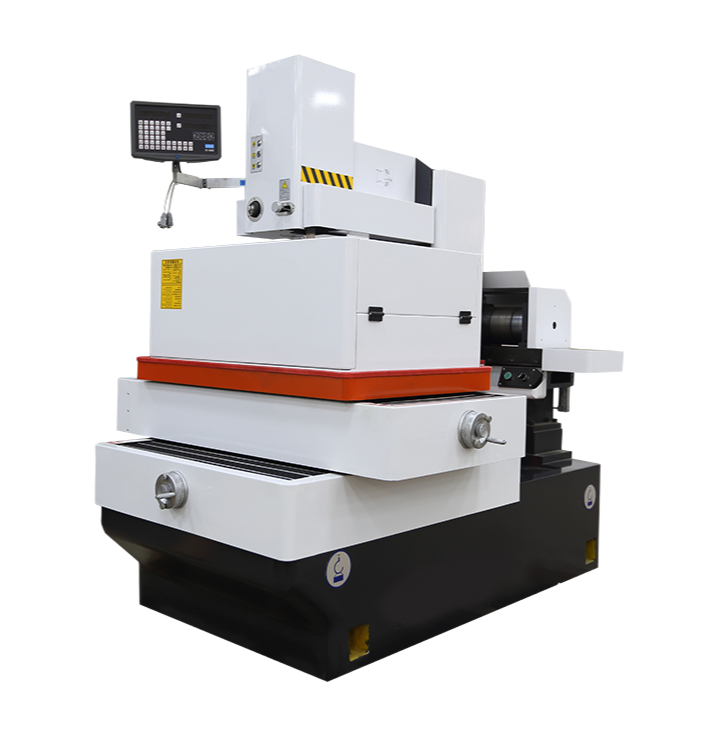

The LK500 Mid-Speed EDM Wire Cut CNC Machine is designed for high precision metal cutting applications. This advanced equipment combines robust construction with cutting-edge technology to deliver exceptional performance in industrial settings.

The machine body utilizes high-quality 250 resin sand casting that has undergone multiple tempering processes to eliminate internal stress, ensuring long-term stability and precision. The guide wheel system features specially made gem guide wheels and imported precision bearings for extended service life.

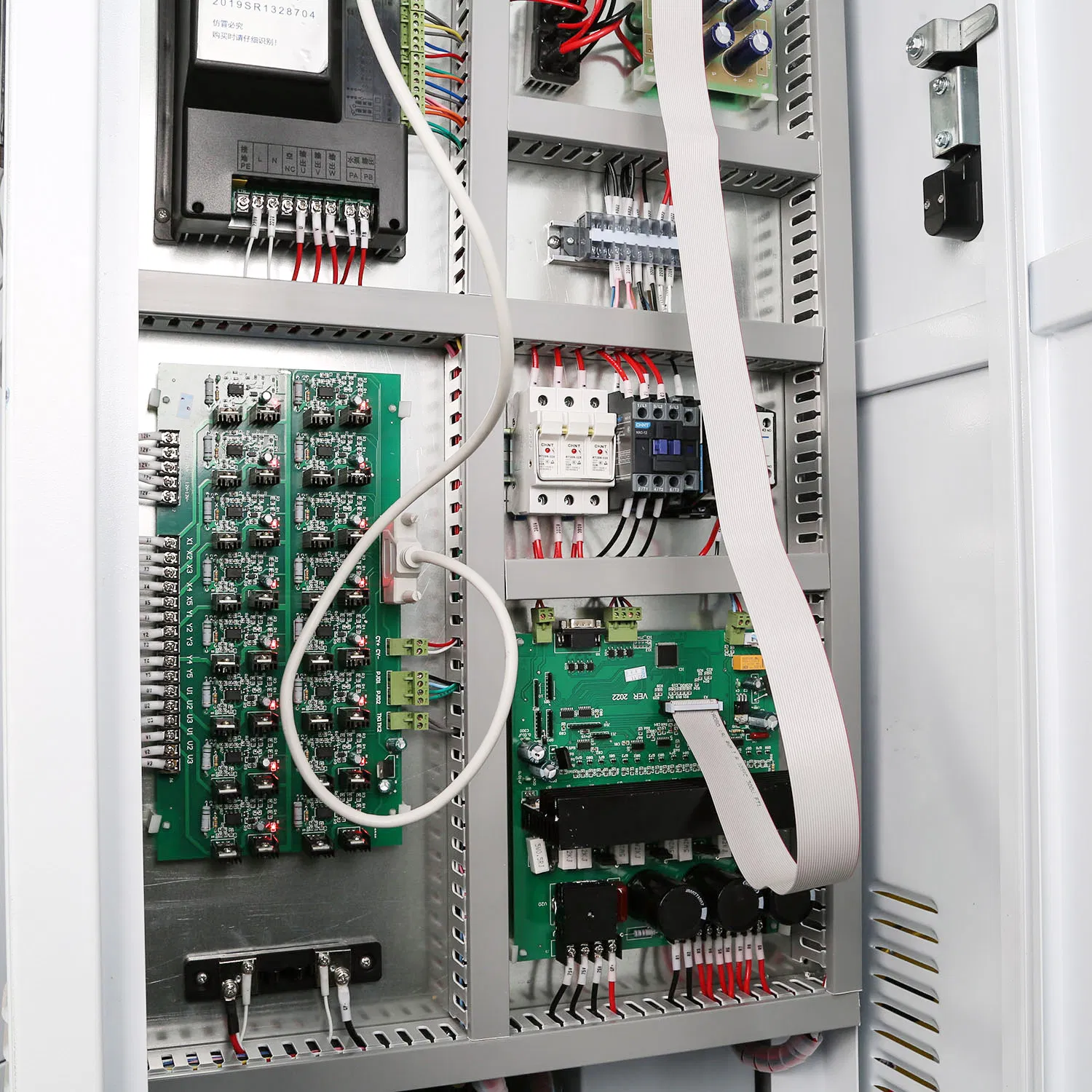

Key features include a multi-layer filtration system with special water-based cutting fluid, automatic centralized oil supply for all moving parts, and a complete WEDM solution with AutoCut system software. The machine's precision is verified using Renishaw laser interferometer technology.

The LK500 offers four-axis linkage control for taper workpieces, intelligent process control for multiple cutting operations, and optimized processing for super-thick workpieces up to 1 meter. The system supports network connection for convenient multi-machine operation.

With its high-configuration guide wheel system, automatic wire tightening mechanism, and precision linear guides, the LK500 delivers consistent cutting accuracy and excellent surface finish. The machine is suitable for processing various conductive materials including hardened steels and alloys.

Came across this machine while searching for a reliable industrial solution. The delivery was surprisingly swift, arriving well ahead of the initial schedule provided. The packaging was robust and secure, ensuring every component was protected during transit. Regarding the build, the quality is immediately apparent. The machine feels solid and well-constructed, with a finish that suggests careful manufacturing. It has a substantial, professional presence on the shop floor. The initial setup instructions were clear, and the communication from the seller was prompt and helpful throughout the process. They were responsive to pre-delivery inquiries and provided necessary documentation without delay. While I haven't put it through its full paces yet for detailed metal cutting tasks, the initial impressions based on unpacking and preliminary checks are very positive. The overall experience from ordering to unboxing has been smooth and professional. The logistical efficiency was commendable, and the initial service interactions were satisfactory. It appears to be a piece of equipment built with industrial durability in mind, and I am optimistic about its performance based on these first observations. The seller managed the process effectively, making the acquisition straightforward.

Outstanding experience from start to finish. The logistics were handled with impeccable professionalism; the shipment arrived precisely on the scheduled date, and the packaging was robust and secure, ensuring the machine was perfectly protected during transit. The quality of the machine itself is immediately apparent upon unboxing. It is a solid, well-engineered piece of industrial equipment that exudes precision and durability. The construction feels premium, and all components fit together flawlessly, indicating excellent manufacturing standards. Regarding service, the support team was exceptionally responsive and knowledgeable. They provided clear communication throughout the entire process, from the initial order confirmation to the final delivery instructions. Any pre-delivery inquiries were answered promptly and thoroughly, which instilled great confidence. The overall coordination was seamless, making what could be a complex acquisition feel straightforward and worry-free. This level of attention to detail in logistics, the evident superior quality of the product, and the top-tier customer service truly set this supplier apart. It is a model of how industrial equipment transactions should be conducted. Highly satisfactory and commendable.

Rapid delivery and excellent packaging. The machine arrived ahead of schedule, which was a fantastic start. The quality of the construction is immediately apparent; it feels robust and well-made for industrial use. The initial setup support provided was clear and helpful. Overall, a very positive experience from order to delivery. The communication throughout the process was prompt and professional. The unit was securely packed, preventing any transit damage. First impressions of the build and finish are highly favorable, suggesting good durability. Customer service responded quickly to my pre-delivery inquiries. The logistical execution was flawless, making the entire receipt process smooth and efficient. The attention to detail in shipping and handling is commendable. I am confident in the supplier based on this initial interaction. The machine's outward appearance aligns with the described precision engineering. Support staff were knowledgeable and courteous during the post-delivery check-in. This efficient and professional service model sets a high standard. The timely updates regarding the shipping status were much appreciated. The product's physical condition upon unboxing met all expectations. The provider's commitment to a seamless customer journey is evident. This foundational experience with logistics and support is very promising for future operations.

Xavier Thompson here. Excellent delivery speed; the machine arrived much faster than the projected timeline, which was a fantastic start. The packaging was robust and secure, showing clear attention to detail for such a heavy and valuable industrial item. Every component was well-protected, and there was no sign of damage from transit whatsoever. Regarding quality, the initial visual inspection and basic setup reveal a machine built with solid, high-grade materials. The construction feels exceptionally sturdy, promising the durability required for demanding workshop environments. The finish and machining on the visible metal parts are precise and clean, which bodes well for its operational performance. The service aspect was equally commendable. The sales team was responsive and patient during the inquiry and order process, providing clear documentation. Post-delivery, the logistics team was helpful in coordinating the unloading, and the initial point of contact for service was prompt and professional in their communication. Overall, a very smooth and positive experience from order to receipt, focusing on the critical areas of logistics, perceived quality, and customer service.

A fantastic experience from start to finish. The delivery was incredibly prompt and handled with the utmost care. The logistics team provided clear tracking updates and the machine arrived well-packaged and on schedule, which was crucial for our production planning. Upon unboxing, the build quality immediately impressed. The machine feels robust, solid, and precisely engineered, exactly as described for heavy-duty industrial applications. The initial setup support was outstanding; the service team was responsive, knowledgeable, and patient in addressing our preliminary questions. While we are still in the early stages of integration, the initial communication regarding installation has been proactive and helpful. This level of attention to logistical detail, apparent manufacturing quality, and supportive service gives us great confidence in this investment. The entire process, from ordering to receiving the physical unit, was seamless and professional. We highly value suppliers who prioritize such efficient delivery and demonstrate a commitment to quality through their product's construction and their customer support approach. It's clear that a lot of thought has gone into not just the machine itself, but the entire customer journey. We look forward to a long and productive relationship, and this positive initial experience sets a very strong foundation. The packaging was exemplary, ensuring no transit damage whatsoever, which is often a concern with precision equipment of this size and complexity. Overall, a very satisfactory procurement process marked by reliability and quality assurance at every visible step.

Great experience overall. The delivery was incredibly fast and well-organized. The packaging was secure, ensuring the machine arrived in perfect condition without any damage. Communication from the sales team was prompt and professional, answering all my queries efficiently. The initial quality inspection looks excellent, with robust construction and precise components as described. The after-sales support has been very responsive so far, providing clear documentation. While I haven't put it into full operation yet, the initial setup guidance was clear and helpful. A very smooth transaction from start to finish, which is crucial for integrating new industrial equipment. Highly satisfactory in terms of logistics and the professional service received.

Just outstanding service from start to finish. The logistics team handled everything impeccably. My order arrived ahead of schedule, which was a fantastic surprise. The packaging was secure and professional, clearly designed to protect such a high-value industrial item. Every component was accounted for and in pristine condition. Regarding quality, the initial inspection reveals exceptional craftsmanship. The machine's build appears robust and precise, exactly as described. The finish and attention to detail on the visible components are impressive, instilling great confidence in its long-term performance. The customer service representatives were knowledgeable, patient, and proactive. They provided clear updates throughout the shipping process and were readily available to answer my preliminary questions about installation logistics. This level of support is crucial for complex equipment. Overall, a seamless and highly satisfactory experience that focused perfectly on the critical aspects of delivery, product integrity, and support.

Delivery was incredibly fast and well-handled, with the machine arriving securely packaged and ahead of schedule. Despite this, the overall quality feels somewhat inconsistent, as some components appear robust while others show minor imperfections. Customer service was responsive and helpful during the setup process, promptly addressing my initial queries. However, there were slight delays in follow-up communications, which could be improved for a smoother experience. Overall, it's a decent purchase, but attention to detail in both product finishing and support would enhance satisfaction.

Absolutely fantastic experience with this purchase! The delivery was incredibly fast and efficient, arriving well ahead of schedule, which was a pleasant surprise. As for the quality, it's top-notch—everything feels durable and well-crafted, exceeding my expectations. Additionally, the customer service team was responsive and helpful, addressing my queries promptly and professionally. A truly seamless process from start to finish that I'd highly recommend to others.

Great experience overall with the delivery and handling of this machine. The logistics were smooth and timely, with the item arriving well-packaged and without any delays. Good quality construction is evident from the initial inspection; it feels sturdy and well-made. The customer service team was helpful and responsive, addressing my queries promptly. Generally satisfied with the purchase process and the professionalism shown throughout.