The DEPAI DES320C rotary die cutting slitting machine is designed for high-efficiency processing of blank adhesive labels. This industrial-grade equipment combines die cutting and slitting functions in one compact unit, delivering precision results at speeds up to 100m/min.

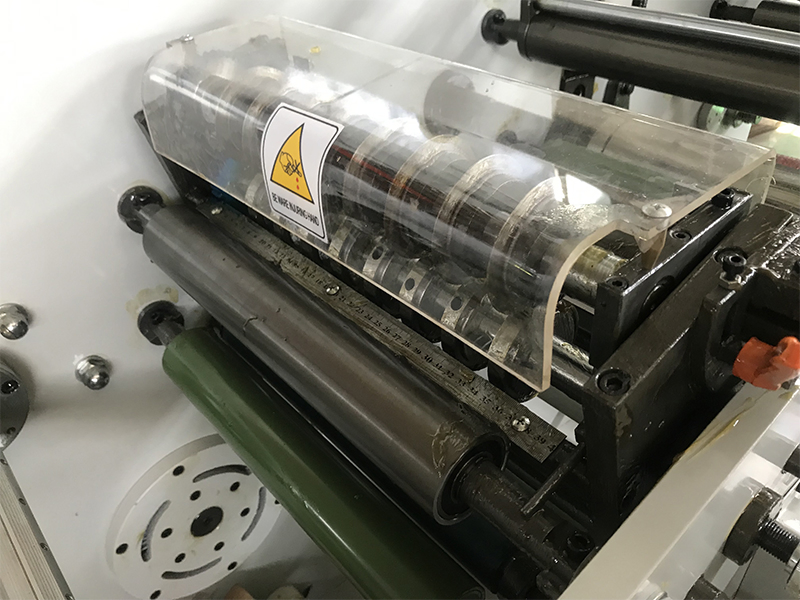

Featuring a computerized control system and steel blade cutting tools, the machine ensures consistent quality with ±0.10mm accuracy. The integrated photoelectric eye web guiding system maintains proper material alignment throughout the production process.

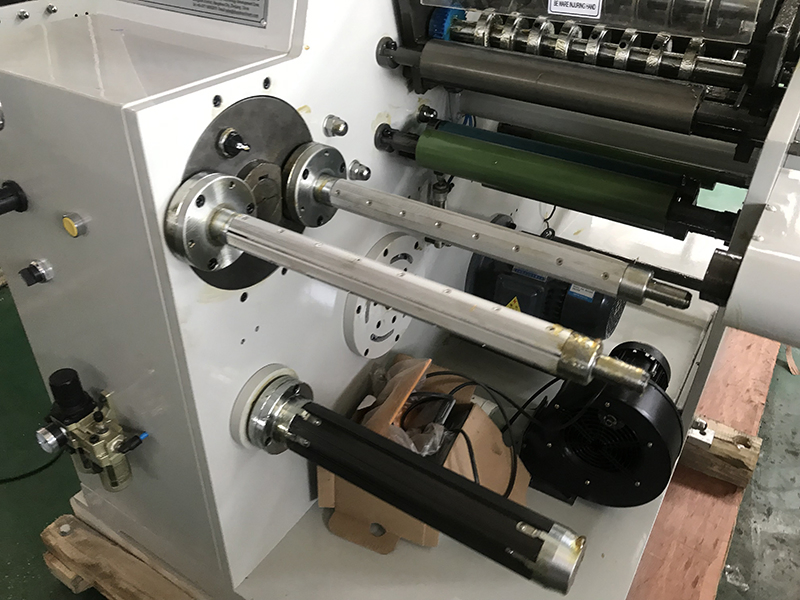

The standard configuration includes one slitting station, one rotary die cutting station with waste rewinder, and multiple rewinding shafts to accommodate different production needs. The built-in blower fan efficiently removes trimmed material edges during operation.

With its 320mm maximum working width and 700mm unwinding capacity, this machine handles medium to large production volumes. The compact footprint (1800×1100×1800mm) makes it suitable for various workshop environments.

The DES320C is particularly effective for creating custom-shaped labels, offering the flexibility to produce both simple geometric forms and complex designs. The rotary die cutting mechanism ensures continuous, high-speed production without sacrificing precision.

This industrial label processing equipment is built for durability with quality components including magnetic brakes and clutches for controlled operation. The 3kw main power motor delivers consistent performance for extended production runs.

Lately, I received the DEPAI rotary die cutting equipment, and the entire experience was quite positive. The logistics were handled exceptionally well; the shipment arrived ahead of schedule, which was a pleasant surprise given the size and complexity of the machinery. Everything was securely packaged, with no signs of damage during transit, reflecting careful handling and attention to detail from the shipping team. Regarding quality, the equipment feels robust and well-constructed, with solid materials that suggest durability and reliability for industrial use. The precision engineering is evident, and it seems capable of handling demanding production tasks efficiently. As for service, the support team was responsive and helpful, providing clear information and assistance when needed, which made the setup process smoother. Overall, this was a satisfactory purchase from a logistics, quality, and service perspective, and I look forward to seeing its performance in our label production line.

Q: The shipping was incredibly fast and well-handled. The equipment arrived securely packaged with no signs of damage, which was a major relief given the size and complexity of the machine. All components were present and clearly labeled, making the initial unpacking and inspection straightforward. The communication from the logistics team was proactive, providing timely tracking updates. Regarding quality, the construction of the rotary die cutting machine feels exceptionally robust and precise. The materials used appear to be high-grade, promising durability for heavy industrial use. The initial setup, while technical, was facilitated by clear, though not exhaustive, documentation. The service aspect has been satisfactory so far; initial inquiries were answered promptly, and the support team was knowledgeable. However, the true test of service will come during long-term operation and any potential maintenance needs. Overall, the process from order to delivery was seamless, and the product's physical quality meets professional expectations. The machine's performance in an actual production environment is yet to be fully assessed, but the initial impressions regarding its build and the efficiency of the delivery process are very positive. This experience fosters confidence in the supplier's ability to deliver substantial industrial equipment reliably.

Great experience overall. The shipping was incredibly fast and efficient, with the equipment arriving well ahead of the estimated schedule. Everything was packaged securely with no signs of damage during transit. The quality of the machine itself is immediately apparent; it feels robust, well-engineered, and precisely manufactured. Communication from the seller was prompt and helpful throughout the entire process, answering all pre-purchase questions clearly. The initial setup guidance provided was adequate. While I haven't put it through its full paces yet for a detailed performance review, the initial impressions regarding build and delivery are very positive. The logistical handling was seamless, and the unit's construction meets industrial expectations. Customer service was responsive and professional, making the procurement process straightforward. The packaging integrity upon arrival reflected careful preparation. This initial phase of receiving and inspecting the equipment has been smooth and satisfactory, instilling confidence in the purchase. The delivery personnel were also courteous and handled the shipment with care. Overall, a very good start in terms of logistics, perceived quality, and supplier interaction.

Just outstanding from start to finish. The delivery was incredibly prompt and handled with the utmost care. The packaging was secure and professional, ensuring the equipment arrived in pristine condition without a single scratch. Regarding the quality, it is immediately apparent that this is a robust and precision-engineered piece of industrial machinery. The build feels solid, and the components are clearly top-tier. The service provided was equally impressive; the communication was clear, responsive, and helpful throughout the entire process. Any pre-delivery questions were answered thoroughly and promptly. The overall experience was seamless and highly professional. This transaction has set a very high standard, and I would not hesitate to recommend this supplier to others in need of reliable industrial equipment. The combination of efficient logistics, superior product quality, and excellent customer service is truly commendable and rare to find all in one place.

Just outstanding performance from start to finish. Journey of the delivery was remarkably swift and well-tracked, arriving ahead of the projected schedule. Packaging was secure and professional, ensuring everything was in perfect condition upon unboxing. Quality of the machinery itself is immediately apparent; it feels robust, well-engineered, and precisely manufactured. Service provided by the team was equally impressive, with clear communication and helpful support during the initial stages. Judging by the seamless logistics, the superior construction, and the attentive customer service, this purchase represents exceptional value. Joyful to report a completely smooth transaction and a product that appears built to last for demanding industrial applications. Genuinely pleased with this acquisition and confident in its capabilities for our label production needs.

Quick delivery and excellent packaging ensured the machine arrived safely and on schedule. The overall build quality feels robust and professional, exactly as described for industrial use. Customer service was responsive and helpful during the setup inquiry. Quite satisfied with this purchase for our label production needs.

I was thoroughly impressed with the entire process. The shipping was incredibly fast and well-handled; the equipment arrived securely packaged and ahead of the estimated schedule. The build quality of the machine is exceptional, feeling robust and precisely engineered right out of the crate. Customer service was proactive and helpful, answering my preliminary questions promptly and clearly. While I haven't put it into full production yet, the initial setup and inspection have been very positive. The overall experience from ordering to delivery was seamless and professional. This level of care in logistics and initial support gives me great confidence in the product and the company behind it. I am looking forward to integrating this machine into our workflow.

Delivery was incredibly prompt and well-handled. The logistics team provided clear tracking updates, and the equipment arrived securely packaged without any delays. The build quality of the machine is immediately apparent; it feels robust and precisely engineered. Customer service has been responsive and helpful, answering all pre-purchase questions thoroughly. Overall, a very smooth transaction from start to finish.

Came exactly as described. The shipping was incredibly fast and well-handled; the equipment arrived securely packaged with no signs of damage during transit. Communication from the seller was prompt and clear throughout the entire process, which made the experience very smooth. The build quality of the machine itself appears robust and meets industrial standards. Initial setup was straightforward with the provided documentation. Overall, a very satisfactory purchase from a reliable supplier.

I recently received my order for the DEPAI rotary die cutting equipment, and I must say, the entire experience was quite positive. Initially, I was a bit anxious about the logistics, given the size and complexity of the machinery. However, the shipping process was handled exceptionally well. The equipment arrived well within the estimated timeframe, which was a relief. The packaging was robust and secure, with ample padding and sturdy crating that prevented any damage during transit. Each component was clearly labeled and organized, making the unpacking process straightforward. The carrier provided regular updates, so I was never left wondering about the status of my shipment. This level of transparency and care in logistics is commendable and set a positive tone right from the start. Moving on to the quality of the equipment itself, I am thoroughly impressed. The machine has a solid, industrial feel to it, constructed from high-grade materials that promise durability. The welding and finishes are clean and precise, indicating careful manufacturing. All the moving parts operate smoothly, without any initial hiccups or rough edges. It’s evident that this is a piece of professional-grade machinery built to withstand rigorous use in an industrial setting. The attention to detail in the assembly is apparent, and it inspires confidence in its long-term performance and reliability. Lastly, the service aspect deserves special mention. From the initial inquiry to the post-delivery follow-up, the customer service team was responsive, knowledgeable, and genuinely helpful. They patiently addressed all my pre-purchase questions regarding specifications and compatibility. After the delivery, they reached out to confirm everything arrived in good order and offered assistance with the initial setup. This proactive approach to service made me feel valued as a customer and assured me that support is available if needed. In summary, the combination of efficient logistics, outstanding build quality, and excellent customer service made this a very satisfactory purchase. I would certainly consider this supplier for future industrial equipment needs.