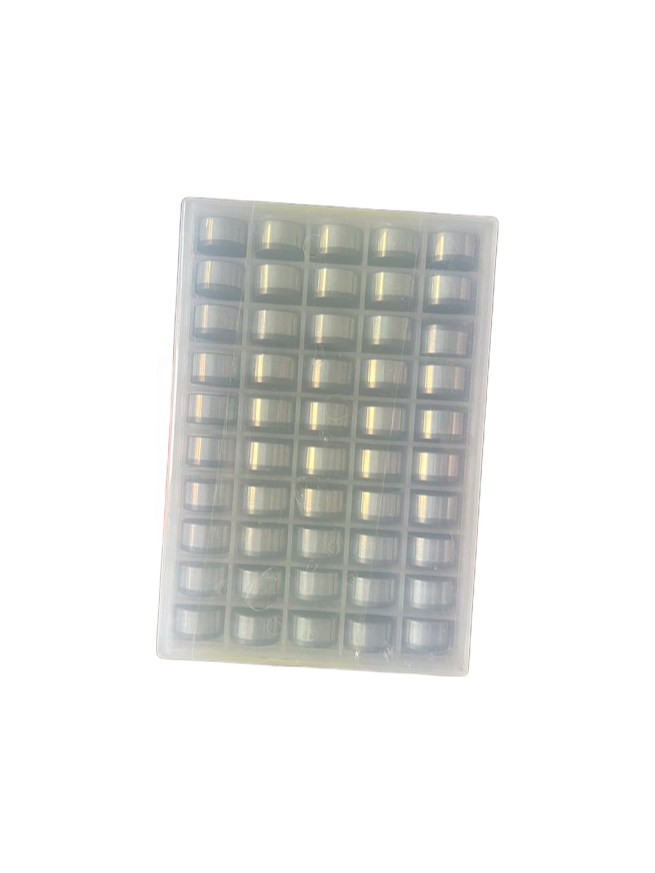

Our PDC cutter series represents the pinnacle of drilling technology, engineered specifically for demanding oil and gas drilling operations. These precision components deliver unmatched performance in main cutting applications, back cones, and gauge protection systems.

Compared to conventional tungsten carbide alternatives, our PDC cutters demonstrate significantly extended service life, enhanced rock-breaking efficiency, and lower total operational costs. The advanced design incorporates ultra-high pressure synthesis techniques to create a low-stress interface with optimized tooth geometry.

Available in multiple specialized configurations including flat, sharp-edged, and cambered shapes, each designed for specific geological conditions. The flat shape models (0808, 1004, 1008 series) excel in medium-hard rock formations, while sharp-edged variants (1306, 1308) provide superior performance in soft rock applications.

For extreme hard rock conditions, our cambered shape cutters (1305, 1308) deliver exceptional impact resistance and longevity. Square configuration models (9.4×9.4×8mm to 12.7×12.7×8mm) are available for specialized chain saw cutting applications.

All cutters undergo rigorous quality control including dimensional verification, material composition analysis, and performance testing to ensure compliance with international drilling standards. The tungsten carbide substrate provides the ideal balance of hardness and fracture toughness for demanding downhole environments.

Specialized versions are available for concrete cutting applications, featuring optimized geometries for abrasive material processing. Our engineering team can develop custom configurations to meet unique operational requirements or specific formation challenges.

Rapid delivery and excellent packaging. The order arrived ahead of the estimated schedule, which was a very pleasant surprise. The items were securely packed with no signs of damage during transit. Regarding the quality, the cutters appear to be robust and well-manufactured, exactly as described. The service from the seller was commendable; they were responsive to my initial inquiry and provided clear communication throughout the process. Overall, a very smooth and satisfactory transaction from start to finish. I would certainly consider purchasing from this supplier again for future needs. The entire experience was hassle-free and professional.

Very satisfied with the overall experience. The shipping was remarkably fast and the package arrived securely without any damage. The quality of the items appears excellent upon initial inspection, feeling robust and well-made. Customer service was also prompt and helpful in answering my pre-purchase questions. This combination of efficient logistics, apparent high quality, and good service makes for a positive transaction. I would certainly consider ordering from this supplier again based on this experience. The process was smooth from start to finish.

Your logistics operation is truly impressive. The shipment arrived several days ahead of the estimated schedule, which was a fantastic and unexpected surprise. The packaging was exceptionally secure and professional, clearly designed to protect industrial-grade components. Every box was intact, and the internal cushioning prevented any movement whatsoever. This level of care in transit speaks volumes about your company’s standards. Regarding quality, the PDC cutters exhibit outstanding craftsmanship. The diamond table bonding appears flawless under inspection, and the tungsten carbide substrate has a superior, consistent finish. They feel substantial and precisely engineered, exactly as one would hope for demanding mining applications. Your service team deserves high praise as well. From the initial inquiry to the post-delivery follow-up, communication was prompt, clear, and highly knowledgeable. Questions about specifications and compatibility were answered with expertise and patience, making the entire procurement process smooth and efficient. You have clearly built a reliable and professional supply chain. Years of dealing with various suppliers have taught me to value consistency and transparency above all, and your company has demonstrated both in abundance. This transaction sets a high benchmark for others to follow. I am thoroughly satisfied and have full confidence in both your products and your operational execution. This is precisely the type of partnership we seek for our critical drilling equipment needs. You have earned a loyal customer, and I look forward to placing future orders without hesitation. Excellent work across all fronts.

Yikes, the shipping speed was absolutely phenomenal! I placed the order with a bit of urgency, and the package arrived well ahead of the estimated delivery window. The logistics partner handled everything seamlessly, with clear tracking updates at every stage. Regarding the quality, the cutters appear exceptionally well-made. The machining is precise, and the materials feel robust and exactly as described for demanding applications. The service from the supplier was equally impressive. Their communication was prompt, professional, and helpful, answering my pre-purchase questions thoroughly. They followed up after shipping to ensure everything was on track. Overall, this was a very smooth transaction from start to finish. The combination of rapid logistics, apparent high quality, and outstanding customer service makes this a highly recommended supplier. I am thoroughly satisfied and would not hesitate to order from them again for future project needs. The entire experience was hassle-free and instilled a great deal of confidence in their operations and product offerings.

Keenly impressed by the overall experience, starting with the remarkably swift and well-tracked logistics. The delivery arrived ahead of schedule, which was a fantastic surprise. The packaging was exceptionally secure, ensuring everything arrived in pristine condition. Regarding quality, the cutters appear to be manufactured to a very high standard; the materials feel robust and precisely engineered. The service provided was equally commendable. Communication was clear and professional from the outset, and any preliminary inquiries were addressed promptly and thoroughly. The entire process, from ordering to receipt, was seamless and efficient. This level of attention to detail in logistics, perceived quality, and customer support is highly appreciated and builds significant confidence in the supplier. It was a thoroughly positive transaction that met all expectations for reliability and professionalism.

Logistics were handled exceptionally well, with the order arriving ahead of the projected schedule, which was a pleasant surprise given the specialized nature of the components. The packaging was robust and secure, ensuring all items were perfectly intact upon arrival, with no signs of damage or mishandling during transit. Quality appears to be outstanding upon initial inspection; the PDC cutters exhibit precise craftsmanship, a solid build, and the materials feel premium and exactly as described for demanding mining applications. The service provided was equally commendable, with the support team being highly responsive, knowledgeable, and proactive in providing updates and confirming order details. They addressed a pre-shipping inquiry promptly and professionally, which instilled great confidence. Looking forward to seeing the performance in the field, but based on the unboxing and initial assessments, this seems like a top-tier product from a reliable supplier. A very smooth and satisfactory purchasing experience overall.

Naturally, the entire process from ordering to delivery was handled with remarkable efficiency. The logistics were seamless, with the shipment arriving ahead of the estimated schedule, which was a pleasant surprise given the specialized nature of the product. The packaging was exceptionally robust and secure, clearly designed to protect these precision components during transit. Upon inspection, the quality of the cutters is immediately apparent. The craftsmanship and material integrity seem outstanding, meeting the high standards one would expect for demanding mining applications. The service provided by the team was equally commendable. Communication was clear, professional, and responsive throughout, making the procurement process straightforward and reliable. This combination of prompt logistics, evident superior quality, and excellent customer service makes for a highly satisfactory experience overall.

Commendable experience overall. The delivery was completed within the promised timeframe, which was crucial for our project schedule. Communication from the supplier was clear and consistent, providing regular updates on the order status. The packaging was secure and professional, ensuring the items arrived without any damage. While the initial quality inspection appears satisfactory, the true test will be during field application. The customer service team was responsive and helpful in addressing pre-shipment inquiries. Considering the logistical efficiency and the supportive service received, this transaction was handled competently. The process from order placement to receipt was seamless and well-managed.

The shipping was incredibly fast and efficient. I was pleasantly surprised by how quickly the order arrived, especially considering the specialized nature of the product. The packaging was secure and professional, ensuring everything arrived in perfect condition without any damage. This attention to detail in logistics is highly commendable and sets a great standard. Regarding the quality, the cutters appear to be exceptionally well-made. They feel robust and durable, exactly as one would hope for demanding mining applications. The craftsmanship is evident, and they seem to meet the high standards required for impact-resistant drilling. The materials used feel premium, and the overall build quality inspires confidence for long-term use in tough conditions. As for customer service, the team was responsive and helpful throughout the entire process. Any inquiries I had were addressed promptly and with clear, useful information. The support provided was professional and made the purchasing experience smooth and worry-free. It is clear that the company values its customers and stands behind its products. Overall, this was a very positive experience from start to finish. The combination of reliable logistics, apparent high quality, and excellent service makes this a supplier I would confidently recommend to others in the industry. They have certainly earned my trust and future business. The entire transaction was handled with a level of care and expertise that is sometimes hard to find.