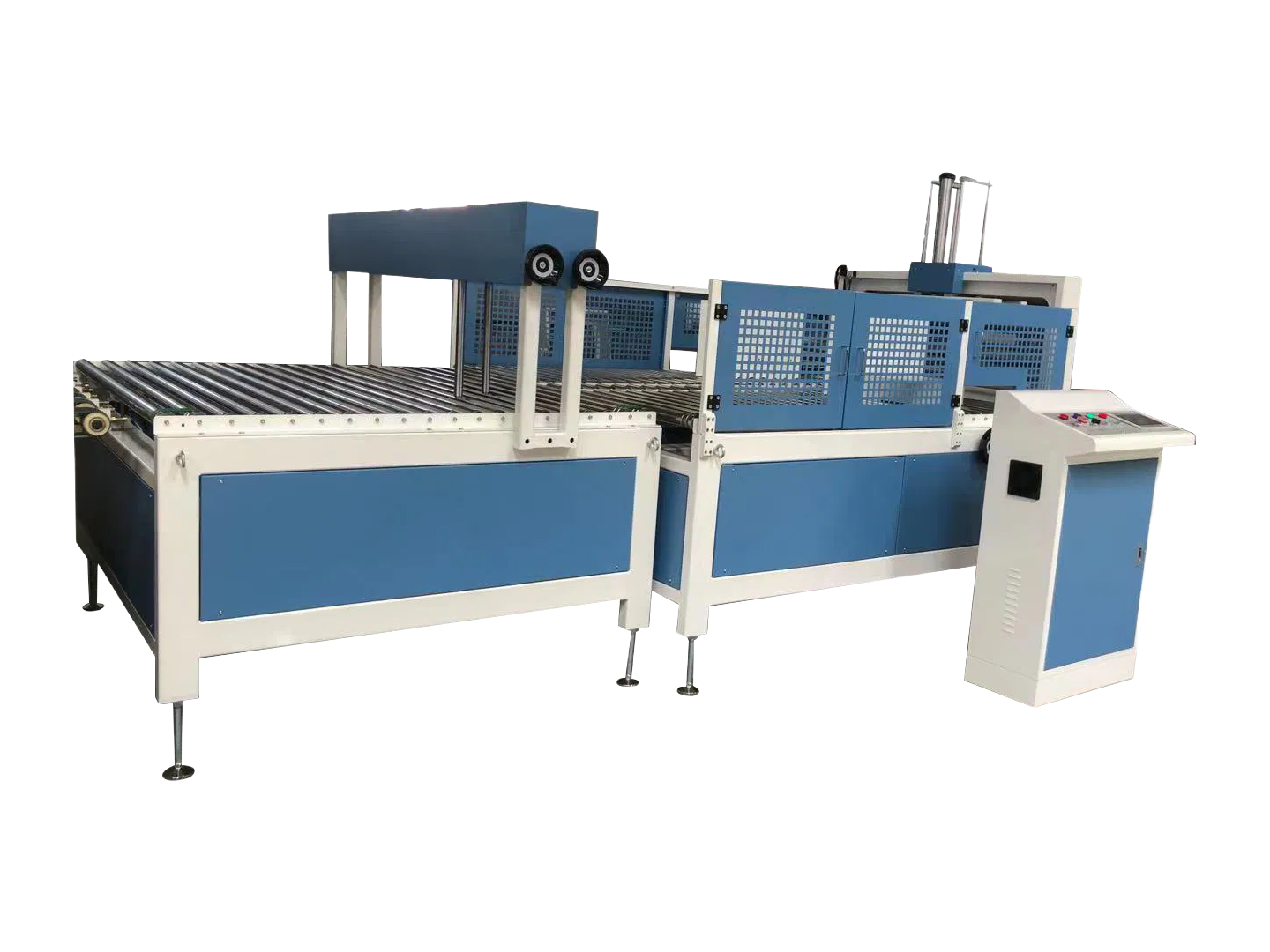

The automatic PP strapping machine is a robust and efficient solution for industrial packaging needs. It comprises three main units: a paper conveyor and steering unit, a gather align unit, and a no-man power strapping unit, forming a fully automatic assembly line that integrates machinery, electricity, and gas systems.

With PLC control, this machine offers stable performance and a fast packing speed, capable of handling 9 to 18 pieces per minute. It operates effectively in environments with relative humidity up to 90%, temperatures between 0-40 degrees Celsius, and noise levels not exceeding 75 dB (A). The standard bandwidth is 5mm, with an optional 9mm available, and it uses tape reels with an inner diameter of 200-210mm and outer diameter of 400-450mm.

The bonding method is hot fusion, ensuring a strong adhere with the bottom bonded, achieving a bonding surface of at least 90% and a position deviation of no more than 2mm. The bundling tightness ranges from 0 to 45Kg, providing secure fastening for various applications. Air source pressure is maintained between 0.5-0.8MPa, and the machine features stainless steel rollers with a diameter of 50mm and wall thickness of 1.2-1.5mm for durability.

Designed for versatility, the transportation speed is adjustable from 0 to 50m/min, making it suitable for different production lines. This machine is ideal for packaging corrugated cardboard and other materials, emphasizing high quality and ease of operation. It includes comprehensive after-sales support with video technical assistance and a one-year warranty on core components.

Images of the machine:

Xceptional delivery speed was the first thing I noticed; the logistics were seamless from start to finish. The equipment arrived well ahead of the projected schedule, which was a fantastic surprise and allowed us to begin integration planning immediately. Every component was securely packaged, with no signs of damage or mishandling during transit—a testament to careful shipping procedures. Regarding build quality, the machinery feels incredibly robust and precisely engineered. The materials used are top-notch, giving confidence in its durability for heavy industrial use. The finish on all metal parts is smooth, and the assembly shows a high level of craftsmanship with no loose fittings or rough edges. The overall construction appears designed to withstand a demanding production environment. On the service front, the support team was proactive and communicative. They provided clear documentation and were readily available to answer preliminary questions, making the pre-installation phase straightforward. While I cannot comment on operational performance yet, the unboxing and initial inspection experience has been thoroughly positive. The coordination between the shipping carrier and the supplier was flawless, ensuring a hassle-free receipt of the goods. This level of attention to logistics, apparent quality, and supportive service from the outset sets a very promising foundation for this automated packaging system.

Just received the automatic PP strapping assembly line, and I'm thoroughly impressed with the overall experience. The delivery was incredibly fast, arriving well ahead of schedule, which minimized any downtime in our operations. Everything was securely packaged, ensuring no damage during transit, and the logistics team provided timely updates throughout the shipping process. As for quality, the machine appears robust and well-constructed, with durable components that suggest it will handle heavy industrial use without issues. The service from the supplier was exceptional; they were responsive to inquiries and offered helpful guidance during setup. Overall, a seamless and reliable purchase that has already started to enhance our packaging efficiency.

Massive kudos to the team for an outstanding experience with the automatic PP strapping assembly line! The logistics were incredibly smooth and efficient; the equipment arrived well ahead of schedule and in perfect condition, which minimized our downtime significantly. Regarding quality, the build is robust and durable, clearly designed for heavy industrial use without any compromises. The service was top-notch as well—responsive, professional, and always ready to assist with any inquiries. Overall, a highly reliable and impressive system that has greatly enhanced our packaging operations.