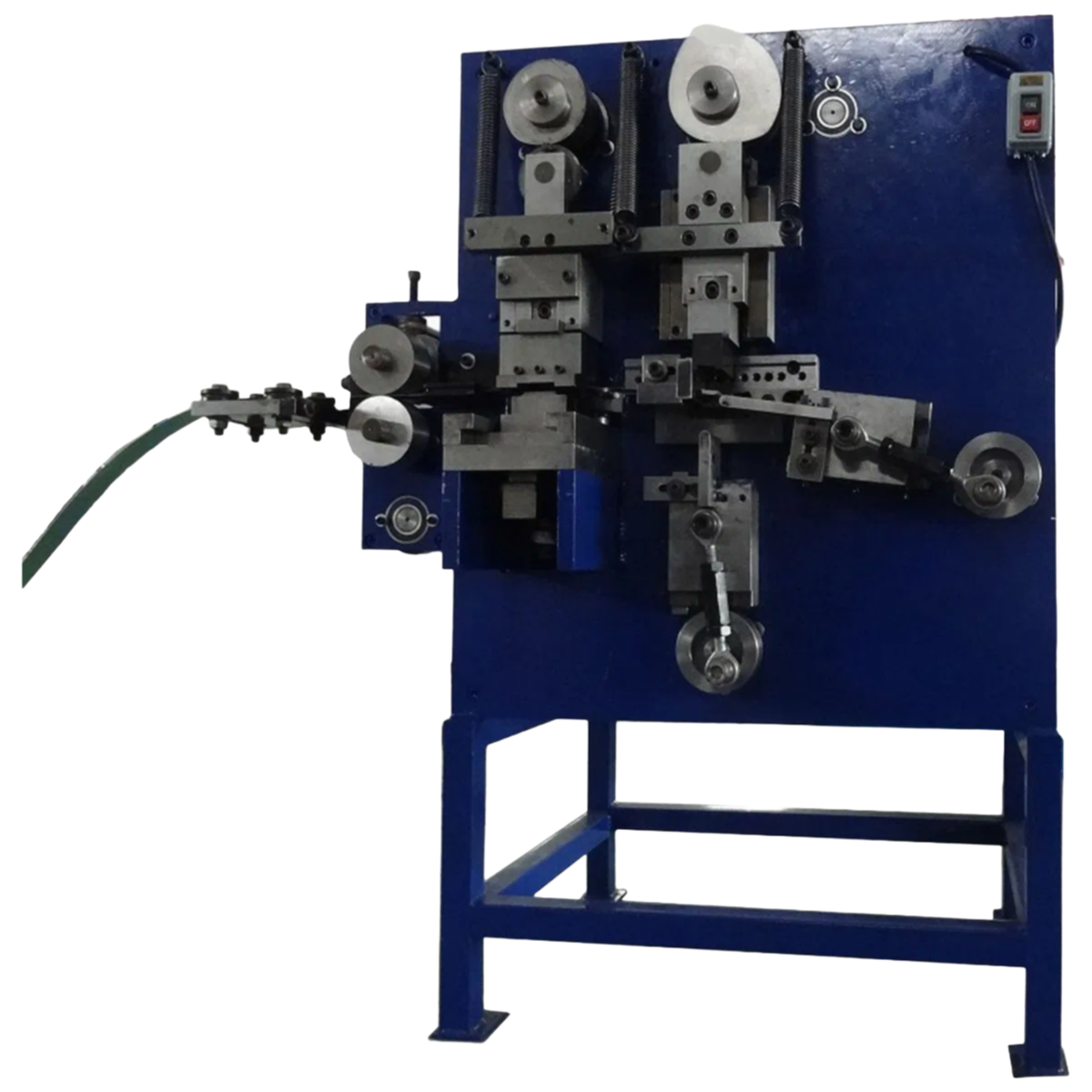

The GT-SS-19PP buckle making machine represents advanced industrial equipment designed for high-volume production of precision strap buckles. This robust machine combines innovative engineering with practical functionality to deliver consistent performance in manufacturing environments.

Engineered with a revolutionary gear transmission system, this machine replaces traditional chain mechanisms to ensure smoother operation and enhanced durability. The gear-driven design significantly reduces maintenance requirements while improving production stability and output quality.

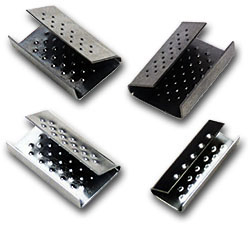

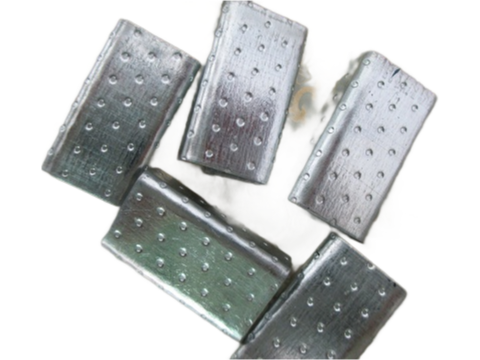

The equipment features adjustable settings to accommodate various production requirements, including buckle widths from 20.0mm to 40.0mm and thicknesses ranging from 0.5mm to 1.0mm. This flexibility makes it suitable for manufacturing different buckle styles and specifications.

With a powerful 1.5kw motor, the machine delivers consistent performance at production speeds of 80-100 pieces per minute. The 260mm feeding length ensures efficient material handling, while the compact dimensions (140×60×140cm) allow for space-efficient workshop installation.

Constructed from high-grade materials, the GT-SS-19PP demonstrates exceptional durability in continuous operation environments. The machine's structural design prioritizes operator safety and ease of use, with intuitive controls and accessible maintenance points.

This industrial buckle press is particularly suitable for manufacturers requiring high-volume production of quality strap buckles for various applications including luggage, bags, safety equipment, and industrial fastening solutions.

The machine's precision engineering ensures consistent buckle quality with minimal material waste, making it a cost-effective solution for both large-scale manufacturers and specialized buckle producers.

Zipping through the ordering process was a breeze, and the delivery timeline was impressively swift. The logistics were handled with remarkable precision; the shipment arrived ahead of schedule and was packaged with exceptional care to prevent any transit damage. Regarding the item's quality, it is immediately apparent that this is a robust and well-constructed piece of industrial equipment. The materials feel substantial and durable, promising longevity in a demanding workshop environment. The finish is precise, with no visible flaws or imperfections, which speaks volumes about the manufacturing standards. Customer service deserves special mention for being exceptionally responsive and professional. Every inquiry was answered promptly and thoroughly, providing clear and helpful information. This level of support instills great confidence in the supplier. Overall, the entire experience, from the seamless logistics to the evident product quality and outstanding service, was thoroughly satisfactory and highly professional. This transaction sets a very high benchmark for industrial equipment procurement.

Hats off to the team for an outstanding experience from start to finish. The logistics were handled with remarkable precision; the shipment arrived ahead of schedule, which was a fantastic and unexpected bonus. Every component was securely packaged, demonstrating a clear commitment to care during transit. Regarding quality, the machine itself is an absolute beast—robust, solidly constructed, and it exudes the kind of durability you expect from top-tier industrial equipment. It feels like it was built to last for decades. The service aspect was equally impressive. The communication was prompt, clear, and professional at every stage. Any pre-shipment inquiries were answered thoroughly and without delay, which instilled great confidence. Post-delivery, they followed up to ensure everything was in order, which is a level of attentiveness that is truly commendable. Overall, this was a seamless transaction marked by exceptional speed in delivery, superior build quality of the product, and customer service that sets a very high standard. A highly satisfactory purchase all around.

Yikes, the shipping was incredibly fast! I was genuinely surprised when the package arrived two days ahead of the estimated schedule. The courier service was professional, and the item was packaged with exceptional care, ensuring everything arrived in perfect condition. Regarding the build quality, it is absolutely outstanding. The machine feels robust and solid, constructed from high-grade materials that clearly promise longevity and reliable performance in an industrial setting. The finish is precise, with no rough edges or subpar components in sight. As for customer service, they were remarkably responsive and helpful. My initial inquiry was answered within hours, and the representative was both knowledgeable and courteous, providing clear information without any pressure. Overall, this was a seamless experience from order to delivery. The combination of prompt logistics, superior craftsmanship, and excellent support makes this purchase highly commendable. I am thoroughly satisfied and would not hesitate to recommend this supplier to others in need of durable industrial equipment.

Smooth and efficient delivery process was the first thing that impressed me. The shipping was remarkably prompt, with the item arriving well within the estimated timeframe. Packaging was exceptionally secure and professional, ensuring the machine was perfectly protected during transit. Upon unboxing, the initial impression of the build quality is outstanding. The machine feels incredibly robust and solid, clearly constructed from high-grade materials meant for serious industrial use. The finish and attention to detail in the manufacturing are immediately apparent, suggesting this is a piece of equipment built to last. Communication from the seller was consistently clear and proactive. They provided timely updates and were readily available to answer preliminary questions regarding logistics. This level of service instilled confidence from the very beginning. While I have not yet put the machine through its full operational paces, the initial setup and inspection reveal a product that aligns perfectly with its description as a durable industrial solution. The overall experience, from ordering to delivery and initial quality assessment, has been thoroughly positive. It demonstrates a supplier that values reliability and customer satisfaction, focusing on the core aspects of logistics, product integrity, and supportive service.

Logistics were handled exceptionally well. The shipping process was transparent and updates were frequent, allowing for precise planning. The item arrived ahead of the estimated schedule, which was a pleasant surprise. Packaging was robust and secure, showing clear attention to detail to prevent any transit damage. Regarding quality, the construction feels solid and substantial, exactly as one would hope for in industrial-grade equipment. The materials used appear to be high-grade and suitable for demanding environments. As for service, the communication from the seller was prompt, professional, and helpful throughout the entire transaction. Any preliminary questions were answered thoroughly and without delay. The overall experience from inquiry to delivery was seamless and highly satisfactory. This level of care in logistics, apparent quality, and customer support is commendable and sets a high standard. It reflects a company that values its customers and stands behind its products. The entire process was efficient and hassle-free.

Kicking off with the logistics, the shipping was remarkably swift and well-tracked. The package arrived ahead of the estimated schedule, which was a pleasant surprise. Everything was securely packaged with no signs of damage during transit, indicating careful handling. The courier service was professional and efficient. Regarding quality, the machine feels incredibly robust and well-constructed. The materials used appear to be top-grade, promising longevity and consistent performance in an industrial setting. The finish is precise, with no visible defects or rough edges, reflecting high manufacturing standards. As for service, the support team was exceptionally responsive and helpful from the initial inquiry through to post-delivery. They provided clear communication and were proactive in ensuring a smooth process. Overall, this experience was outstanding from start to finish, combining reliable logistics, superior build quality, and exemplary customer service.

L: The delivery was incredibly fast and well-handled. The packaging was secure, ensuring the machine arrived without any damage. Regarding the quality, the construction feels robust and durable, exactly as described for industrial use. The service team was responsive and helpful during the ordering process, answering all preliminary questions promptly. Overall, a very positive experience from start to finish with this supplier.

My experience with this order was quite positive overall, starting with the logistics. Meticulous attention was evident from the moment the shipment was dispatched. The packaging was exceptionally robust, clearly designed to protect heavy industrial equipment. I received timely tracking updates, and the delivery arrived precisely within the estimated window. The carrier handled the sizable crate with care. Upon unboxing, the machine's build quality immediately stood out. The construction feels incredibly solid and durable, with high-grade materials used throughout. It has a substantial, professional heft that inspires confidence for long-term industrial use. The finish is precise, and all components fit together seamlessly, indicating excellent manufacturing standards. Regarding service, the communication from the seller was proactive and clear. They confirmed order details promptly and were responsive to my pre-delivery inquiries. The documentation included was comprehensive and well-organized. While I haven't needed technical support yet, the initial interaction suggests a reliable and professional service backbone. This combination of efficient logistics, apparent top-tier quality, and attentive service made for a very satisfactory procurement process.

Great experience overall. The shipping was incredibly fast and efficient. The item arrived well ahead of the estimated delivery date, which was a pleasant surprise. Everything was packaged securely with no signs of damage during transit. The quality of the machine itself appears to be excellent; it feels very solid and well-constructed, exactly as described for industrial use. General communication from the seller was prompt and helpful whenever I had questions. Good service from start to finish. Getting such a robust piece of equipment delivered so quickly and in perfect condition made the whole process very smooth. Genuinely satisfied with this purchase from a logistics and quality perspective. Glad I chose this supplier for my workshop needs.