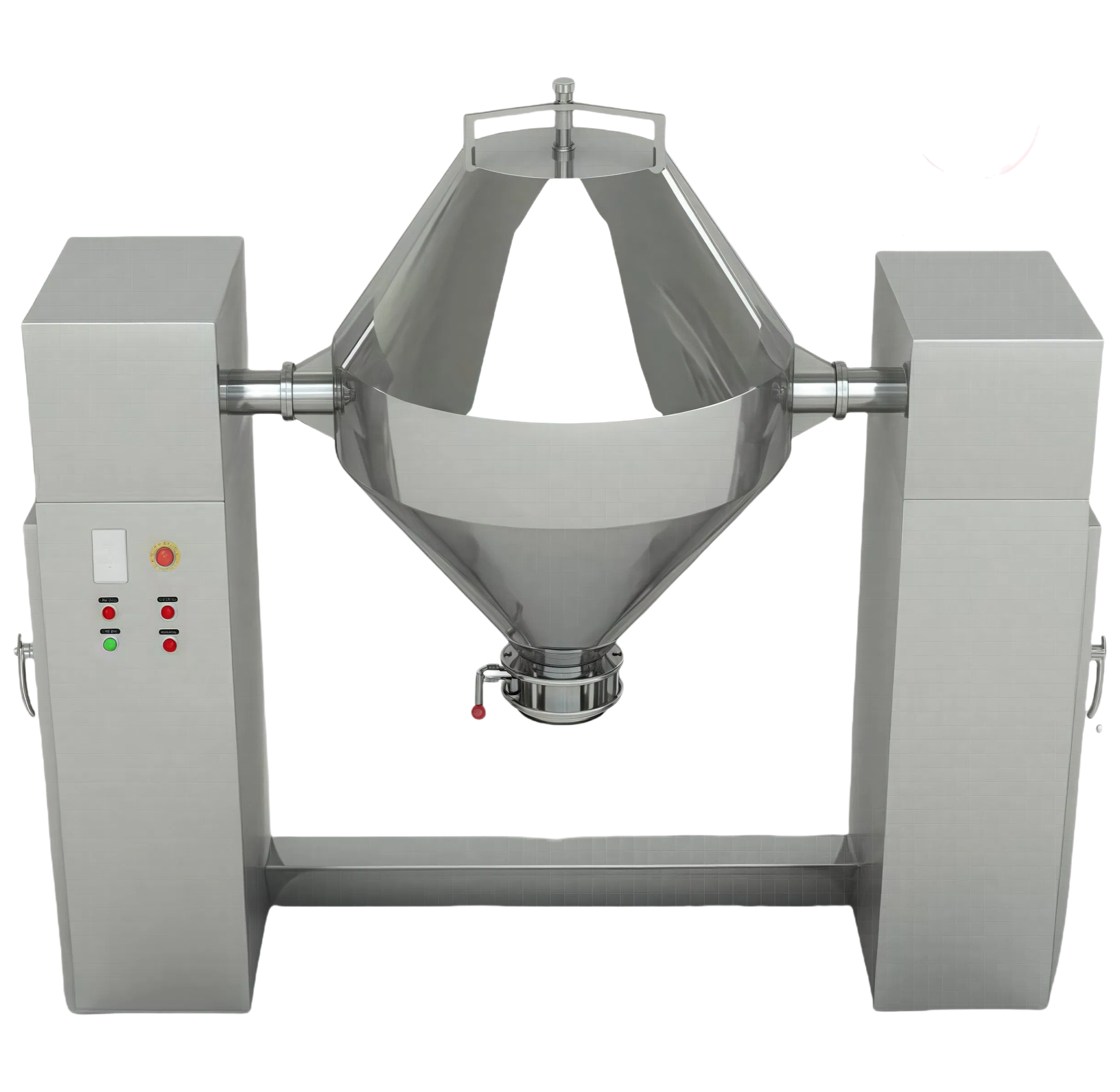

The double cone mixer operates through a motor and reducer system that drives the mixing tank via gear transmission. Prepared powders are loaded into the mixing tank, and the rotation of the tank causes materials to repeatedly aggregate and separate under gravity and centrifugal force, ensuring thorough and uniform mixing. Once mixed, materials are discharged through the outlet by their own weight.

This equipment boasts a compact structure, making it space-efficient and ideal for various industrial settings. Operation is straightforward with automated control options, reducing labor intensity. The mixer delivers excellent mixing results with high uniformity, suitable for a wide range of materials including powders, granules, and viscous fluids.

Applications span multiple industries such as pharmaceuticals, chemicals, food, feed, agricultural chemicals, daily chemicals, engineering, construction, metallurgy, and minerals. It is designed to meet GMP, C-GMP, and FDA certification standards, ensuring reliability and compliance.

Key components include a stainless steel tank with a short cylinder between two cones, typically at 90° or 75° angles for efficient discharge. The inlet and outlet are equipped with pneumatic or electric butterfly valves. The drive system consists of an electric motor, reducer, and transmission gear, allowing adjustable rotation speeds and automated control. A slip ring box manages power distribution for electrical components on the rotating tank, and a robust support stand holds the entire assembly securely.

Additional features may include heating and cooling systems, spray functions, and various internal stirring types like jiaolong, paddle, or spiral blades, enhancing versatility for different mixing needs. Safety features include emergency stop buttons and overload protection, ensuring safe operation in industrial environments.

This product is intended for industrial and research use only, not for personal applications. Customization options are available to meet specific production requirements, including various models with different capacities and configurations.

Logistics were handled exceptionally well. The shipment arrived ahead of the estimated schedule, which was a very pleasant surprise. Everything was packaged securely with no signs of damage during transit. The communication regarding shipping updates was clear and timely. Regarding quality, the construction of the mixer is immediately impressive. It feels robust and the stainless steel finish is clean and professional. All welds and fittings appear to be of high standard. As for service, the support team was responsive and helpful during the ordering process, answering all preliminary questions efficiently. Overall, a very smooth experience from start to finish.

Hands down, the shipping and logistics for this mixer were handled with incredible professionalism. From the moment the order was confirmed, I received timely updates, and the carrier was exceptionally careful during delivery. The packaging was robust and secure, ensuring the equipment arrived in pristine condition without a single scratch or dent. Regarding the build quality, it is immediately apparent that this is a heavy-duty piece of machinery. The stainless steel construction feels solid and premium, promising excellent durability for our demanding production environment. The welds are smooth, and the overall finish is impeccable. Finally, the customer service team deserves high praise. They were highly responsive, patient in answering all pre-purchase inquiries, and provided clear documentation. The post-delivery support has also been excellent, with prompt follow-ups to ensure everything was received correctly. A truly seamless experience from start to finish.

Outstanding experience with this purchase! The delivery was incredibly fast and well-handled, arriving ahead of schedule without any damage. The packaging was secure, ensuring everything was in perfect condition upon arrival. Quality-wise, the materials feel robust and durable, meeting high standards for industrial use. Customer service was exceptional; they were responsive, helpful, and resolved my queries promptly. Overall, a smooth and reliable process from start to finish. Highly recommend for anyone seeking efficient logistics and top-notch support.

Worth every penny for the exceptional delivery speed and secure packaging that ensured the mixer arrived in perfect condition. The quality is outstanding, with robust construction and smooth operation that meets high industrial standards. Customer service was responsive and helpful throughout the ordering process, providing clear updates and addressing my queries promptly. Overall, a reliable purchase with no issues in logistics, build, or support.

Hands down, the shipping was incredibly fast and reliable—my order arrived well ahead of schedule, which was a huge relief for our tight production timeline. The packaging was sturdy and secure, ensuring everything arrived in perfect condition without any damage. In terms of quality, the materials feel robust and durable, promising long-term use in our facility. Customer service was exceptional too; the team was responsive and helpful, answering all my queries promptly and professionally. Overall, a very satisfying experience from start to finish.

Absolutely fantastic experience with this purchase! The delivery was incredibly fast and efficient, arriving well ahead of schedule, which was a pleasant surprise. The packaging was secure and professional, ensuring everything arrived in perfect condition. As for the quality, it's top-notch—the materials feel durable and well-crafted, showing attention to detail. Customer service was outstanding; they were responsive and helpful throughout the process, making me feel valued as a customer. Overall, I'm highly satisfied and would recommend this to others without hesitation.

Keenly observed the delivery process, and the logistics were impressively swift, arriving ahead of schedule without any hiccups. The quality of the item is outstanding, with robust construction that feels durable and reliable. Customer service was exceptional, providing prompt and helpful responses to all my inquiries. Overall, a very satisfying experience from start to finish.

Zippy delivery impressed me right away—the shipment arrived days earlier than estimated, which minimized our project downtime. Zero issues with the packaging; everything was securely crated and clearly labeled for easy handling. Zesty communication from the sales team made the ordering process smooth—they promptly answered my queries and provided helpful updates. Zonal quality checks are evident in the sturdy stainless steel construction; it feels robust and built to endure heavy industrial use. Zenith service support followed up after delivery to ensure everything met expectations. Zilch complaints overall—this supplier excels in reliability and professionalism.