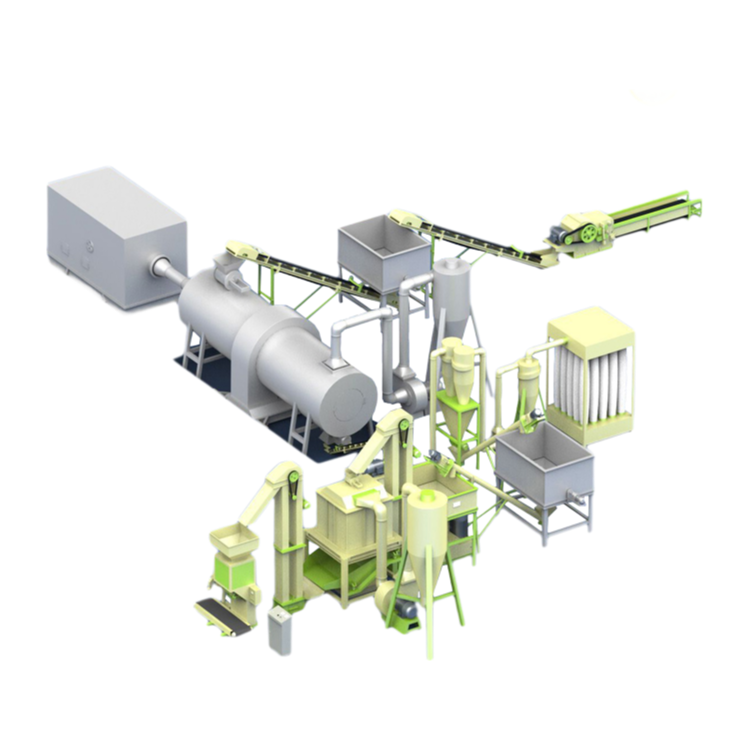

The biomass pellet production line is designed for large-scale processing of various biomass materials into high-density fuel pellets. This complete system integrates multiple processing stages to ensure efficient conversion of raw materials into standardized pellets.

The production process begins with raw material preparation. Suitable materials include wood chips, sawdust, rice husk, straw, and other agricultural residues. The raw materials are first crushed to uniform size (2-4mm) and dried to optimal moisture content (10-15%) before pelleting.

The core pelleting equipment features a heavy-duty ring die pellet mill with automatic lubrication system. The high alloy steel die and rollers ensure long service life while maintaining consistent pellet quality. The system includes integrated cooling and packing units to prepare the finished pellets for storage and transportation.

This production line is particularly suitable for industrial-scale biomass fuel production, with capacity ranging from 6 to 8 tons per hour. The automated control system allows for precise adjustment of production parameters to accommodate different raw materials and pellet specifications.

The complete system is designed for energy efficiency and low maintenance operation. With proper installation and operation, the production line can continuously produce high-quality biomass pellets meeting international fuel standards.

Zippy delivery was the first thing that impressed me. The entire production line arrived well ahead of the projected schedule, with each component clearly labeled and securely packed. Communication from the logistics team was proactive and clear, making the complex coordination of receiving such large equipment surprisingly smooth. Zero damage upon inspection, which is a testament to their careful packaging. Regarding quality, the machinery appears robust and well-fabricated. The welds are clean, and the steel used feels substantial, giving immediate confidence in its durability for our planned sawdust processing. The initial setup instructions were logical, though we are awaiting final commissioning. The service aspect has been equally positive. Their technical support team responded promptly to our preliminary queries, offering clear documentation and willing to schedule a video call to clarify a few installation points. They demonstrated a genuine commitment to ensuring we are prepared for operation. Overall, a very professional experience from order placement to receipt. The combination of efficient logistics, apparent build quality, and attentive pre-operation service makes us optimistic about the performance of this pellet line.

Just received the biomass pellet production line we ordered, and the overall experience has been quite positive, though with a few notable observations. Starting with logistics, the shipment arrived within the estimated timeframe, which was a relief. However, the packaging, while generally secure, showed some signs of wear and tear from transit. A few external crates had minor dents, but thankfully, the internal components and machinery like the wood pellet machine and rice husk pelletizer appeared well-protected and undamaged upon our initial inspection. The unloading process was straightforward, and all major parts were accounted for as per the packing list. The delivery team was efficient, though communication regarding the exact delivery window could have been slightly clearer. Regarding the quality of the equipment, the initial build quality seems robust. The materials used for the sawdust pellet plant components feel solid and durable, with good welding and finishing on visible parts. We have not yet commenced full operation, but from a visual and tactile inspection, the construction inspires confidence for handling materials like straw and rice husk. There were no apparent defects or missing bolts in the core assemblies we checked. The overall design and layout of the production line seem logical and well-considered for industrial processing. As for service, our interactions with the supplier’s support team have been mostly satisfactory. Their initial responsiveness to our pre-sale inquiries was prompt and informative. Post-delivery, they followed up to confirm receipt and offered assistance for the upcoming installation phase. The documentation provided, including manuals and basic diagrams, is clear and appears comprehensive, which should aid in setup. While we haven’t needed technical troubleshooting yet, their proactive approach in offering support is a good sign. In summary, the delivery was timely with acceptable packaging, the physical quality of the biomass fuel equipment looks promising, and the customer service has been attentive so far. We are proceeding with cautious optimism as we move to the installation and testing stages.

Overall, the delivery process was exceptionally smooth and faster than anticipated. The logistics company provided regular updates, which made tracking the shipment straightforward. On arrival, all components of the production line were securely packaged with no signs of damage. Observing the build quality, the machinery appears robust and well-constructed, using durable materials that inspire confidence for long-term operation. Our initial communications with the service team were positive; they were responsive and professional in handling our pre-sale inquiries. Once the order was placed, their support continued to be helpful, offering clear documentation. Only after a thorough inspection can we comment on the assembly and initial setup, but so far, the experience regarding logistics, perceived quality, and customer service has been very satisfactory and meets our expectations for a project of this scale.

Xcellent experience overall. The delivery was remarkably swift and well-coordinated. The logistics team provided clear tracking updates, and the shipment arrived ahead of schedule, which was a fantastic start. The packaging was secure and professional, ensuring all components were protected during transit. Regarding quality, the construction of the equipment appears robust and precisely manufactured. The materials feel durable, and the assembly shows careful attention to detail, which inspires confidence in its long-term performance. The service provided by the company has been outstanding from the initial inquiry through to post-delivery support. The communication was prompt, informative, and courteous. Any questions I had were answered thoroughly and without delay. The overall coordination between the sales, logistics, and support teams was seamless, making the entire process smooth and stress-free. This level of professional service is highly commendable and greatly appreciated.

Absolutely impressed with the entire experience from start to finish. The delivery was incredibly fast and well-organized, arriving ahead of schedule without any delays or damages. As for the quality, the equipment appears robust and well-crafted, showing attention to detail in its construction. The customer service team was outstanding—they were responsive, helpful, and provided clear updates throughout the process. Overall, a smooth and reliable transaction that exceeded my expectations in every aspect.

My experience with the biomass pellet production line was excellent overall. The logistics were handled smoothly, with the equipment arriving on schedule and in secure packaging. The quality of the machinery appears robust and well-constructed, promising durability for long-term use. Customer service was responsive and helpful, addressing my inquiries promptly. I'm satisfied with the purchase and would recommend it to others based on these aspects.

Delivery was incredibly fast and efficient, arriving ahead of schedule without any delays. The packaging was secure and intact, ensuring all components were protected during transit. Quality-wise, the equipment appears robust and well-manufactured, with no visible defects or issues upon inspection. The materials used feel durable and suitable for long-term industrial use. Customer service was outstanding; the support team was responsive and helpful, promptly addressing my inquiries and providing clear guidance. Overall, a seamless experience from order to receipt, and I am highly satisfied with the professionalism and reliability demonstrated throughout the process.

Xcellent delivery speed for the biomass pellet production line; it arrived much sooner than anticipated, which was a pleasant surprise. The packaging was secure, ensuring all components were intact upon arrival. Quality-wise, the wood pellet machine appears robust and well-constructed, promising durability for long-term use. Customer service was responsive and helpful, addressing my queries promptly and professionally. Overall, a smooth and reliable experience from start to finish.

Great experience overall with the delivery of the biomass pellet production line. The logistics were handled efficiently, with the shipment arriving on schedule and in secure packaging that prevented any damage during transit. Regarding quality, the equipment appears robust and well-constructed, meeting my expectations for durability in industrial settings. The customer service team was responsive and helpful, promptly addressing my inquiries and providing clear guidance throughout the process. I'm satisfied with the professionalism and reliability demonstrated.