Reverse Circulation (RC) drilling is an efficient method for collecting mineral and rock samples using large rotary drills and air compressors. This technique is widely used in mining exploration due to its cost-effectiveness and efficiency compared to other drilling methods.

RC drilling utilizes rods with inner and outer tubes, where drill cuttings are returned to the surface inside the rods. The drilling mechanism consists of a pneumatic reciprocating piston (hammer) that drives a tungsten-steel drill bit. This method is ideal for reaching depths of up to 500 meters and produces dry rock chips as large air compressors dry the rock ahead of the advancing drill bit.

Compared to core drilling, RC drilling offers faster penetration rates and several advantages including direct cost reductions (25-40%), faster completion of drill programs, reduced man-hours at the drill site, and simplified sampling processes. RC samples are collected directly at the drill and sent to the assay lab, resulting in faster turnaround times.

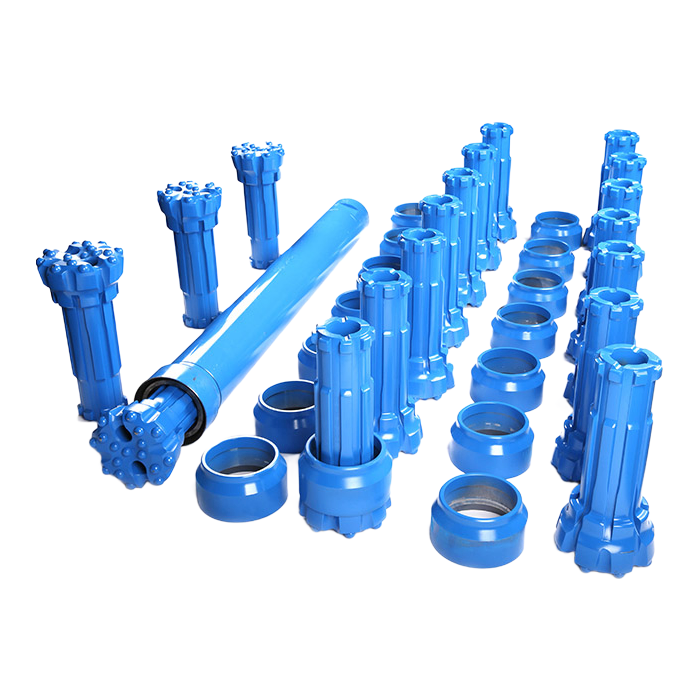

Our RC543 Reverse Circulation 5" DTH hammer and bits are manufactured from high manganese steel for durability and performance. These components are essential equipment for mineral exploration and mine development projects.

The RC drilling method is particularly valuable during in-pit grade control and the development stage of an ore body. It provides more representative samples than split half core samples while requiring less water than diamond drilling methods.