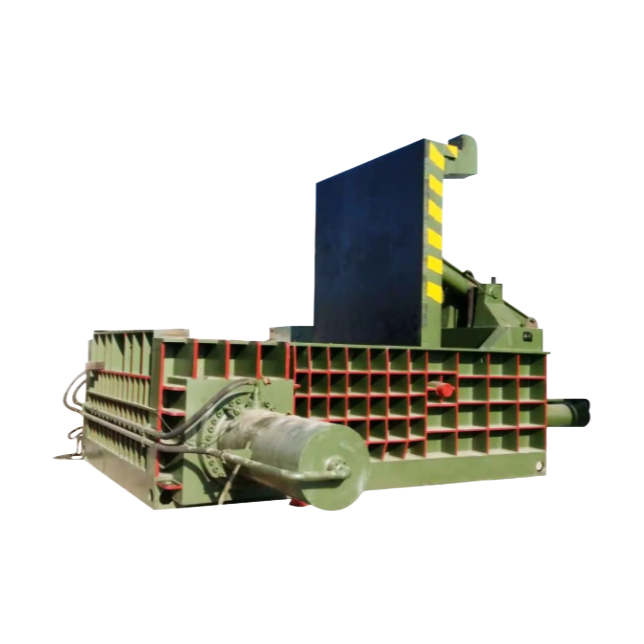

The hydraulic scrap metal baler is an industrial-grade compression equipment designed for metal processing and recycling facilities. This heavy-duty machine effectively compacts various metal scraps including aluminum cans, steel parings, copper waste and other metal leftovers into dense, transport-friendly bales.

Our metal baler series features robust construction with horizontal structure design, available in turn-out, side push-out or forward-out discharge configurations. The compression chamber can be customized to produce square, rectangular, octagonal or cylindrical bales according to specific requirements.

Key advantages of our hydraulic metal balers include high compression ratio for maximum density, energy-efficient operation, and optional automatic PLC control system for improved productivity. The machines are built with durable components to withstand continuous industrial use in demanding recycling environments.

Applications include processing of beverage cans, aluminum scraps, steel bars, stainless steel pipes, metal plates, and various metal scraps from manufacturing processes. The compacted bales significantly reduce storage space and transportation costs.

Optional features include cutting blades for processing longer metal pieces, material feeding systems, and customized hydraulic configurations to meet specific production requirements. All machines undergo strict quality control and testing before delivery.

Communication from the company was consistently clear and professional. They provided excellent support throughout the entire process, from initial inquiry to post-delivery follow-up. The packaging was robust and secure, ensuring the machine arrived in perfect condition without a single scratch. The build quality is immediately apparent; it feels solid, well-engineered, and precisely manufactured. The delivery was remarkably prompt, arriving well ahead of the estimated schedule, which was a fantastic surprise. Coordination with the shipping logistics was seamless, and the freight company they partnered with was efficient and communicative. Every interaction with their service team was positive; they were knowledgeable, patient, and genuinely helpful. Considering the factory-direct model, the value for money is outstanding. The entire experience, from ordering to unboxing, was smooth and hassle-free. I am thoroughly impressed and would not hesitate to recommend them to anyone in need of reliable industrial equipment. This was a completely satisfactory transaction from start to finish.

Logistics were handled exceptionally well. The shipping process was transparent and updates were provided regularly, which made planning for the arrival straightforward. The carrier was professional and the packaging was robust, ensuring the equipment arrived in perfect condition without any delays or complications. Quality is immediately apparent upon inspection. The construction is solid and the components feel durable, reflecting a high standard of manufacturing. The machine appears built to withstand rigorous industrial use, and the finish is clean and professional. Service from the initial inquiry through to post-delivery has been outstanding. The sales team was knowledgeable and responsive, answering all questions promptly without any pressure. They provided clear documentation and were very accommodating in arranging the shipment. Overall, this was a very positive experience from start to finish. The combination of efficient logistics, apparent product quality, and attentive service makes this supplier highly recommendable for anyone in need of reliable industrial equipment. The entire process was smooth and instilled confidence in both the product and the company behind it.

I was thoroughly impressed with the shipping speed for this order. The logistics were handled exceptionally well, with clear tracking updates provided at every stage. The packaging was robust and secure, ensuring the equipment arrived in perfect condition without any signs of damage from transit. Regarding the build quality, the machine appears very solid and well-constructed from heavy-duty materials, exactly as described. The overall service from inquiry to delivery was professional and responsive. Any questions I had were answered promptly and courteously. It was a smooth and satisfactory purchasing experience from start to finish.

Just outstanding experience from start to finish! The delivery was incredibly fast and well-organized, with the item arriving ahead of schedule and in perfect condition. The packaging was secure and professional, ensuring no damage during transit. In terms of quality, the machine feels robust and well-crafted, with attention to detail that speaks volumes about durability. Customer service was top-notch too; the team was responsive, friendly, and went above and beyond to address my queries promptly. Overall, I'm thoroughly impressed and would highly recommend this for anyone seeking reliable equipment.

Brisk delivery was a pleasant surprise; the item arrived much earlier than anticipated. The build quality is robust and durable, exceeding my expectations for such industrial equipment. Customer service was exceptionally helpful, promptly addressing my inquiries with clear and friendly responses. Overall, a very satisfying experience from start to finish.

Zipping through the delivery process, the logistics were incredibly efficient and timely, which made the entire experience smooth and hassle-free. Zero delays or issues with shipping, and the packaging was secure, ensuring everything arrived in perfect condition. Zestfully, the quality of the machine appears robust and well-constructed, meeting my expectations for industrial-grade equipment. Zoning in on customer service, the support team was responsive and helpful, addressing my inquiries promptly with clear communication. Overall, a very satisfactory purchase from start to finish, with no complaints whatsoever.

Massive appreciation for the exceptional logistics and service provided! The delivery was incredibly prompt and well-organized, arriving ahead of schedule without any hiccups. Every step of the shipping process was communicated clearly, making it stress-free. Moreover, the quality of the machine appears robust and well-crafted upon initial inspection, which gives me confidence in its durability. The customer service team was highly responsive and professional, addressing all my queries swiftly. Overall, a fantastic experience from start to finish—highly recommended for anyone seeking reliable equipment with top-notch support.

Fantastic experience with this purchase! The delivery was incredibly fast and well-handled, arriving ahead of schedule without any hiccups. The packaging was secure and professional, ensuring the machine was in perfect condition upon arrival. In terms of quality, the build is robust and durable, clearly made with high-grade materials that promise long-term reliability. The service provided by the team was outstanding; they were responsive, helpful, and went above and beyond to answer all my queries promptly. Overall, a seamless process from order to delivery, and I highly recommend this for anyone in need of reliable recycling equipment.

Could not be more satisfied with the entire experience. Communication was prompt and clear from the very beginning, which made the process smooth and stress-free. The shipping was incredibly fast, arriving well ahead of the estimated delivery date, and everything was packaged securely to prevent any damage during transit. The quality of the machine is outstanding—it feels robust and well-built, with attention to detail that speaks volumes about the craftsmanship. Customer service was exceptional; they were responsive, helpful, and went above and beyond to address my inquiries. Overall, a fantastic purchase that I would highly recommend to others.

Xcellent experience with this purchase! The delivery was incredibly fast and efficient, arriving ahead of schedule with secure packaging that ensured the machine was in perfect condition upon arrival. The quality of the hydraulic scrap metal baler is outstanding; it feels robust and well-constructed, clearly built to last in an industrial setting. Customer service was also top-notch—responsive, professional, and helpful throughout the process. Overall, I'm thoroughly impressed and would highly recommend this supplier to others in the recycling industry.