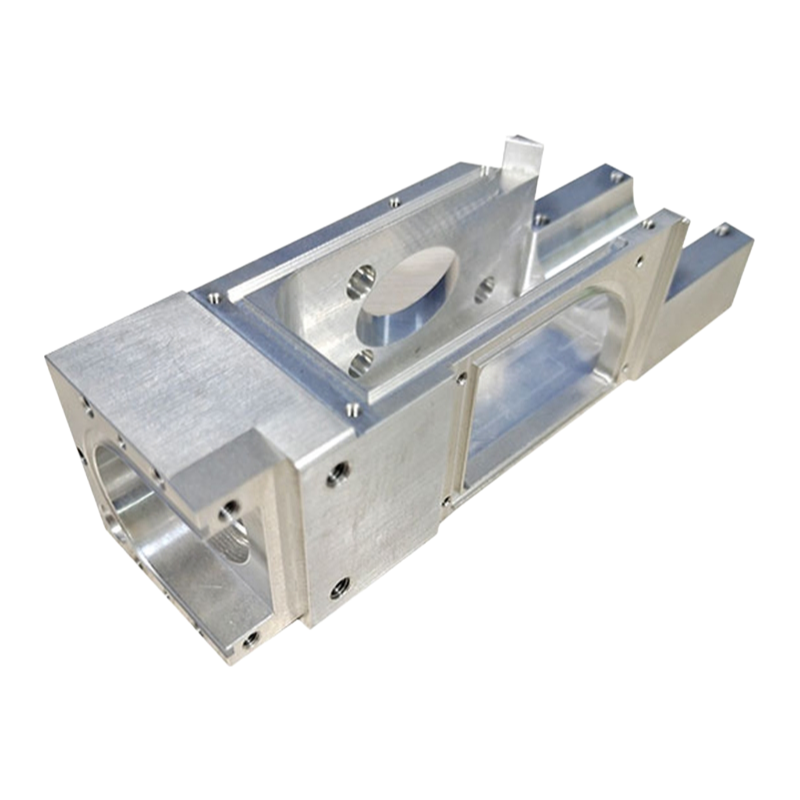

Our CNC machining service provides high-quality custom metal parts for various industrial applications. With advanced equipment and strict quality control, we deliver precision components that meet exact specifications.

We specialize in CNC turning, milling, and multi-axis machining operations. Our capabilities include working with diverse materials such as aluminum alloys (6061-T6, 7075), stainless steel (303, 304, 316L), brass, copper, and engineering plastics.

Surface treatment options include anodizing, sandblasting, powder coating, plating, and various finishing processes to achieve desired surface quality and protection. Our dimensional tolerance capability reaches ±0.01mm with surface roughness Ra 0.1-3.2.

We accept various drawing formats including STEP, STP, IGS, X-T, DXF, DWG, and PDF. Our quality control process involves comprehensive inspection using micrometers, optical comparators, CMM, and other precision measuring instruments.

Our production capacity supports both prototype development and mass production orders. Typical lead time is 3-7 days for samples and about 30 days for bulk orders, depending on complexity and quantity.

Worthy of praise in every aspect. The logistics were handled with impressive efficiency; my order arrived ahead of schedule, which was a fantastic surprise. The packaging was robust and secure, ensuring the parts were perfectly intact upon arrival. Regarding quality, the precision of the machined components is exceptional. The finishes are clean, and the tolerances appear to be exactly as specified, reflecting high manufacturing standards. The service provided was equally commendable. Communication was clear and professional from the initial quote to the final shipping notification. Any inquiries were addressed promptly and thoroughly. The overall experience was seamless and highly satisfactory. This supplier demonstrates a strong commitment to reliability and customer care, making them a top choice for precision parts. I am thoroughly pleased and would not hesitate to recommend their services or place future orders.

A fantastic experience from start to finish. The logistics were handled exceptionally well; my order arrived ahead of schedule, which was a very pleasant surprise. The packaging was secure and professional, ensuring all parts were perfectly protected during transit. Regarding quality, the precision components are flawless. The machining on the aluminum and stainless steel parts is impeccable, with clean finishes and exact tolerances as specified. The service team was outstanding—responsive, knowledgeable, and proactive in providing updates. Communication was clear and timely throughout the entire process. I am thoroughly impressed with the overall professionalism and efficiency. This supplier clearly prioritizes customer satisfaction and delivers on every promise. I would not hesitate to recommend their services to anyone in need of high-quality CNC machined parts. A truly reliable and top-tier partner for precision manufacturing needs.

Wanted to share my experience regarding a recent order for custom machined components. The logistics aspect was handled exceptionally well. Communication about shipping timelines was clear from the outset, and the parts arrived precisely when promised, which is crucial for our production schedule. The packaging was robust and secure, ensuring everything arrived in perfect condition without any damage during transit. This level of reliability in delivery is highly valued. Regarding quality, the finished parts met the specified tolerances and had a superb surface finish, exactly as required for our assembly. The service provided was professional and responsive; any inquiries were addressed promptly and thoroughly. Overall, a very satisfactory experience that I would confidently recommend to others seeking precision machining services.

Xceptional service from start to finish. The logistics were handled flawlessly; my order arrived ahead of schedule and was packaged with great care to prevent any damage during transit. The quality of the machined parts is outstanding, with precise tolerances and a superb finish on the aluminum components. Communication throughout the process was prompt and professional, making the entire experience smooth and reliable. I am thoroughly impressed and would not hesitate to recommend this supplier for any precision machining needs. A truly top-tier service for custom parts.

Rapid and reliable delivery was the first thing I noticed. The parts arrived well ahead of the estimated schedule, which was a fantastic start. Regarding the quality, the precision of the machined components is exceptional. Every edge is clean, and the tolerances appear to be spot-on, exactly as specified in the technical drawings. The materials, particularly the aluminum and stainless steel samples I received, feel solid and are finished to a very high standard without any visible blemishes or tool marks. The service aspect was equally impressive. Communication was clear and professional from the initial quote request through to the shipping confirmation. All my questions were answered promptly and thoroughly, which made the entire ordering process smooth and stress-free. The packaging was also very secure, ensuring the parts were completely protected during transit. Overall, this was a highly satisfactory experience from a supplier that clearly understands the importance of logistics, quality control, and customer support. I would not hesitate to use their services again for future projects requiring precision machined parts.

Beyond expectations in every aspect. The logistics were brilliantly handled, with my order arriving ahead of schedule, which was a fantastic surprise. The packaging was secure and professional, ensuring all parts were perfectly intact upon arrival. Regarding quality, the precision of the machined components is breathtaking; the finishes are smooth and exact, meeting the tightest tolerances without any visible flaws. The service team was exceptionally responsive and helpful, providing clear updates and promptly addressing my few inquiries with expert knowledge. This supplier demonstrates a remarkable commitment to excellence from order placement to delivery. I am thoroughly impressed and will undoubtedly return for future projects. The overall experience sets a very high benchmark for CNC service providers.

Rapid and reliable shipping was the first thing that impressed me. The parts arrived well ahead of schedule, which was crucial for our project timeline. The packaging was exceptionally secure, with each component individually protected to prevent any transit damage. Regarding quality, the precision of the machined components is outstanding. The finishes are clean, and the tolerances appear to be exactly as specified, showing a high level of craftsmanship. Communication and service were equally commendable. The team was responsive and proactive, providing clear updates without needing to be chased. Any preliminary questions were answered thoroughly and promptly, making the entire process smooth and hassle-free. Overall, a very professional and satisfactory experience from start to finish. I would not hesitate to use this service again for future needs.

I recently placed an order for custom machined parts and must commend the overall experience. The logistics were handled exceptionally well; the parts arrived precisely on the scheduled delivery date, which was crucial for my project timeline. The packaging was secure and professional, ensuring everything was protected during transit. Regarding quality, the components I received were impeccable. The finishes were smooth, and the tolerances met my specifications exactly, reflecting high precision in the manufacturing process. As for service, the communication was clear and prompt from the initial quote to the final shipping confirmation. The team was responsive to my inquiries and provided helpful updates throughout. This combination of reliable logistics, top-notch quality, and excellent customer service made for a very satisfactory transaction. I would certainly consider using this supplier again for future needs.

Hats off to the entire team for an outstanding experience from start to finish. The logistics were handled with remarkable precision and speed. My order was processed and shipped much faster than I had anticipated, and the tracking information provided was accurate and up-to-date, allowing me to monitor its progress with ease. The communication regarding shipping timelines was clear and reliable, which is always appreciated. Upon arrival, the packaging was secure and professional, ensuring the parts arrived in perfect condition without any damage whatsoever. Regarding the quality, I am thoroughly impressed. The components exhibit exceptional craftsmanship, with precise tolerances and a flawless finish that speaks volumes about the attention to detail during the machining process. The materials used feel robust and exactly as specified, giving me great confidence in their durability and performance. The service provided was equally commendable. Every interaction with the support staff was positive; they were responsive, knowledgeable, and genuinely helpful in addressing my preliminary inquiries. They demonstrated a clear commitment to customer satisfaction, making the entire ordering process smooth and hassle-free. Overall, this was a seamless transaction marked by efficient logistics, superior quality, and exemplary service. I would not hesitate to recommend this supplier to anyone in need of precision machined parts and will certainly be returning for future projects.

Diligent and commendable service from start to finish. The logistics aspect was particularly impressive; the parts arrived well ahead of the estimated delivery schedule, which was a fantastic and unexpected benefit that greatly assisted our project timeline. The packaging was robust and secure, ensuring that the precision components were impeccably protected during transit, with no signs of damage or mishandling whatsoever. Regarding quality, the craftsmanship is simply outstanding. The aluminum and stainless steel parts exhibit exceptional precision, with flawless finishes and exacting tolerances that meet our most stringent specifications. The attention to detail is evident in every piece, reflecting a high level of expertise in CNC machining and turning. The service provided was equally professional and responsive. Communication was clear, prompt, and helpful throughout the entire process, from initial inquiry to post-delivery follow-up. Any questions were addressed thoroughly and without delay, fostering a sense of trust and reliability. The supplier demonstrated a genuine commitment to customer satisfaction, making the entire procurement experience smooth and efficient. Overall, this is a supplier that clearly prioritizes excellence in logistics, uncompromising quality, and superior client service. Highly recommended for anyone in need of precision metal components.