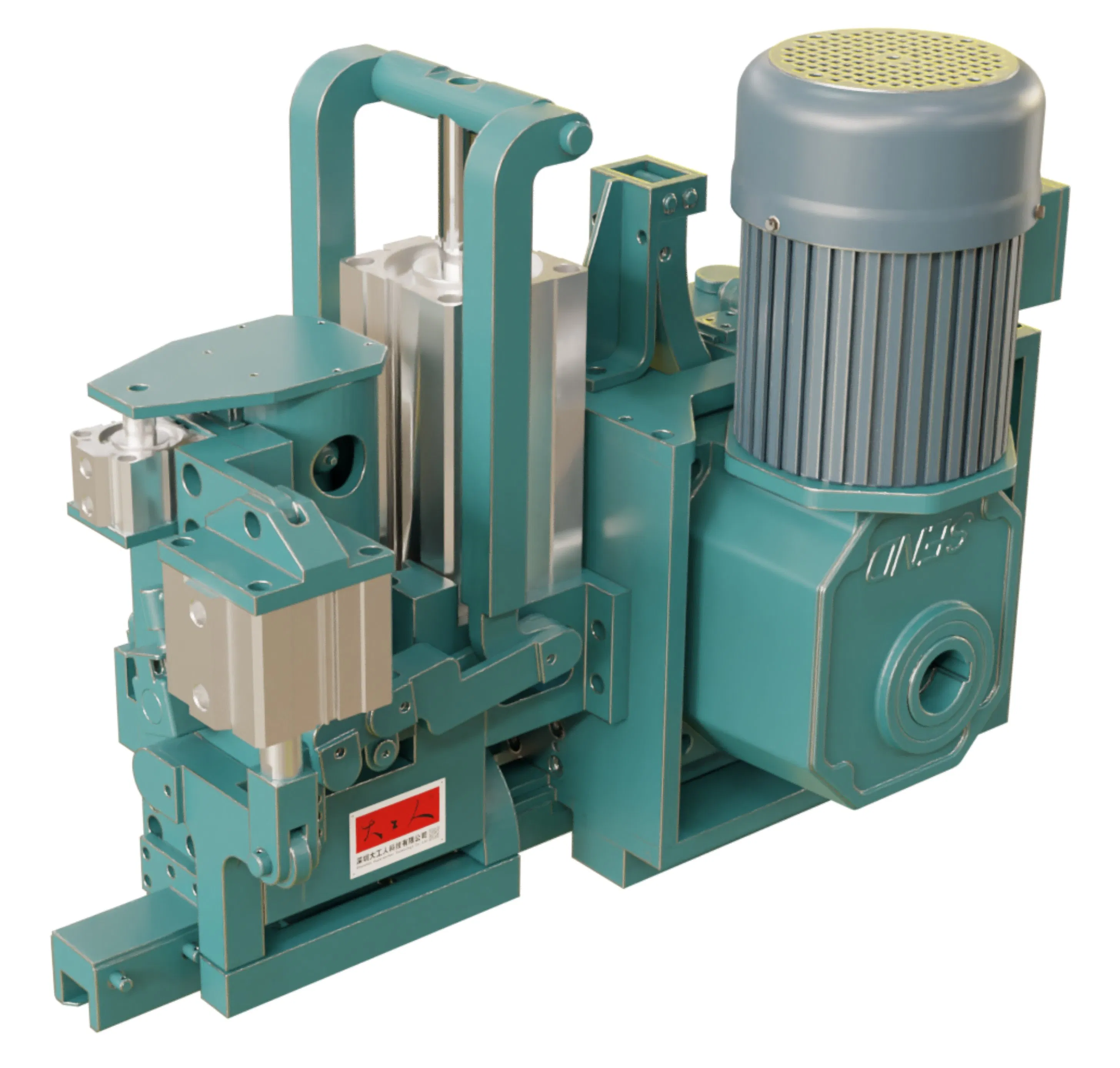

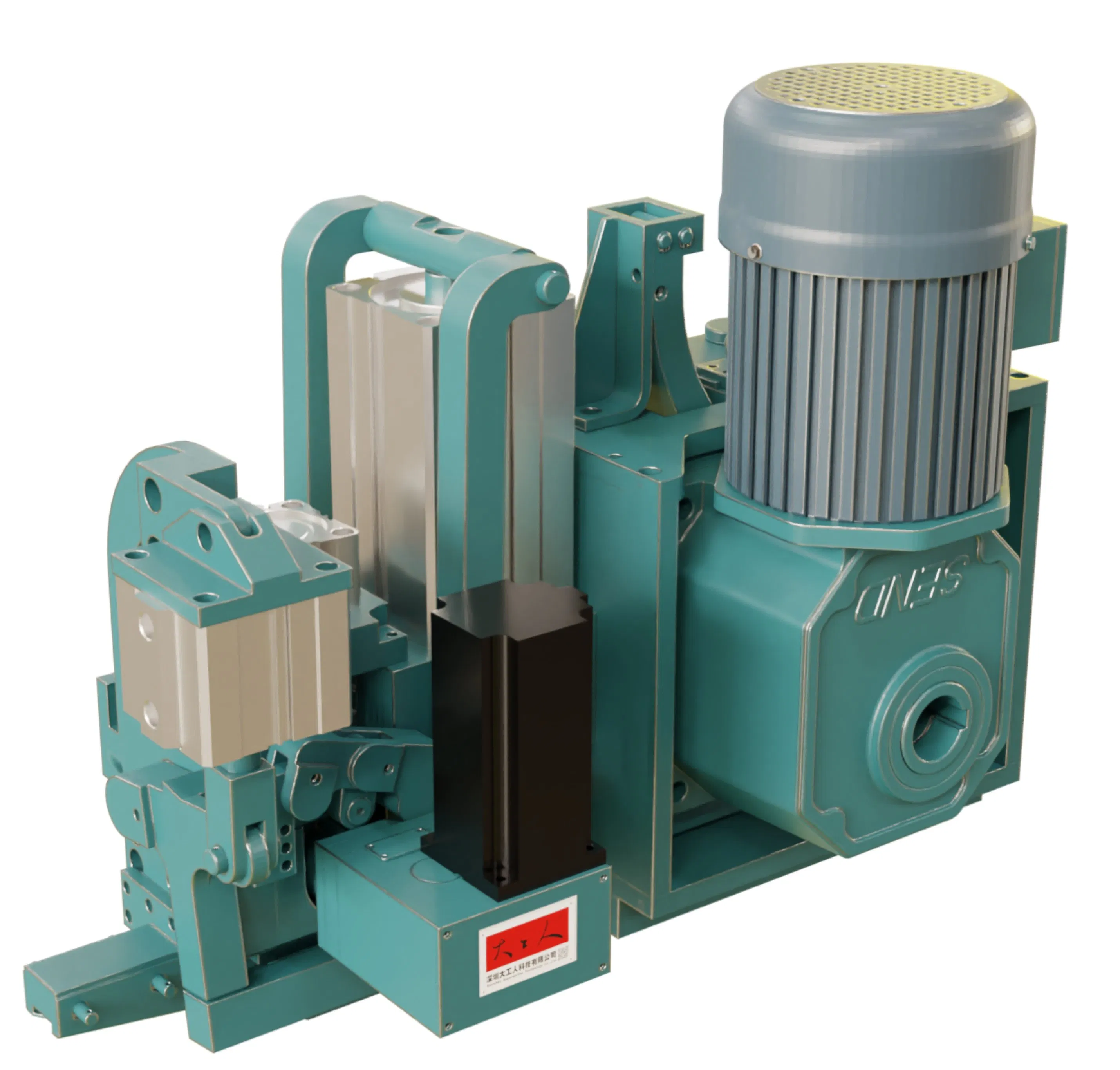

The DGR-IIIA Automatic PET Belt Strapping Machine is an advanced industrial packaging solution designed specifically for the metal industry. This friction welding type machine offers superior performance in bundling various metal products including galvanized coils, steel pipes, and aluminum ingots.

This strapping machine maintains 5% tightening force long-term without loosening, with a 5% buffer extension rate to ensure package safety. The PET strapping material eliminates sharp edges, protecting both packaged goods and operators during the packing process.

Key features include instantaneous welding through friction heating at overlapping PET belts, adjustable tension up to 10000N, and compatibility with belt widths of 19mm, 25mm, and 32mm (thickness 0.8-1.2mm). The machine operates efficiently in normal temperature environments with a strapping speed of 9.8 seconds per belt.

The equipment is manufactured according to strict metallurgical industry standards, capable of operating in demanding industrial environments. The PET belt joint strength exceeds 90% of the belt's original strength, ensuring secure bundling for heavy metal products.

With its electric and pneumatic driven system (380V AC/DC), this strapping machine represents a reliable solution for industrial packaging needs, combining efficiency with durability for continuous operation in metal processing facilities.

Unexpectedly swift delivery was the first highlight of my experience. The logistics were handled impeccably, with the item arriving well ahead of the estimated schedule, which was a tremendous help for our tight production timeline. Upon unboxing, the build quality immediately stood out; it feels exceptionally robust and precisely engineered, exactly as described for heavy-duty industrial use. The customer service team deserves special mention for their proactive and clear communication throughout the process. They were readily available to confirm shipping details and followed up to ensure everything was on track. This combination of efficient logistics, superior construction, and attentive support made the entire procurement process seamless and highly satisfactory. I am thoroughly impressed and would not hesitate to recommend this supplier based on this experience alone.

Very impressed with the overall experience. The delivery was remarkably swift and handled with great care, arriving ahead of the estimated schedule without any damage to the packaging. The quality of the strapping machine head appears robust and precisely manufactured, meeting the high standards expected for industrial equipment. Customer service was proactive and communicative, providing clear updates and promptly answering all preliminary queries. The entire process, from order to arrival, was seamless and professional. This level of execution in logistics and support instills significant confidence in the supplier and their products. A highly satisfactory transaction that sets a positive precedent for future business.

Excellent experience from start to finish. The shipping was remarkably fast and the item arrived well ahead of the estimated schedule, which was a fantastic surprise. Everything was packaged with exceptional care, ensuring the machine arrived in pristine condition without a single scratch or dent. The build quality is immediately apparent; it feels incredibly robust and well-engineered, exactly as described for heavy-duty industrial use. Customer service was equally impressive, providing clear and prompt communication throughout the entire process. They were very helpful in confirming order details and shipping timelines. While I haven't had the chance to put the machine through its paces on the production floor yet, the initial inspection leaves me thoroughly satisfied with the purchase. The overall presentation, from the packaging to the unit itself, speaks volumes about the manufacturer's attention to detail. This level of service and product presentation is commendable and sets a high standard. I am confident this equipment will integrate seamlessly into our packaging line. A very smooth and professional transaction overall.

Prompt delivery and excellent logistics handling. The shipping was faster than anticipated, and the packaging was secure, ensuring the product arrived in perfect condition. Communication regarding the shipment status was clear and timely. The quality of the strapping machine head appears robust and well-manufactured, exactly as described. The service from the seller was professional and responsive, answering all pre-purchase queries efficiently. Overall, a very satisfactory purchasing experience from start to finish. The entire process was smooth, and the product seems to be a solid piece of industrial equipment. I am confident in its durability and performance based on initial inspection. The seller clearly prioritizes customer satisfaction through reliable logistics and high-quality offerings. This transaction sets a high standard for online purchases of specialized industrial machinery. I would not hesitate to order from this supplier again in the future. The combination of speed, quality, and service is commendable. It’s refreshing to have such a seamless experience when ordering critical equipment for business operations. Every aspect, from the order placement to the final delivery, was handled with utmost professionalism. The product itself looks precisely as advertised, with no visible defects or issues. This level of attention to detail in both the product and the service is highly appreciated. A truly positive experience that I am happy to recommend to others in need of similar industrial solutions.

Smooth and efficient delivery was the first thing I noticed. The shipping process was remarkably fast, and the packaging was exceptionally secure, ensuring the machine arrived in perfect condition without a single scratch. This level of logistical care immediately set a positive tone. Regarding the build quality, it is outstanding. The machine feels solid and robust, clearly constructed from high-grade materials that inspire confidence for long-term industrial use. The overall craftsmanship is precise and professional. As for the service, the support team was responsive and helpful from the initial inquiry through to post-delivery follow-up. They provided clear communication and were proactive in ensuring everything was on track. A truly seamless experience from start to finish, highly satisfactory in every aspect that matters for a business purchase.

Perfect experience from start to finish. The shipping was incredibly prompt, arriving well ahead of the estimated schedule, which was a fantastic surprise. The packaging was secure and professional, ensuring the machine head arrived in pristine condition without a single scratch. Regarding quality, the construction feels exceptionally robust and durable, exactly as described for heavy-duty industrial use. The materials used seem top-notch, promising longevity and reliable performance in our demanding workshop environment. Customer service was equally impressive; the support team was responsive and knowledgeable, answering all pre-purchase queries thoroughly and with great patience. The overall process was seamless, and the product appears to be a solid, well-manufactured piece of equipment. Very satisfied with this purchase and the company’s professionalism.

Wanted to share my thoughts on the recent delivery of the strapping machine head. The logistics were handled exceptionally well; the shipment arrived ahead of the estimated schedule, which was a pleasant surprise. The packaging was robust and secure, ensuring the item was well-protected during transit. In terms of quality, the construction feels solid and durable, exactly as described. The service provided throughout the ordering process was commendable; the support team was responsive and helpful with my inquiries. Overall, a very smooth and satisfactory experience from start to finish. I am confident in the product and the company based on this interaction.

Wrapping up my thoughts on this purchase, I must highlight the exceptional aspects that stood out. The delivery was remarkably swift and efficient, arriving well ahead of schedule, which minimized any downtime in our operations. The packaging was secure and professional, ensuring the item reached us in pristine condition without any damage. In terms of quality, the construction feels robust and durable, with solid materials that suggest it will withstand heavy industrial use over time. The service provided by the seller was outstanding—prompt responses to inquiries, clear communication throughout the process, and a willingness to assist with any concerns. Overall, a seamless experience from order to receipt, making it a reliable choice for anyone in need of such equipment.

Shipping was incredibly fast and well-handled, with the item arriving ahead of schedule in perfect condition. The quality of the strapping machine head appears robust and durable, showing no signs of defects upon inspection. Customer service was outstanding; the support team responded promptly to my inquiries and provided helpful guidance throughout the process. Overall, I'm thoroughly satisfied with the seamless experience from order to delivery.

Wow, the shipping was incredibly fast and well-handled, with the package arriving securely without any delays. The build quality feels robust and reliable, showing excellent craftsmanship that should hold up well in industrial settings. Customer service was responsive and helpful, promptly addressing my inquiries with clear, friendly communication. Overall, a very satisfying experience that I'd happily recommend to others.