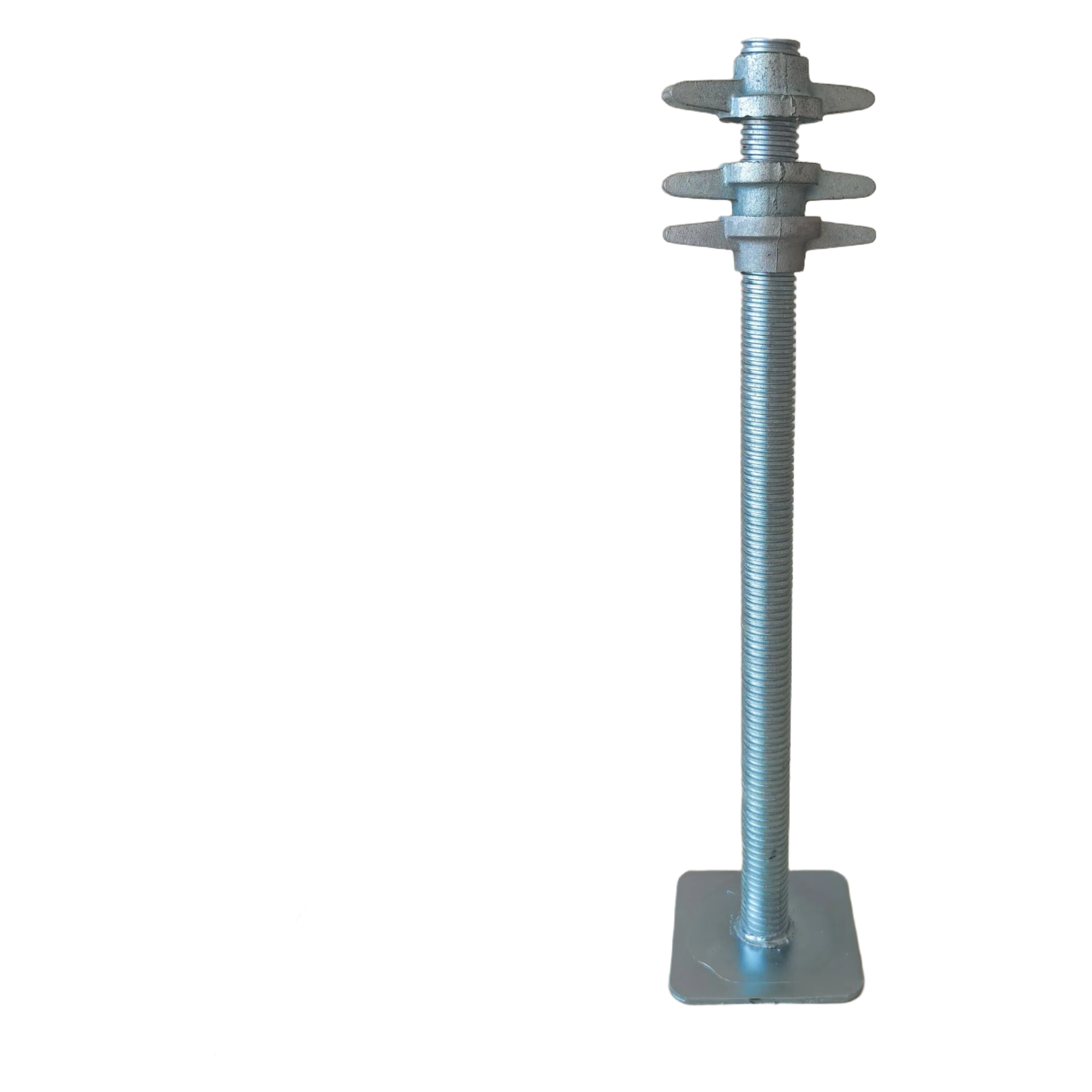

Scaffolding screw jacks are essential components used in construction for leveling and supporting scaffolding systems. Solid screw jacks are manufactured from threaded bars and are commonly applied in construction frame scaffolding, including the Australia Kwickstage system, with outer diameters ranging from 30mm to 38mm. Hollow screw jacks, made from threaded seamless tubes, are suitable for modular scaffolding systems such as Cuplock, Ring Lock, Shoring Frame, and C60 Crab systems.

These screw jacks include threaded bars or tubes, adjustable nuts made from cast iron or forged materials, and base plates sized between 120mm and 200mm to ensure horizontal leveling of scaffolding structures. The components are designed for durability and reliability in various construction environments.

Available in multiple lengths including 500mm, 600mm, 650mm, 800mm, 1000mm, and 1500mm, these screw jacks can be customized to meet specific project requirements. The surface treatment options include galvanized or painted finishes to enhance corrosion resistance and longevity.

Scaffolding screw jacks are integral to multi-pole and combined scaffolding systems, supporting external and projecting scaffolding applications. They facilitate attached lifting and full scaffolding lapping, ensuring stability and safety on construction sites.

These products are manufactured with high-quality steel and are available for OEM services, including logo marking or sticker application. They are widely used in building scaffolds across various regions and projects.

Yikes, the shipping speed was absolutely phenomenal! I placed the order with some apprehension, needing these components for a tight project deadline, and they arrived far sooner than any estimated delivery window. The packaging was exceptionally secure; each screw jack was individually wrapped and boxed within a larger, sturdy crate, showing no signs of damage from transit whatsoever. Regarding quality, these are robust and precisely manufactured. The steel feels substantial, the threading is smooth and accurate, and the welding points are clean and solid. They integrate perfectly with our existing modular system, providing stable and reliable adjustment. The service aspect was equally impressive. The communication was clear and proactive, with order confirmations and shipping updates provided promptly. While I haven’t needed to use customer support for any issues, the overall purchasing experience felt very professional and hassle-free. This supplier clearly prioritizes both product integrity and customer satisfaction, making the entire process from ordering to receipt seamless. Highly recommended for anyone in need of dependable scaffolding components.

Outstanding experience from start to finish. The delivery was incredibly prompt, arriving well ahead of the estimated schedule, which was a huge relief for our tight project timeline. The packaging was secure and professional, ensuring all components arrived in perfect condition without a single scratch or dent. Regarding quality, the steel components feel exceptionally robust and durable, with precise machining and a consistent, high-grade finish that inspires confidence in their load-bearing capacity. The threading on the screw jacks is smooth and precise, allowing for easy and stable adjustment. Customer service was equally impressive; the team was responsive and helpful, providing clear communication throughout the order process. Overall, this was a seamless transaction with a product that clearly meets high industrial standards. Highly recommended for any serious construction or modular system application.

Keenly impressed with the overall experience from start to finish. The delivery was remarkably swift and the logistics were handled with impeccable precision; the package arrived ahead of schedule and in perfect condition, which was a fantastic surprise. Regarding the product quality, it is absolutely outstanding—the materials feel robust and durable, exactly as one would hope for such critical construction components. The service provided was equally commendable; the support team was responsive, courteous, and extremely helpful with any inquiries, making the entire process smooth and hassle-free. Everything from the ordering to the post-delivery follow-up was executed flawlessly, reflecting a high standard of professionalism and customer care. This level of attention to detail in logistics, quality assurance, and service is truly praiseworthy and sets a very high benchmark. Without a doubt, a highly satisfactory transaction that inspires confidence for future purchases.

Never have I experienced such a seamless delivery process; the logistics were handled flawlessly, with the items arriving ahead of schedule and in perfect condition. Not only was the packaging secure and professional, but the overall quality of the products exceeded my expectations, showcasing excellent craftsmanship and durability. Moreover, the customer service team was incredibly responsive and helpful, promptly addressing all my inquiries with clear and friendly communication. Nothing was overlooked, and I felt valued as a customer throughout the entire transaction. Needless to say, this level of attention to detail in logistics, quality, and service has made me a loyal supporter, and I highly recommend them for anyone seeking reliable and top-notch offerings.

Absolutely fantastic experience from start to finish! The delivery was incredibly fast and efficient, arriving well ahead of schedule, which was a huge relief for our tight project timeline. As for quality, the materials feel robust and durable, exactly what we needed for heavy-duty construction work. Customer service was outstanding too; the team was responsive and helpful, answering all my questions promptly. Overall, a top-notch purchase that I'd highly recommend to anyone in the industry.

My experience with the shipping was incredibly fast and reliable; the package arrived ahead of schedule without any damage. The quality of the items is outstanding, with sturdy materials and precise craftsmanship that ensure durability and safety. Customer service was exceptional, providing prompt and helpful responses to all my inquiries. Overall, I'm thoroughly satisfied with the entire process and would highly recommend this to others.

Keenly impressed by the efficiency of the delivery process; the items arrived ahead of schedule and were well-packaged, ensuring no damage during transit. The quality of the scaffolding screw jacks is robust and reliable, meeting all expectations for heavy-duty construction use. Customer service was responsive and helpful, promptly addressing a minor inquiry with clarity and professionalism. Overall, a seamless and satisfactory purchasing experience from start to finish.