceptionally reliable, delivering top-tier quality parts through efficient logistics and backed by excellent customer service. I am thoroughly satisfied and will undoubtedly be returning for future machining needs.

Outstanding experience from start to finish. The logistics were handled with remarkable precision; the parts arrived well ahead of the estimated schedule, which was a fantastic surprise. Every component was meticulously packaged, ensuring no damage during transit. The quality of the machined parts is exceptional, meeting all specified tolerances and exhibiting a superb surface finish. The material selection provided was comprehensive, and the final product reflects top-tier craftsmanship. Regarding service, the communication was consistently clear, professional, and responsive. The team was proactive in providing updates and addressed all inquiries promptly. Overall, a highly reliable and proficient supplier that delivers excellent value.

Diligent and dependable service from start to finish. The logistics were handled with impressive efficiency; my order arrived well ahead of the estimated schedule, which was a welcome surprise. Packaging was secure and professional, ensuring all parts were in perfect condition upon arrival. Communication throughout the process was clear and timely, with prompt responses to my initial inquiry. The quality of the machined components is outstanding. They exhibit precise tolerances and a superb finish, exactly as specified in the technical drawings. The supplier demonstrated a clear understanding of the requirements. Overall, a highly satisfactory experience with a supplier that excels in reliable delivery and consistent quality.

Brilliant experience overall. The logistics were handled exceptionally well; my order arrived ahead of schedule, which was a very pleasant surprise. The packaging was secure and professional, ensuring all parts were perfectly intact upon arrival. Regarding quality, the components are precisely manufactured. The finish is smooth, and the tolerances appear to be spot-on, matching the technical drawings provided. The service team was responsive and helpful throughout the process, answering my preliminary questions promptly and providing clear updates. They demonstrated a clear understanding of custom machining requirements. This supplier seems very reliable for precision parts. I am thoroughly satisfied with this transaction and would confidently consider them for future projects requiring CNC turning or milling services.

Smooth and efficient delivery process from start to finish. The logistics were handled impeccably, with clear communication at every stage and the parts arriving exactly on the promised date. Packaging was secure and professional, ensuring everything was in perfect condition upon arrival. Regarding the quality, the machined components exhibit exceptional precision and finish. The materials used feel robust and exactly as specified, with no visible imperfections. The overall craftsmanship is outstanding, meeting very high standards. The service provided was equally commendable. The support team was responsive, knowledgeable, and proactive in addressing preliminary queries. They demonstrated a clear commitment to customer satisfaction, making the entire ordering process straightforward and reliable. A highly satisfactory experience overall, strongly recommended for anyone in need of precision custom parts.

Just received my order of custom CNC parts, and I am thoroughly impressed with the overall experience. The logistics were handled exceptionally well; the shipment arrived ahead of schedule, which was a pleasant surprise. Everything was packaged securely, ensuring that the precision components were protected during transit. The quality of the machined parts is outstanding. They meet the exact specifications I provided, with clean finishes and precise tolerances. The service provided by the team was also top-notch. Communication was clear and prompt throughout the entire process, from the initial quote to the final delivery. Any questions I had were answered quickly and professionally. This supplier clearly prioritizes customer satisfaction and delivers on their promises. I highly recommend them for anyone in need of reliable custom machining services.

Worthwhile experience from start to finish. The logistics were handled with impressive efficiency; my order arrived well ahead of the estimated schedule, which was a fantastic surprise. Packaging was secure and professional, ensuring all parts were perfectly intact upon arrival. Regarding quality, the components exhibit excellent craftsmanship. The finishes are precise, edges are clean, and the tolerances appear to be spot-on based on my initial inspection. The materials used feel robust and exactly as specified in the order. Customer service was equally commendable. The communication was clear, prompt, and helpful throughout the quoting and ordering process. Any questions I had were answered thoroughly and without delay. Overall, a very reliable and professional service for custom machined parts. I am thoroughly satisfied and would not hesitate to place future orders or recommend them to others seeking precision parts.

Fantastic experience overall. The logistics were handled exceptionally well. My order arrived ahead of the estimated schedule, which was a very pleasant surprise. The packaging was secure and professional, ensuring all parts were perfectly protected during transit. Communication regarding shipping updates was clear and timely. Regarding quality, the precision of the machined parts is outstanding. They match the provided specifications exactly, with excellent surface finishes and no visible defects. The materials used feel robust and of high grade. The service provided by the team was equally impressive. They were responsive, patient with my inquiries, and provided helpful guidance throughout the ordering process. Quotations were detailed and transparent, with no hidden costs. The overall professionalism from initial contact to final delivery was remarkable. I felt confident in their capabilities from the start, and the final product confirmed that trust. For anyone needing reliable custom machining with various materials, this supplier is a top-tier choice. The combination of efficient logistics, superior quality, and excellent customer service makes them stand out. I will definitely be returning for future projects and would not hesitate to recommend them to others seeking precision CNC parts.

Beyond impressed with the entire experience. The logistics were handled flawlessly; my order arrived ahead of schedule, which was a fantastic surprise. Every step of the shipping process was clearly communicated, leaving no room for uncertainty. Regarding quality, the precision of the machined parts is simply outstanding. The finish is smooth, and the tolerances appear to be exactly as specified, reflecting a high level of craftsmanship. The service provided was equally commendable. The team was responsive, patient with my inquiries, and demonstrated genuine professionalism throughout our correspondence. They provided clear updates and made the entire custom order process feel seamless and straightforward. It is rare to find a supplier that excels in all three critical areas—logistics, quality, and service—so consistently. This has built a great deal of trust, and I would not hesitate to place future orders or recommend them to colleagues. The combination of reliable delivery, superior product quality, and exceptional customer support makes this supplier a standout choice for custom machining needs. The attention to detail from the initial quote to the final delivery was evident and very much appreciated. Overall, a truly satisfactory and hassle-free experience from start to finish.