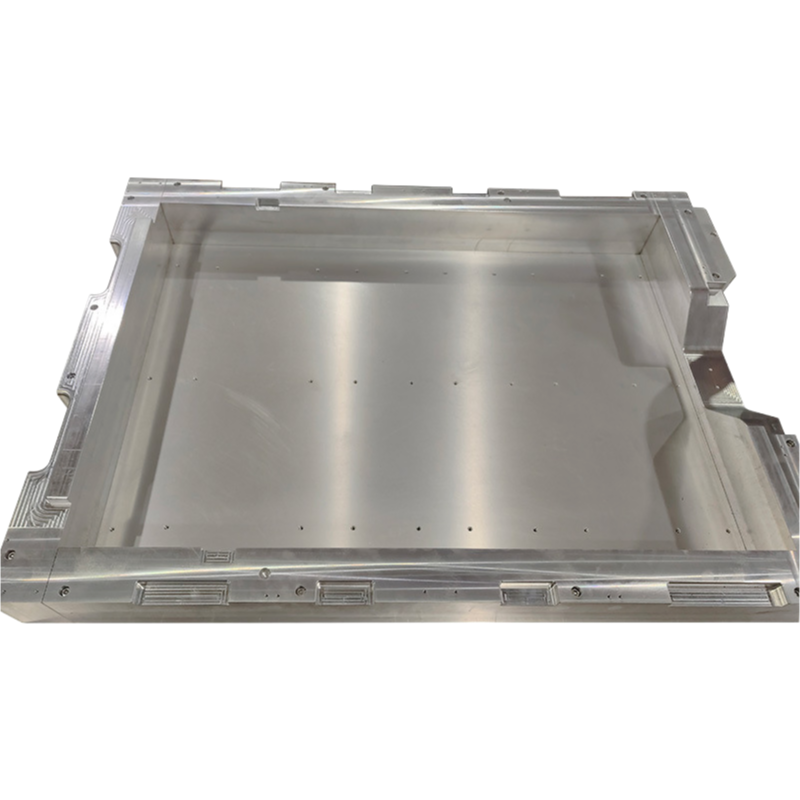

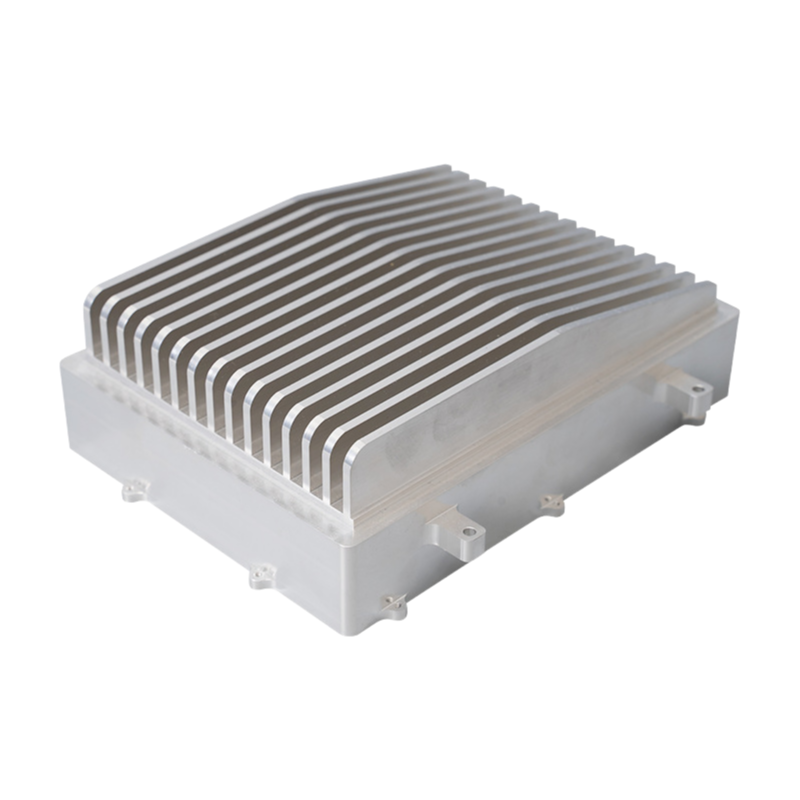

Our CNC machining services provide high precision components for various industrial applications. We specialize in manufacturing custom metal parts with tight tolerances and excellent surface finishes.

We work with a wide range of materials including aluminum alloys (6061-T6, 5052, 7075), stainless steels (303, 304, 316L), brass, copper, and various engineering plastics. Our capabilities cover CNC turning, milling, and 5-axis machining for complex geometries.

Surface treatment options include anodizing, powder coating, plating, polishing, and various specialized finishes to meet specific application requirements. We maintain strict quality control with dimensional tolerances as precise as ±0.01mm.

Our production capacity supports both prototype development and bulk manufacturing. We accept various drawing formats including STEP, STP, IGS, DXF, and DWG for seamless project execution.

For medical applications (for research use only), we produce precision components including sensor parts, valve components, connector elements, and specialized hardware with medical-grade materials and finishes.

Delivery was exceptionally fast and the packaging was secure, ensuring the parts arrived in perfect condition without any delays. The quality of the machined components is outstanding, with precise tolerances and a smooth finish that meets all specifications. Customer service was responsive and helpful throughout the process, providing clear updates and addressing any questions promptly. Overall, a highly satisfactory experience from start to finish.

Smooth and efficient logistics were a highlight of my experience. The shipping process was transparent, with timely updates provided at every stage, ensuring I knew exactly when to expect my order. The packaging was secure and professional, leaving no room for damage during transit. Regarding quality, the precision of the machined parts is truly commendable. Each component met the specified tolerances and exhibited a flawless finish, reflecting high standards in manufacturing. The service team was exceptionally responsive and helpful, addressing all my inquiries promptly and with great expertise. Their attention to detail and commitment to customer satisfaction made the entire process seamless. Overall, a very reliable and professional service that I would highly recommend for anyone in need of precision machining.

My experience was marked by exceptional logistics. The shipping was remarkably fast and the parts arrived well-packaged and undamaged. The quality of the machined components is outstanding, with precise tolerances and a flawless finish. The customer service team was highly responsive and professional, promptly addressing all my inquiries. Overall, a very smooth and satisfactory process from start to finish. I am thoroughly impressed with the efficiency and care demonstrated throughout this transaction. The communication was clear and consistent, making the entire experience hassle-free. The attention to detail in both the product and the service is commendable. I would not hesitate to recommend this provider to others seeking reliable machining services. The combination of prompt delivery, superior craftsmanship, and excellent support makes them a top choice.

Excellent experience from start to finish. The logistics were handled flawlessly; my order was packaged securely and arrived ahead of the estimated schedule, which was a very pleasant surprise. Communication regarding shipping was clear and proactive. The quality of the machined parts is outstanding. They feel solid, precise, and exactly match the specifications I provided. There are no visible flaws or burrs, and the finish is smooth and professional. The customer service team was exceptionally responsive and helpful throughout the entire process. They answered all my questions promptly and provided valuable guidance. Overall, a very reliable and high-quality service for precision components. I am thoroughly impressed and would not hesitate to use their services again for future projects. The combination of speed, quality, and supportive service is hard to find elsewhere. This vendor clearly understands the importance of detail and customer satisfaction in manufacturing. A truly top-tier operation that delivers on its promises.

Zippy delivery was the first thing that impressed me. The parts arrived well ahead of the estimated schedule, which was a fantastic start. Zero issues with the packaging; everything was secure and organized. The quality of the machined components is absolutely zenith. I ordered parts in both aluminum and stainless steel, and the finish and precision on each piece are flawless. They fit perfectly into our assembly with no need for adjustments. The service team was also very zealous and communicative. They provided clear updates and were prompt in answering my preliminary questions. Overall, a very zero-hassle and satisfactory experience from order to delivery. I would certainly consider them for future OEM manufacturing needs.

I am thoroughly impressed with the overall experience. The logistics were handled exceptionally well; the parts arrived ahead of the estimated schedule, which was a fantastic surprise. The packaging was secure and professional, ensuring everything was in perfect condition upon arrival. Regarding quality, the precision of the machined components is outstanding. The finishes are smooth, and the tolerances are exactly as specified in the drawings. It’s clear that great care and expertise went into the manufacturing process. The service provided was equally commendable. The communication was prompt, clear, and helpful from the initial quote to the final delivery. All my questions were answered thoroughly, and the team was very accommodating. This level of service makes the entire procurement process smooth and stress-free. I highly recommend their services for anyone in need of reliable and high-quality machined parts.

Rapid delivery was the first thing that impressed me. The parts arrived well ahead of the initial estimated timeline, which was a fantastic start. Regarding the quality, the precision of the machined components is exceptional. Every edge is clean, every thread is perfect, and the finishes on both the aluminum and stainless steel pieces are exactly as specified in the drawings, with no visible tool marks or imperfections. The service team was highly communicative and professional throughout the entire process. They promptly answered all my technical queries and provided clear updates on the order status without me having to chase them. The packaging was also very secure, with each part individually protected to prevent any transit damage. Overall, this was a seamless experience from quote to delivery. The combination of fast logistics, top-tier manufacturing quality, and attentive, proactive customer service makes this supplier a reliable partner for precision OEM components. I would not hesitate to place another order for future projects requiring CNC turning and milling services.

Quick delivery and excellent packaging. The parts arrived ahead of schedule, which was a pleasant surprise. The quality of the machined components is superb, with clean finishes and precise tolerances. Communication with the service team was prompt and helpful throughout the process. They answered all my questions clearly and provided updates without me having to ask. Overall, a very reliable and professional experience from start to finish. I would definitely use their services again for future projects. The attention to detail in both the product and the service is commendable.

Very satisfied with the overall experience. The vendor handled my order for custom CNC parts with great professionalism. Communication was clear and timely from the very beginning, which I value highly. Regarding logistics, the shipment was dispatched promptly and arrived exactly within the estimated timeframe. The packaging was secure and robust, ensuring all the precision components were well-protected during transit. There was no damage whatsoever upon arrival. As for the quality, the machined parts, made from a mix of aluminum and stainless steel as per my specifications, exhibit excellent craftsmanship. The tolerances are tight, the surface finish is smooth, and everything fits together perfectly in my assembly. The service team was responsive and helpful, addressing my preliminary technical queries efficiently. They provided useful insights during the quoting phase. While I haven't yet put the parts into their final operational environment, the initial inspection and measurements confirm a high standard of manufacturing. This vendor demonstrates a strong commitment to delivering reliable OEM manufacturing services. I would certainly consider them for future projects requiring CNC turning or milling services.

Excellent experience from start to finish. The logistics were handled flawlessly; my order was processed promptly and shipped ahead of the estimated schedule. Communication regarding shipping updates was clear and timely, which made planning on my end very straightforward. The quality of the machined parts is truly outstanding. Each component, whether in aluminum or stainless steel, exhibits impeccable precision and a flawless finish, meeting the exact specifications provided. The service provided by the team was exceptional. They were responsive, professional, and demonstrated a genuine commitment to ensuring customer satisfaction. Any preliminary questions were answered thoroughly, and the entire process felt collaborative and transparent. This level of dedication to logistics, quality, and service is commendable and sets a very high standard in OEM manufacturing. I am thoroughly impressed and would not hesitate to recommend their CNC machining services for any precision metal component needs. The overall reliability and excellence make them a top-tier partner for manufacturing.