ADV 508 - SR series sheet metal deburring machine is specially designed for heavy slag removal, deburring, edge rounding and oxide layer removal of thick carbon steel plates. Heavy slag, also known as dross, is molten metal generated on parts during thermal cutting operations such as oxy - fuel cutting, flame cutting and plasma cutting, and it must be removed to ensure subsequent processing or aesthetic requirements.

The standard effective processing width of this equipment is 800mm, 1100mm, 1400mm, and it can also be customized according to needs. The minimum machinable size is 30mm * 30mm (equipped with a vacuum or magnetic worktable). The belt size is 2000 * 820mm, and the conveying speed is controlled by frequency conversion between 0.5 - 8m/min, ensuring an efficient and stable processing process.

The equipment is equipped with a powerful motor configuration: the motor power of the cleaning hammer or sand block is 2.2 * 2kw, the motor power of the abrasive belt rotary brush is 11kw, the motor power of the conveying motor is 1.5kw, and the power of the optional vacuum adsorption motor is 15kw. The total motor power reaches 37kw, which guarantees the strong power of the equipment in processes such as heavy slag removal.

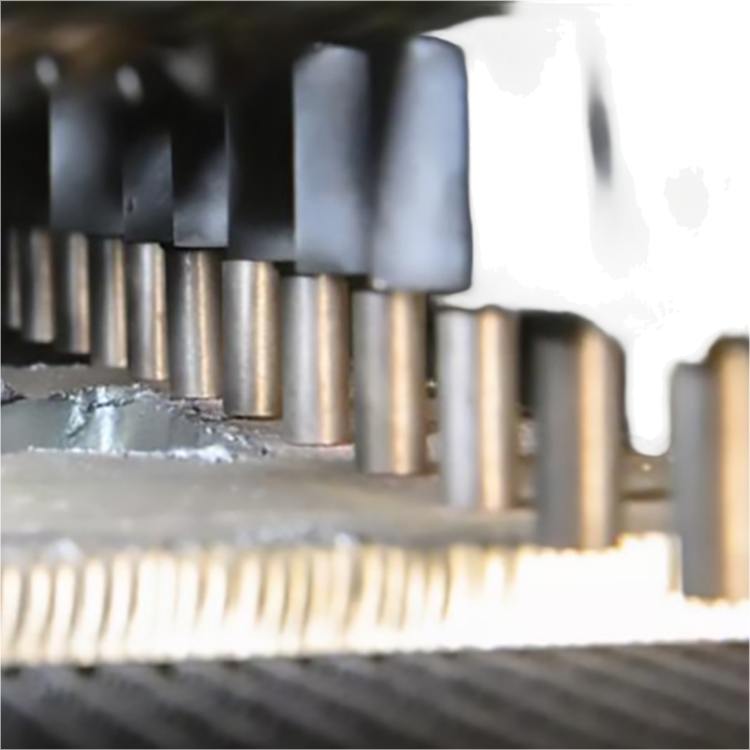

To deburr the edges and holes of the workpiece, the equipment is equipped with a set of cleaning hammer or sand block structure; an optional wide abrasive belt grinding head behind the S station can be used for edge breaking and further deburring. For the oxide scale generated by plasma cutting, this equipment can effectively remove it to ensure the smooth progress of subsequent coating or welding processes.

Available consumables include two rows of cleaning hammers (H station, suitable for heavy slag removal in plasma or oxy - fuel cutting) and two rows of sand blocks (S station, realizing the edge rounding function). The equipment size is 3200 * 1800 * 2400mm, with a compact structure and stable performance. It has the advantages of time - saving, cost - saving and excellent performance, considering everything for customers and creating more value for them.

The application scenarios of this equipment are extensive: metal slag not only affects the strength and protection of metal, but also affects the appearance, and will hinder the adhesion of surface coatings. Whether it is a steel plate cut by plasma or flame, ADV 508 - SR can be processed efficiently. Just tell us the maximum width of the material, and we can recommend the appropriate size of the equipment.

We support free sample testing for customers. If you have any questions about the sheet metal deburring machine, please feel free to consult. The equipment is CE certified and provides a 2 - year warranty, with technical materials such as basic drawings, manuals and electrical wiring diagrams attached to ensure that customers have no worries when using it.

Shipping was surprisingly swift and well-coordinated. Several logistical updates were provided throughout the transit, which made tracking the substantial machinery straightforward. The packaging was exceptionally robust, ensuring the large machine arrived without a single scratch or dent, which is crucial for heavy industrial equipment. Superb communication from the sales team was maintained from the initial inquiry right through to the final delivery confirmation. They were proactive and informative, addressing all pre-shipment questions promptly. Regarding the machine’s build, the initial inspection reveals a very solid and sturdy construction. The welding and assembly appear to be of high quality, exactly as one would expect for a customized piece of heavy-duty equipment. The overall service experience has been seamless and professional, instilling great confidence in this supplier for future industrial needs.

Delivery was impressively prompt, with the machine arriving well ahead of schedule. The packaging was exceptionally robust, ensuring every component was perfectly secure. From initial inquiry to final delivery, the logistics coordination was seamless and professional. The build quality of the machine is immediately apparent; it feels solid, durable, and precisely manufactured. The attention to detail in the construction is commendable. Customer service has been outstanding throughout this process. The support team was responsive, knowledgeable, and proactive in providing updates. They patiently addressed all pre-delivery questions and followed up to ensure a smooth handover. This level of service is truly refreshing and builds immense confidence in the supplier. Overall, a flawless experience from start to finish, highlighting excellent operational efficiency and a strong commitment to customer satisfaction.

Rapid delivery was the first thing that impressed me. The logistics were handled exceptionally well, with clear tracking updates provided at every stage. The machine arrived well ahead of the estimated schedule, which was a fantastic start. Regarding the build quality, it is immediately apparent that this is a robust and heavy-duty piece of equipment. The construction feels solid and precise, exactly as one would hope for a machine designed for heavy slag removal. The finish and assembly appear to be of a very high standard. Customer service throughout the entire process was outstanding. The team was responsive, knowledgeable, and proactive in their communication. They provided all necessary documentation and were available to answer pre-delivery questions promptly. The overall experience, from initial inquiry to the machine arriving at our facility, was seamless and professional. The packaging was secure and appropriate for such a large item, ensuring it was protected in transit. This level of attention to detail in logistics, the evident quality of the manufacturing, and the superior service provided gives me great confidence in this supplier. It was a very satisfactory procurement experience from start to finish.

Meticulous attention to logistics was evident from the start. The shipping timeline provided was accurate, and the machine arrived precisely within the promised window. The packaging was exceptionally robust, clearly designed to protect such a heavy-duty piece of industrial equipment. Every crate was securely fastened, and there was no sign of damage or mishandling during transit. The freight forwarder was professional, and the delivery team handled the unloading with appropriate care and equipment. The entire logistical chain, from the factory to our dock, was seamless and communicated effectively. Regarding quality, the initial inspection reveals a machine built with substantial materials. The construction feels solid and industrial-grade, exactly as one would expect for a heavy slag removal application. The welds are clean, the belt mechanism aligns perfectly, and the overall fit and finish are impressive. It has the heft and precision of a custom-engineered solution. The service provided by the sales and support team has been outstanding. They were responsive to all pre-purchase inquiries, providing detailed specifications and customization options without pressure. Post-order, they maintained clear communication, sending regular updates on the manufacturing and shipping status. Their technical department was readily available to discuss integration plans for our facility. This level of proactive and professional service is commendable and instills great confidence in the partnership. Overall, the experience surrounding the acquisition of this deburring machine has been highly positive, marked by reliable logistics, apparent build quality, and exemplary customer service.

Excellent experience overall! The delivery was incredibly fast, arriving well ahead of schedule, which was a fantastic surprise. The packaging was robust and secure, ensuring the machine arrived in perfect condition without a single scratch. Regarding quality, the construction feels exceptionally solid and durable, exactly as described for heavy-duty industrial use. The initial inspection shows precise workmanship. Customer service was outstanding; the support team was responsive and helpful with the pre-delivery logistics, answering all queries promptly and professionally. A very smooth and satisfactory transaction from start to finish.

Keenly satisfied with the overall experience regarding this deburring machine purchase. The logistics process was exceptionally smooth and transparent. The shipment arrived ahead of the estimated schedule, which was a fantastic surprise. Every update was communicated clearly, and the packaging was robust and secure, ensuring the equipment was perfectly intact upon arrival. Regarding quality, the machine appears to be constructed with durable materials and solid craftsmanship, exactly as described for heavy-duty slag removal. The initial inspection shows great promise for its intended use on plasma and flame-cut steel. The service provided was outstanding from the initial inquiry through to post-delivery follow-up. The team was responsive, knowledgeable, and professional, addressing all pre-sale questions with patience and clarity. They provided excellent support in coordinating the delivery. This level of attentive service made the entire procurement process remarkably straightforward and stress-free. A highly commendable experience from start to finish.

Just outstanding experience from start to finish! The delivery was incredibly fast, arriving days ahead of schedule without any delays or damages. Juggling tight production timelines, this prompt logistics service was a lifesaver, ensuring our operations continued smoothly. Regarding quality, the machine’s construction is robust and precise, showing no defects upon inspection—it clearly meets high standards for durability. Customer service was equally impressive; the team was responsive, answered all queries thoroughly, and provided helpful updates throughout. Joining efficiency with reliability, this purchase has been seamless and highly satisfactory. I wholeheartedly recommend them for anyone needing dependable equipment with top-notch support.

Yippee! The delivery was incredibly fast and well-handled, arriving right on schedule without any hiccups. Your logistics team deserves a big shout-out for their efficiency and careful handling of such a large item. As for quality, the machine appears robust and well-constructed, giving me confidence in its durability for industrial use. The service was top-notch too; the support staff were responsive and helpful throughout the process, answering all my queries promptly. Overall, a fantastic experience that I'd gladly recommend to others in the metalworking industry.