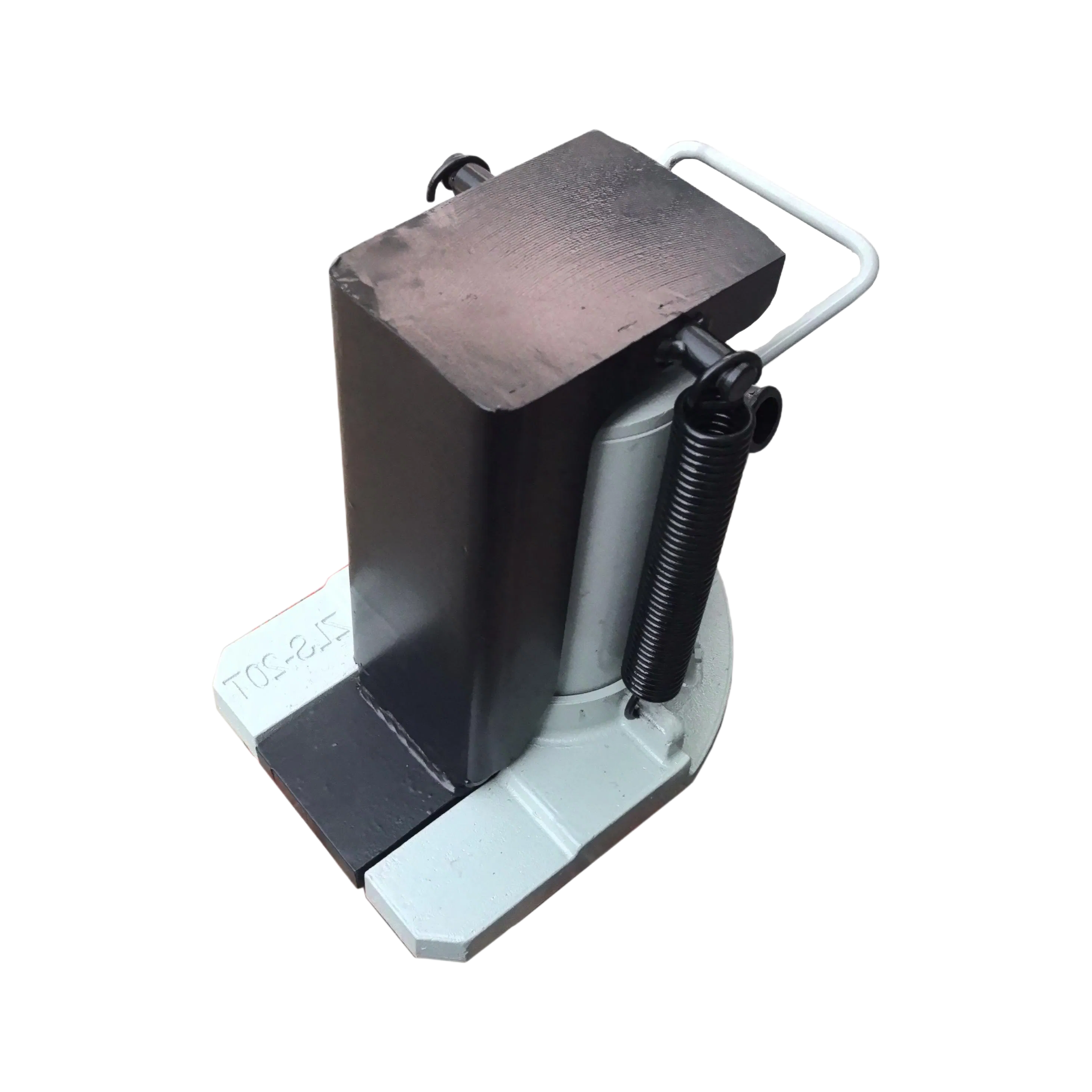

Hydraulic claw jacks are engineered for efficient equipment lifting and support across various industrial sectors. These jacks are celebrated for their safety, portability, durability, and extended service life, making them indispensable in automobile manufacturing, casting machinery, transportation, factory construction engineering, and bridge construction. They ensure secure and reliable lifting operations, enhancing productivity and safety on-site.

The product range includes multiple models such as 5T, 10T, 20T, and 30T, each designed with specific dimensions and capacities to meet diverse industrial needs. Key features include a double-sealed wear-resistant cylinder that prevents oil leakage, micron precision matching with alloy material tempering for enhanced durability, and refined steel casting integrated forming for stability and thickness. The alloy material undergoes a quenching process to achieve a mirror-smooth finish, while the high-strength forged plate and built-in anti-overload device ensure operational safety.

Operation is straightforward: to jack up, clamp the handle lever on the drain valve stem, turn it clockwise without overtightening, insert the handle bar, and shake it up and down. To lower, clamp the handle lever and slowly unscrew counterclockwise, avoiding rapid unscrewing and not exceeding three turns. These jacks are versatile and reliable for various heavy-duty applications.

Delivery was impressively fast and the packaging was very secure, which I truly appreciate. The quality of the jack feels robust and well-made, exactly as described for industrial use. Customer service was responsive and helpful when I had a pre-sale question. Definitely a positive experience overall.

Great experience overall. The shipping was surprisingly fast, arriving well ahead of the estimated delivery window. Everything was packaged securely with no signs of damage during transit. The quality of the materials and construction feels very solid and robust, exactly what you would expect for industrial equipment. The communication from the supplier was prompt and professional, answering all pre-purchase questions clearly. While I haven't put the jacks through their full paces yet in a working environment, the initial inspection and handling are very promising. The build appears to be durable and the safety features are clearly integrated into the design. The ordering process was straightforward, and the service team was helpful in confirming the order details. For a wholesale purchase, the logistical efficiency was particularly appreciated, making the procurement process smooth from start to finish. The product presentation upon unboxing was also neat and professional, which reflects well on the factory's standards. Based on first impressions regarding logistics, apparent quality, and customer service, this seems like a reliable supply source for such specialized equipment. The anti-overload features are a significant point of confidence, and the overall sturdiness suggests a long service life as advertised. A very satisfactory transaction so far, focusing purely on the acquisition and initial assessment phases.

Delivery was exceptionally prompt and handled with great care. The packaging was robust and secure, ensuring the product arrived in perfect condition without any signs of damage. The communication regarding shipping updates was clear and timely, which I greatly appreciate. Regarding the item itself, the build quality is outstanding. It feels solid, durable, and precisely manufactured, exactly as described. The finish is professional, and all components fit together perfectly. The service provided was excellent from start to finish. Any pre-purchase inquiries were answered quickly and thoroughly with helpful information. The overall experience was smooth and professional. I am very satisfied with this transaction and would confidently recommend this supplier to others based on this positive experience. The attention to detail in both the product and the service is commendable.

Craftsmanship and care define this transaction from start to finish. The logistics were handled with impressive efficiency; the shipment arrived ahead of the projected schedule, which was a welcome surprise. Every component was securely packaged, showing clear attention to detail in preventing transit damage. Regarding quality, the initial inspection reveals robust construction and precise machining. The materials feel substantial and durable, exactly as one would hope for in industrial-grade equipment. The finish is clean, with no visible defects or rough edges, suggesting good manufacturing controls. The service aspect was equally commendable. Communication was proactive and clear, with all my inquiries answered promptly and thoroughly. The documentation provided was complete and accurate. Overall, this was a seamless wholesale purchasing experience. The combination of reliable logistics, apparent product integrity, and professional service instills confidence. It sets a solid foundation for a potential ongoing supply relationship. This level of execution in all operational facets is precisely what one seeks in a factory supplier for critical equipment.

I am thoroughly impressed with the overall experience of purchasing these hydraulic claw jacks. The logistics were handled exceptionally well; my order arrived much faster than anticipated, and the packaging was secure, ensuring that the products were in perfect condition upon delivery. The quality of the jacks is outstanding, with robust construction that clearly reflects their anti-overload safety features and promises a long service life. Additionally, the customer service team was highly responsive and professional, promptly addressing my inquiries and providing helpful assistance throughout the process. I highly recommend this supplier for their reliability and excellent standards.

Excellent experience overall! The shipping was incredibly fast, arriving much sooner than expected, which was a pleasant surprise. The packaging was secure and ensured the product arrived in perfect condition without any damage. As for quality, the materials feel robust and durable, giving confidence in long-term use. Customer service was outstanding; they were responsive and helpful with my inquiries, making the process smooth. Highly satisfied with this purchase and would recommend to others looking for reliable industrial equipment.

Naturally, I was impressed by the swift delivery of the hydraulic claw jacks; they arrived well-packaged and ahead of schedule, which minimized any downtime for our operations. The quality is outstanding, with robust construction that feels durable and reliable for heavy-duty use. Additionally, the customer service team was exceptionally responsive and helpful, addressing all my inquiries promptly and professionally. Overall, a fantastic experience from start to finish.