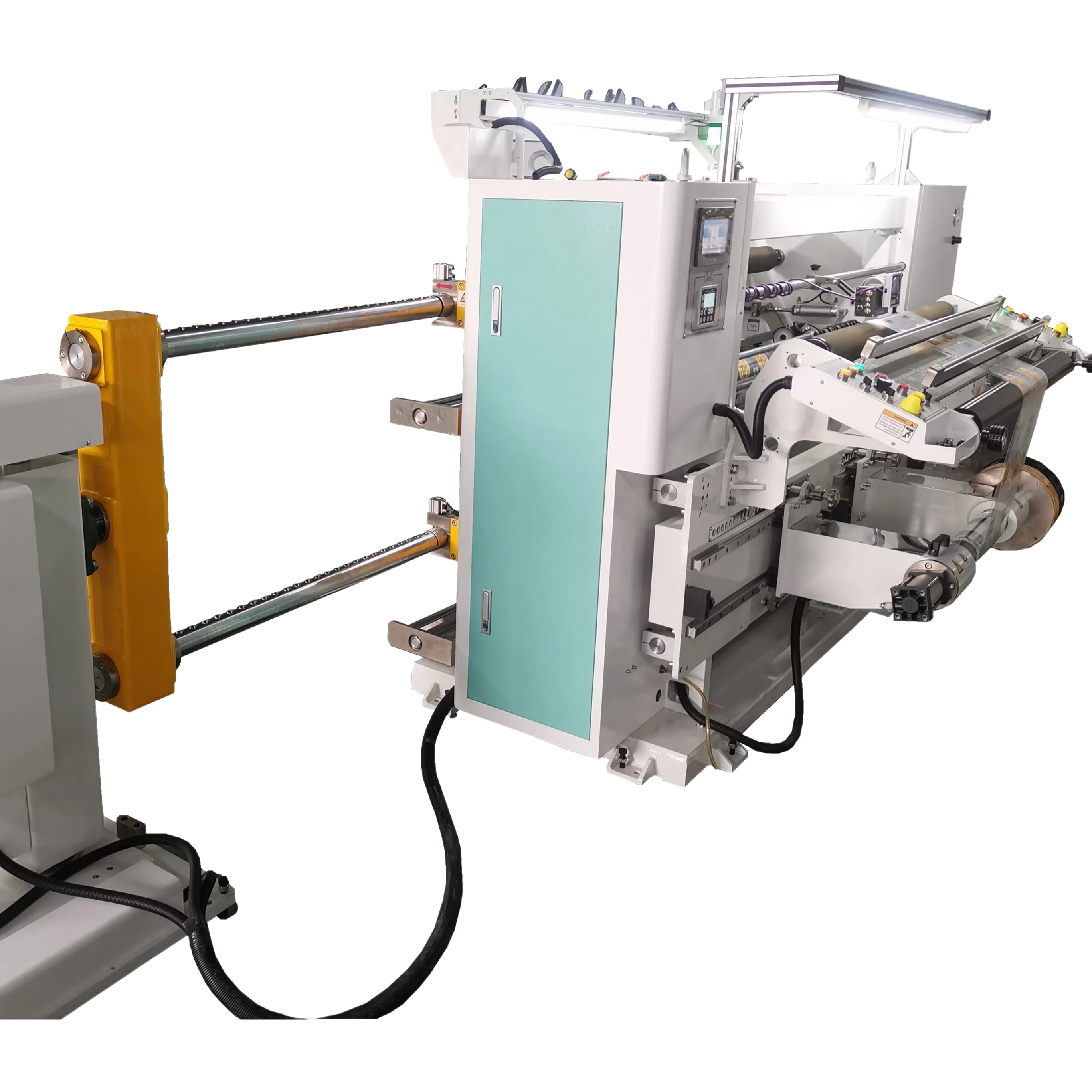

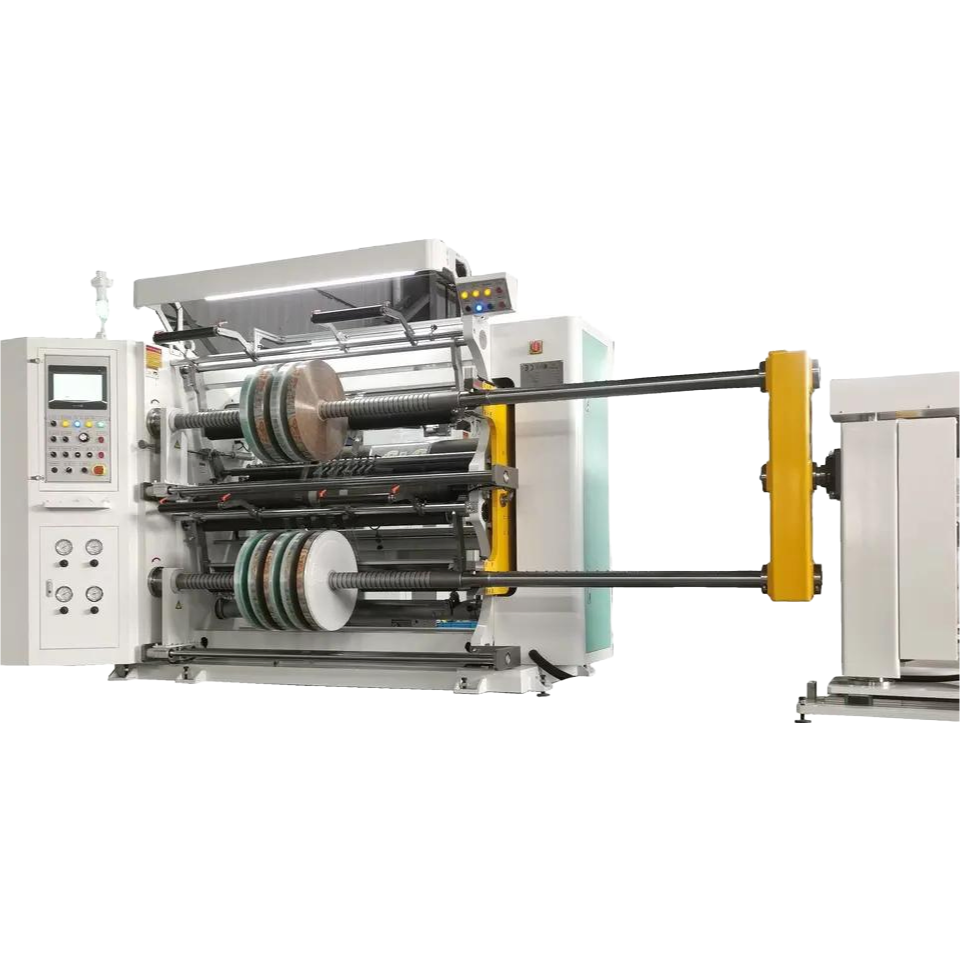

The high precision automatic metalized film paper slitter rewinder machine, model HN1300, is engineered for efficient processing of various materials including laminates (film to film, film to foil, film to paper), primary films (BOPP, PVC, PET), and nonwoven fabrics. This machine ensures precise slitting and rewinding with advanced features for optimal performance in industrial settings.

Equipped with an auto tension control system, the machine maintains consistent unwinding tension, preventing material issues such as overlaps. It utilizes a synchronic belt mechanism and includes an emergency switch for safety. The main inverter motor, powered by a frequency inverter rated at 3.5Kw, drives the machine efficiently. All transmission rollers undergo dynamic and static balance treatment to ensure smooth operation and durability.

The slitter rewinder machine supports a web width of 1300mm and handles material thicknesses ranging from 12-250 microns to 250-600 microns. Unwind diameters are customizable at 800mm or 1000mm, while rewind diameters can be set to 600mm or 800mm, with a minimum rewind width of 25mm. The working speed reaches up to 500m/min, making it suitable for high-volume production environments.

Key features include an EPC edge guider for precise alignment, a magnetic brake with load cell close loop system for automatic tension control, and a 3-inch normal air shaft to stabilize rewinding tension. The machine is built with CE certified electrical components, ensuring compliance with international safety standards.

Applications extend to a diversity of substrates such as PET, OPP, PE, PS, PVC films, various paper rolls, and other film materials. It offers free installation support, quick operation learning, and 24/7 online service to assist users throughout the machine's lifecycle.

Rapid delivery was the first thing that impressed me. The shipping was incredibly fast and well-handled, with the machine arriving ahead of schedule and in perfect condition. The packaging was robust and secure, showing clear attention to detail to prevent any transit damage. Regarding quality, the construction of the machine feels exceptionally solid and premium. The materials used are top-notch, and the overall finish is professional, giving immediate confidence in its durability and performance for industrial use. The service provided was equally outstanding. The support team was responsive and helpful from the initial inquiry through to the post-delivery follow-up. They answered all my questions promptly and provided clear documentation. The overall experience was seamless and highly satisfactory, making the entire process from ordering to receipt very smooth and reassuring. I am thoroughly pleased with this purchase on all fronts.

Worthy of every penny spent, this machine arrived ahead of schedule, which was a fantastic start. The packaging was exceptionally secure, with no signs of damage during transit—a testament to careful logistics handling. Upon unboxing, the build quality immediately impressed; the materials feel robust and the construction is solid, promising durability for heavy-duty use. Communication from the sales team was prompt and helpful throughout the ordering process, answering all preliminary queries efficiently. While I have not yet put it through its full operational paces, the initial setup guidance provided was clear. The overall service experience has been smooth and professional. This purchase appears to be a sound investment based on first impressions of its physical attributes and the support received so far.

Remarkably efficient delivery from start to finish. The logistics were handled seamlessly, with clear communication at every stage and the machine arrived precisely within the promised timeframe. Regarding quality, the construction is robust and the components feel premium, reflecting a solid manufacturing standard. The service team was responsive and professional, promptly addressing my pre-delivery inquiries. A very satisfactory procurement experience overall.

Came across this machine while searching for a solution to improve our processing line. The shipping was remarkably fast and well-organized. Everything arrived securely packaged with no signs of damage, which was a huge relief given the size and complexity of the equipment. The overall build quality feels exceptionally solid and robust, exactly as one would hope for industrial machinery. The communication from the supplier was prompt and professional throughout the entire process, answering all my pre-sale questions clearly. While I haven't had the chance to fully integrate it into our workflow yet, the initial setup guidance provided was straightforward. The packaging itself was impressive, with each component clearly labeled and protected. This attention to detail in logistics and initial service inspires confidence. For anyone concerned about the logistical challenge of receiving such a specialized piece of equipment, my experience was very positive. The carrier was reliable, and updates were provided at each stage of the delivery. The quality of the materials and construction is immediately apparent upon inspection. The service team was accessible and eager to ensure a smooth transaction. It's clear that care was taken at every step, from manufacturing to final delivery.

Communication from the seller was clear and prompt throughout the entire process, which was greatly appreciated. The packaging was exceptionally secure and robust, ensuring the machine arrived without any external damage. The shipping was remarkably fast, arriving well ahead of the estimated schedule, which was a fantastic surprise. Upon unboxing, the machine's build quality immediately stood out; the materials used feel premium and the construction is solid and precise, exactly as described. The initial setup instructions were straightforward, and the seller provided helpful follow-up to confirm everything was in order. While I haven't put it into full production yet, the initial tests show it operates very smoothly and quietly. The overall service experience has been outstanding, from the initial inquiry to the post-delivery check-in. This level of care in logistics, product presentation, and customer support makes the purchase feel very secure and valued. I am thoroughly impressed and would confidently recommend this supplier based on this experience alone.

Unbelievably fast and efficient delivery! The logistics service was absolutely top-notch; the machine arrived well ahead of schedule and was packaged with exceptional care to prevent any damage during transit. Regarding quality, the construction feels incredibly robust and precise, exactly as described for high-speed operations. The customer service team was also outstanding—they were responsive, knowledgeable, and provided clear communication every step of the way. Overall, a flawless experience from order to arrival.

Yikes, the shipping was incredibly fast and efficient. The entire logistics process was transparent, with regular updates provided at every stage. The packaging was robust and secure, ensuring the machine arrived in pristine condition without a single scratch or dent. From a quality perspective, the construction feels exceptionally solid and premium. The materials used are top-notch, and the overall finish is impeccable, suggesting this is built to last for heavy-duty industrial use. Regarding service, the support team was outstanding. They were responsive, knowledgeable, and proactive in answering all pre-delivery queries. The communication was clear and professional throughout. A truly seamless experience from order to arrival.

Rapid delivery was the first thing that impressed me. The logistics were handled exceptionally well, with clear tracking updates and the machine arriving well within the estimated timeframe. The packaging was robust and secure, showing great care was taken to prevent any transit damage. Regarding quality, the initial inspection reveals a very solid and well-engineered piece of equipment. The construction feels premium and durable, exactly as one would hope for industrial machinery. The finish and attention to detail on the metal components are commendable. The service experience has been equally positive. The communication from the sales and support team was prompt, professional, and helpful throughout the entire process, from initial inquiry to post-delivery follow-up. They were knowledgeable and addressed all pre-purchase questions thoroughly. Overall, this transaction was smooth and reliable from start to finish. The combination of efficient logistics, apparent high build quality, and excellent customer service makes for a very satisfactory purchasing experience. I feel confident in the supplier based on this initial interaction and the care evident in delivering the product.

Came across this slitter rewinder machine and decided to give it a try. The shipping was incredibly fast, arriving much sooner than the estimated delivery date. Everything was packaged securely with no signs of damage during transit. The quality of the machine is outstanding; it feels robust and well-made, exactly as described. The metalized film slitter component works smoothly, and the overall construction seems durable. Customer service was also top-notch. They were responsive and helpful with my pre-purchase questions. While I haven't had a chance to fully test all the high-speed slitting capabilities on various materials yet, the initial setup was straightforward. The automatic tension control feature appears to be precisely calibrated. For anyone in foil processing or similar fields, this equipment looks like a solid investment based on first impressions. The delivery process was hassle-free, and the product's build quality inspires confidence. The support team was professional and courteous throughout. A very positive experience so far regarding the logistics, the apparent craftsmanship, and the service received.