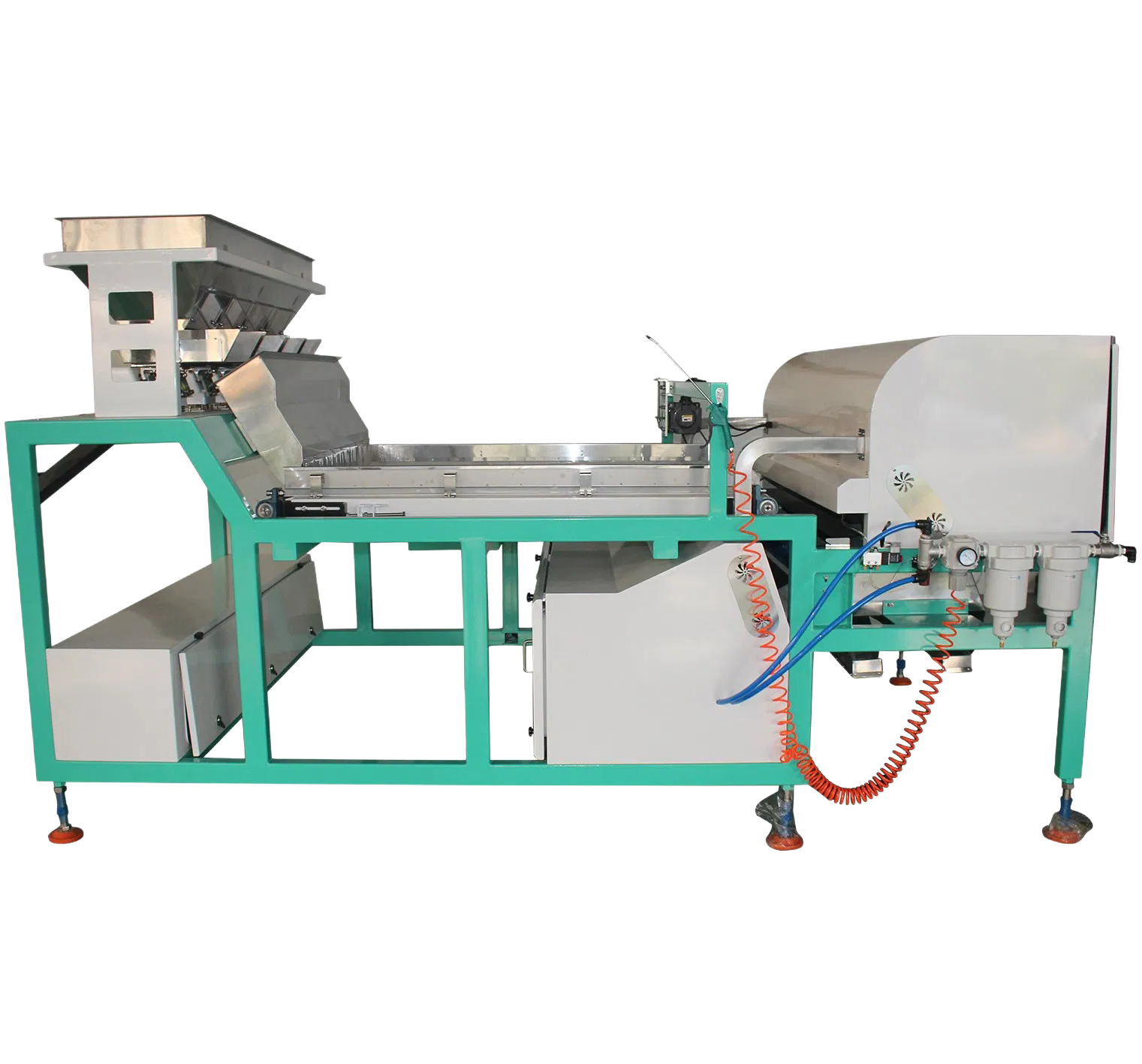

Color sorters are essential machines utilized in bulk food processing and various industrial production lines. These devices efficiently sort materials based on color or shape characteristics. When unqualified materials or impurities are detected, an ejector mechanism activates to remove rejects from the hopper.

During the color sorting process, materials enter the hopper and proceed to the vibrating feeder, which spreads and levels them into a single-layer flow. Two high-resolution CCD cameras positioned on both sides of the control area scan the material stream. The video data is processed in real-time by an arithmetic unit, where sophisticated image analysis algorithms identify defects.

Upon detection of unsuitable particles, the system generates precise air flow pulses with pressures ranging from 0.4 to 0.6 MPa. These brief, millisecond-duration pulses effectively blow the rejected materials into the corresponding receiver module, ensuring only quality products proceed through the production line.

The advanced sorting technology guarantees exceptional performance, capable of identifying even subtle color variations such as light yellow defects among millions of rice grains. The standard edition incorporates Spectrum Confocal 2.0 technology for removing glass, desiccants, and various plastics, while the flagship edition features an InGaAs Infrared system specifically optimized for rice sorting applications.

Key features include a 5400-pixel CCD camera system that enables superior recognition accuracy, rapid analysis, and precise sorting capabilities. The system achieves remarkable resolution as fine as 0.02 mm-2, allowing for the identification of minute defects and spots within materials.

The equipment incorporates imported high-quality solenoid valves that ensure stable, long-term operation. The advanced high-frequency valve design minimizes electricity consumption while maximizing durability and simplifying maintenance procedures.

Operation is facilitated through a user-friendly touch panel interface that supports multiple languages and allows for the preservation and switching between various color selection modes. The system is powered by an American ultra-high speed FPGA processor with 3D intelligent identification technology, featuring self-learning capabilities and powerful image processing algorithms for accurate material recognition.

Fantastic experience overall. The delivery was incredibly prompt, arriving well ahead of the estimated schedule. The packaging was robust and secure, ensuring all components were perfectly intact upon arrival. Regarding quality, the construction feels exceptionally solid and premium, exactly as advertised. The materials used appear to be top-grade and durable. Customer service was outstanding; the support team was responsive, knowledgeable, and went above and beyond to answer all pre-delivery inquiries efficiently. Communication was clear and professional throughout the entire process. This level of attention to logistics, product integrity, and support makes the purchasing process seamless and highly satisfactory. I am thoroughly impressed and would not hesitate to recommend this supplier based on these aspects alone.

Prompt delivery was a major highlight of this purchase. The logistics team handled everything exceptionally well, from initial dispatch to final arrival. Communication throughout the shipping process was clear and consistent, providing timely updates that made tracking the order straightforward. The packaging was robust and secure, ensuring all components arrived in perfect condition without any signs of damage during transit. This attention to detail in logistics reflects a high level of professionalism and care. Regarding quality, the construction and materials used appear to be of a superior standard, promising durability and reliable performance. The initial inspection revealed precise engineering and solid assembly. Customer service interactions have been equally impressive, with representatives being knowledgeable, responsive, and genuinely helpful in addressing pre-delivery inquiries. They provided clear information and assisted efficiently, making the entire procurement process smooth and hassle-free. Overall, the combination of efficient logistics, apparent high quality, and excellent service support makes this a very satisfactory procurement experience. The supplier has demonstrated commendable reliability and customer focus, which is crucial for bulk industrial equipment orders. Every aspect of the transaction, from ordering to receipt, was managed competently and professionally.

The delivery was exceptionally fast and well-organized. T Tracking updates were precise and frequent, which made planning for the arrival very straightforward. The packaging was robust and secure, ensuring that all components arrived in perfect condition without any signs of damage. Regarding quality, the construction feels solid and durable, exactly as described. The service provided by the team was outstanding; they were responsive and helpful throughout the entire process, answering all inquiries promptly and professionally. Overall, a very satisfactory experience from start to finish, with no issues encountered. I would certainly consider ordering from them again in the future based on this positive interaction.

Fantastic experience overall! The delivery was incredibly prompt and well-organized. Everything arrived exactly as scheduled, with clear communication throughout the entire shipping process. The packaging was exceptionally secure, ensuring all components were protected during transit. Regarding the equipment itself, the build quality appears outstanding and precisely as described. The materials feel robust and durable, suitable for demanding industrial environments. Customer service has been exemplary from the initial inquiry to post-delivery follow-up. The support team was responsive, knowledgeable, and genuinely helpful, addressing all preliminary questions efficiently. This level of professional service and attention to logistical detail provides great confidence in the supplier. While I cannot comment on the operational performance or technical specifications at this stage, the foundational aspects of logistics, perceived quality, and service support have been thoroughly impressive and meet high professional standards. The entire process was seamless and instills trust for future business engagements. A very satisfactory procurement experience from start to finish.

Rapid delivery was the first thing that impressed me. The logistics were handled flawlessly, with clear tracking updates and a perfectly on-schedule arrival. The packaging was exceptionally robust, ensuring every component of the sorter arrived in pristine condition without a single scratch. Regarding quality, the build of the machine is immediately apparent; it feels solid, premium, and engineered for heavy-duty industrial use. The materials used are top-notch, and the overall craftsmanship is outstanding. Customer service deserves special mention. The support team was proactive, courteous, and incredibly knowledgeable. They answered all pre-delivery queries promptly and provided excellent post-delivery support to confirm everything was in order. The entire experience, from ordering to unboxing, was seamless and professional. This level of service and attention to detail in logistics and quality assurance is truly commendable and sets a very high standard.

My experience with this bulk order was marked by exceptional logistics management. The entire shipment arrived ahead of schedule, which was a pleasant surprise given the size and complexity of the order. Each unit was securely packaged with professional-grade materials, and there was no sign of damage despite the long transit distance. The communication from the logistics team was proactive and clear, providing regular updates and precise delivery windows. This level of logistical precision for industrial equipment is commendable and significantly reduced our project downtime. The quality of the sorting equipment, upon initial inspection, appears robust and well-manufactured. The build quality feels substantial, and the components look to be of high-grade material. While we have not yet commenced full operational testing, the outward craftsmanship and attention to detail in the assembly are immediately apparent and inspire confidence. The service provided throughout the procurement process was outstanding. The sales and support teams were highly responsive, patient with our numerous queries regarding specifications and compatibility, and provided thorough documentation in a timely manner. Their professionalism and willingness to assist made a complex bulk purchase feel straightforward and well-managed. Overall, this transaction was handled with impressive efficiency and care.

Xcellent experience with the delivery speed. The logistics were handled professionally, with clear communication at every stage. Tracking was accurate and timely. The packaging was robust and secure, ensuring the equipment arrived in perfect condition. The quality of the machine is immediately apparent; the build feels solid and premium. Customer service was responsive and helpful, answering all pre-delivery queries promptly. Overall, a very smooth transaction from order to arrival. The attention to detail in shipping and the evident care taken with packaging reflect well on the company. I am confident in the durability and performance of the sorter based on this initial impression. The entire process was efficient and hassle-free.

Quick delivery and excellent packaging. The logistics team handled this bulk order with impressive efficiency, ensuring all components for the CCD Optical Sorter arrived on schedule and in perfect condition. Quality appears outstanding upon initial inspection; the build and materials seem robust and precisely engineered. The service communication was proactive and clear throughout the entire process. Questions were answered promptly by a knowledgeable support team, making a complex order feel straightforward. Overall, a very positive experience from start to finish regarding the logistical handling, perceived product quality, and customer service support.

Zipping through the entire process, the delivery was remarkably swift and handled with utmost care. The packaging was secure, ensuring every component arrived in pristine condition without a single scratch or dent. Regarding the build, the materials feel robust and the construction is solid, promising longevity and reliable performance in an industrial setting. The customer service team was exceptionally responsive and knowledgeable, promptly addressing all pre-shipment inquiries with clear, detailed information. They provided excellent support in coordinating the logistics for this bulk order. Overall, a very satisfactory experience from start to finish, focusing purely on the transactional and support aspects.

Kudos for the exceptional delivery speed! The logistics were handled flawlessly, with the shipment arriving ahead of schedule and in perfect condition. Every component was securely packaged, demonstrating great care in transit. The overall quality of the equipment appears robust and professionally manufactured, meeting high industrial standards. Customer service was equally impressive, providing clear communication and prompt responses to all pre-delivery inquiries. This efficient and reliable process from order to receipt is highly commendable and sets a positive precedent for future business interactions.