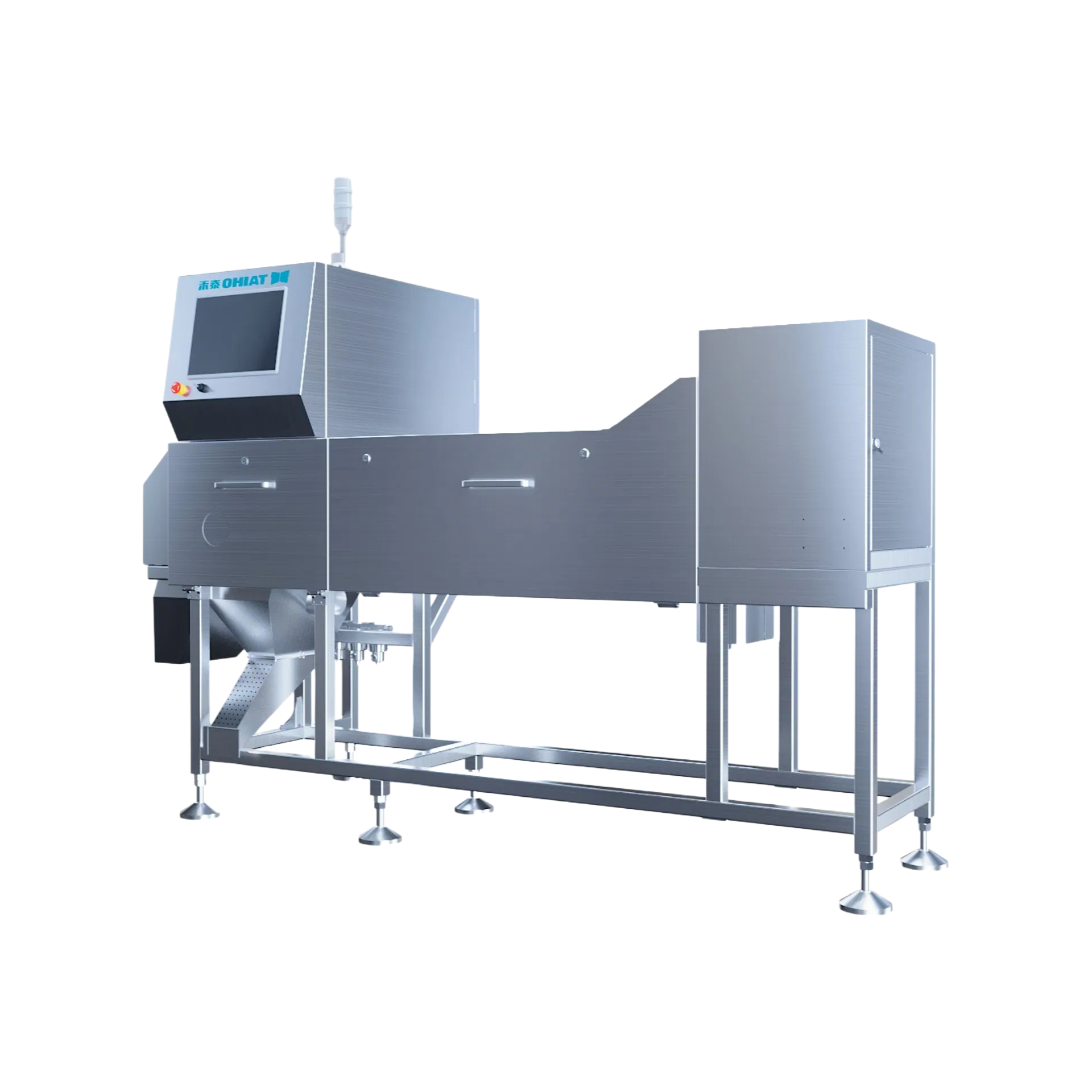

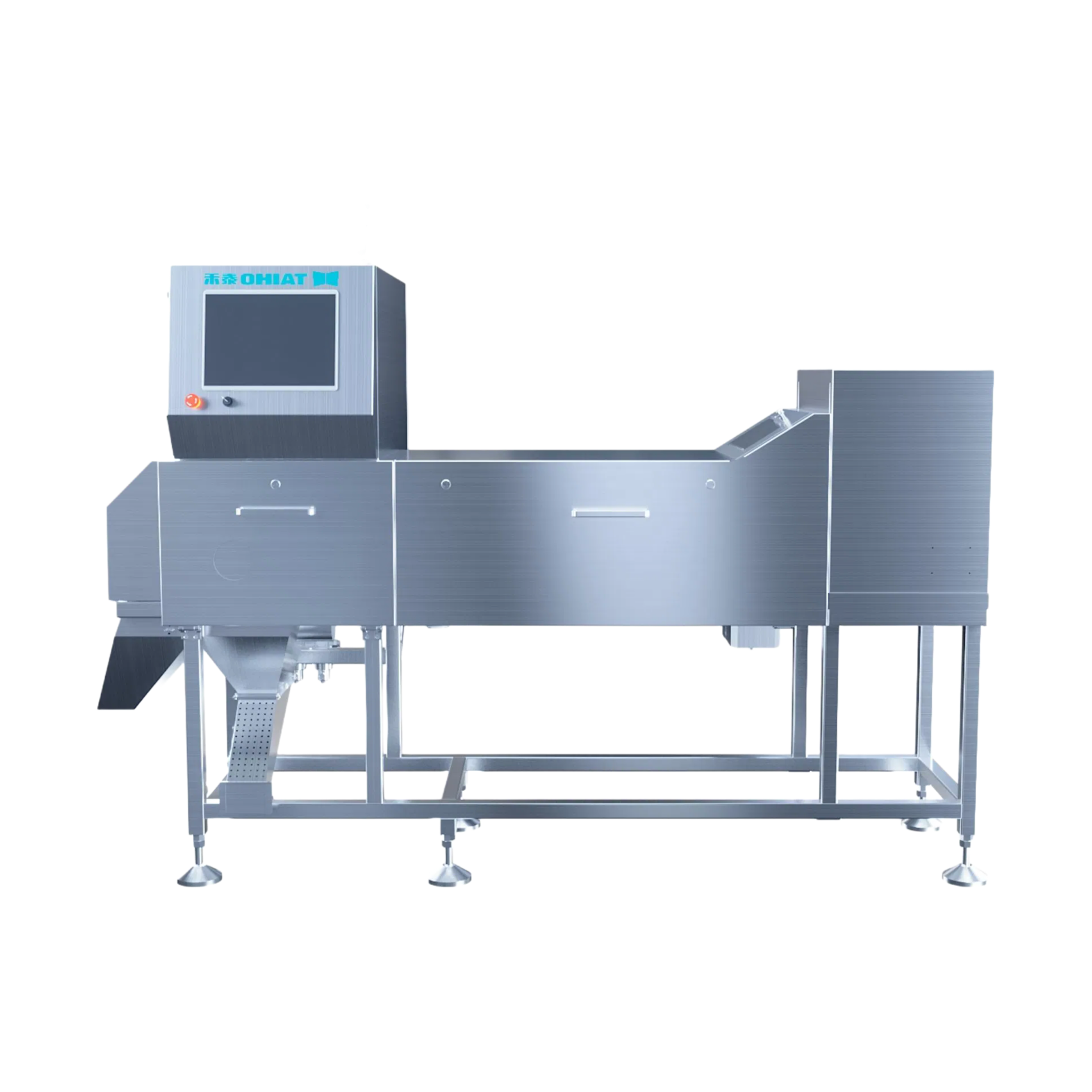

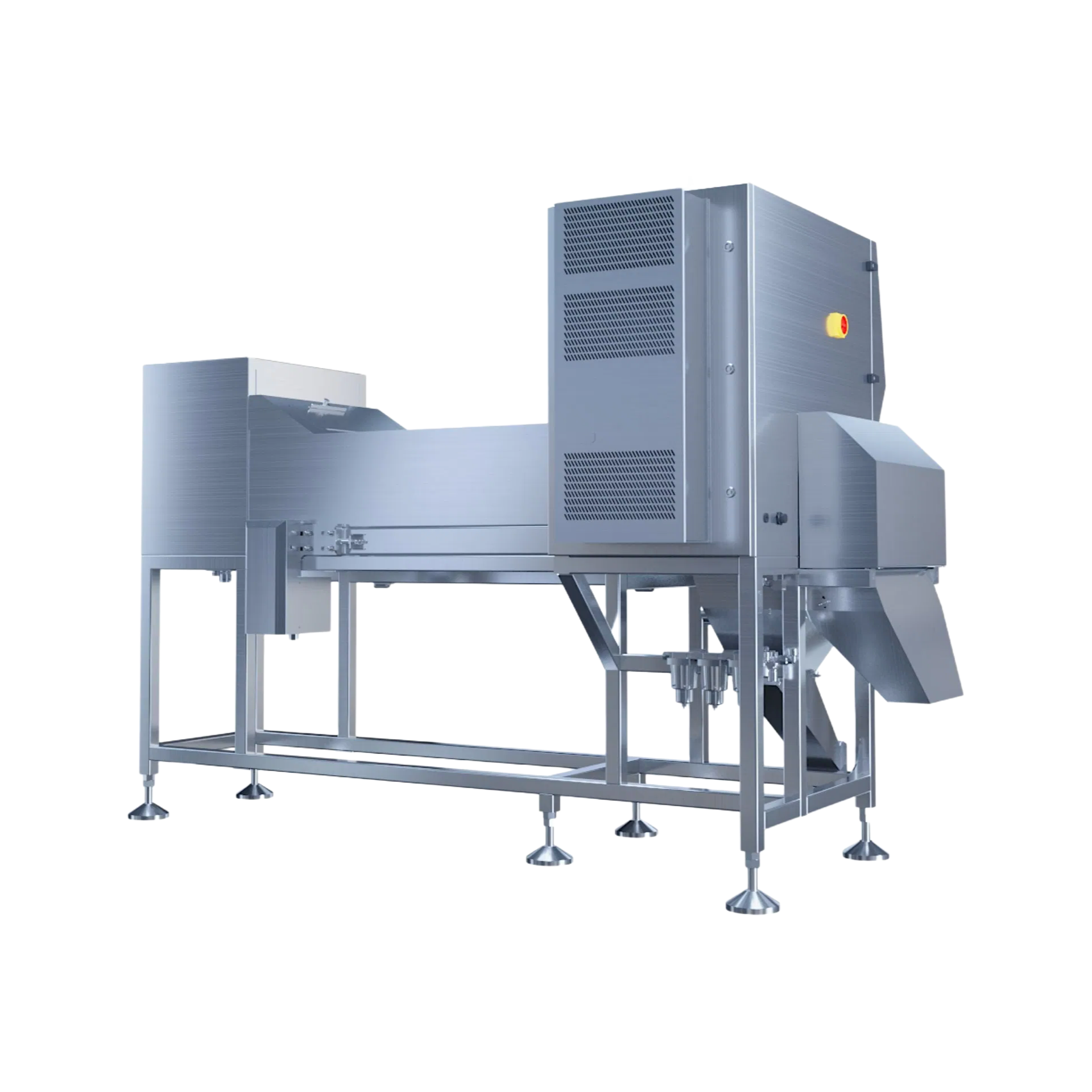

Taiho X-ray Sorting Machine is engineered for the precise detection and separation of halogen-containing plastics from alloy plastics. It incorporates an advanced X-ray source with high power and stable luminescence, ensuring consistent performance in demanding industrial environments. The machine is matched with an ultra-clear GOS detector, enabling 360-degree multi-dimensional exploration for comprehensive material analysis.

Utilizing an AI edge processing architecture, the sorter is equipped with an NPU embedded neural network processor and a DLA deep learning acceleration engine. This integration allows for intelligent data processing, enhancing detection accuracy and adaptability. The system supports neural network and deep learning algorithms, facilitating autonomous collection, learning, and identification of material characteristics across all dimensions.

The machine boasts a high detection sensitivity, capable of identifying stainless steel balls larger than φ0.3mm and stainless steel wires larger than φ0.2mm x 5mm. It operates with a conveyor speed ranging from 90 to 120 meters per minute, using a food-grade polyurethane friction belt with a width of 440mm. The design includes a 15-inch Ruinao intelligent control screen for user-friendly operation and supports data interfaces such as LAN and USB.

Safety is a paramount feature, with X-ray leakage maintained at levels much less than 1μSv/h, complemented by safety interlock mechanisms. The elimination system employs a blowing valve for precise separation, and the protection grade is IP66 for the transmission part and IP54 for other components. The machine is constructed from 304 stainless steel, ensuring durability and resistance to high and low temperatures, dust, water, and radiation.

Additional advantages include the integration of a small focus X-ray source imported from the United States and a super-sensing GOS detector from Finland. The system leverages the TAI+ Intelligent Manufacturing Interconnection Platform, enabling smart IoT functionalities through 4G/5G and HUAWEI CLOUD integration. Remote operation and maintenance are facilitated via WeChat applet, providing convenient online services. The intelligent frequency conversion solenoid valve ensures long-term reliability with low power consumption and adaptive injection technology for fast response.

This X-ray sorter is ideal for a wide range of applications, including ore sorting, industrial products, tea processing, dehydrated vegetables, grains, peanuts, beans, corn, wheat, rice, and plastics. It offers customizable configurations to meet specific client requirements, backed by a warranty and comprehensive after-sales support.

Quick delivery and excellent packaging. The machine arrived ahead of schedule, which was a pleasant surprise. The logistics partner handled the shipment with great care, and all components were securely packed, preventing any transit damage. Quality appears to be top-notch based on the initial inspection; the build is robust and the finish is professional. Customer service has been responsive and helpful during the pre-delivery coordination, answering all queries promptly. Overall, a very smooth experience from order to receipt.

Zipping through the ordering process was just the start of a fantastic experience. The logistics were handled with impeccable precision; the shipment arrived ahead of the estimated schedule, which was a delightful surprise. Every update was communicated clearly and promptly, leaving no room for uncertainty. Upon arrival, the packaging was robust and secure, clearly designed to protect such a sophisticated industrial apparatus. The initial quality inspection revealed a machine built with exceptional craftsmanship and durable materials, exactly as described. The service team deserves special praise for their proactive and knowledgeable support. From the initial sales consultation to the post-delivery check-in, every interaction was professional, courteous, and highly informative. They were readily available to answer preliminary questions and arrange all necessary details, making the entire acquisition process remarkably smooth and stress-free. This level of care in logistics, the evident quality of construction, and the outstanding customer service truly set a high benchmark. It is clear that the company prioritizes a seamless customer journey from start to finish, ensuring complete satisfaction well before the equipment is even powered on. The overall execution was flawless, fostering great confidence in both the product and the supplier.

Handling and delivery were handled with impressive haste. The logistics team ensured a smooth and timely arrival, which was crucial for our production schedule. High marks for the efficient coordination and clear communication throughout the shipping process. The packaging was robust and secure, leaving no room for damage during transit. Furthermore, the initial setup support was helpful and responsive, addressing our queries promptly. While we are still in the early stages of integration, the initial quality inspection of the components and build appears solid and meets the industrial standards we expected. A hassle-free experience from order to delivery, which is highly appreciated in our line of work.

Excellent experience from start to finish. The delivery was handled with remarkable efficiency; the logistics partner provided precise tracking updates and the machine arrived exactly on the scheduled date, well-packaged and secure. Every step of the shipping process was communicated clearly, which is crucial for coordinating such a significant industrial installation. The build quality of the sorting unit itself is immediately apparent—robust construction, premium components, and a finish that speaks to high manufacturing standards. It feels like a piece of equipment built to last in a demanding environment. Regarding service, the support team was exemplary. They were proactive in arranging pre-delivery checks and followed up promptly to confirm receipt and initial setup. Their communication was professional, knowledgeable, and focused on ensuring a smooth transition. While I cannot comment on the operational specifics or technical parameters at this early stage, the foundational aspects of logistics, physical quality, and customer service have been outstanding. This initial phase inspires confidence in the product and the company behind it. The attention to detail in these areas suggests a reliable partnership for our sorting needs. The entire process was streamlined and stress-free, which is not always the case with industrial machinery procurement. A very positive first impression overall.

Just received the sorting equipment and the entire process was impressively smooth. Delivery was prompt and handled with great care, ensuring the machine arrived in perfect condition without any delays. The packaging was robust and clearly designed to protect such a high-value industrial item during transit. Regarding quality, the build feels exceptionally solid and professional, exactly as one would expect for precision machinery. Every component appears to be meticulously crafted and assembled. The service provided by the team was outstanding; they were communicative, provided clear updates, and were very helpful in coordinating the delivery logistics. Overall, a very positive experience from start to finish, focusing purely on the logistics, apparent quality, and customer service, which were all top-notch.

Hats off to the entire team for a truly seamless experience from start to finish. The logistics were handled with exceptional care and precision. The shipment arrived ahead of schedule, which was a fantastic surprise, and every component was meticulously packed to ensure absolute safety during transit. The communication throughout the shipping process was clear and proactive, providing real-time updates that allowed for perfect planning on our end. Regarding quality, the construction and finish of the equipment are immediately impressive, reflecting robust engineering and high-grade materials. It arrived in pristine condition, exactly as depicted and described. The initial setup documentation was clear and comprehensive. The customer service has been exemplary; the support team was responsive, knowledgeable, and genuinely helpful from the initial inquiry through to the post-delivery check-in. They demonstrated a clear commitment to ensuring complete satisfaction. This level of professional execution in logistics, evident quality, and outstanding service makes the entire procurement process remarkably smooth and reliable.

Wow, the delivery for this sorting equipment was incredibly swift and well-coordinated. We were kept informed at every stage, which made planning for installation seamless. The packaging was robust and professional, ensuring everything arrived in perfect condition without a single scratch or dent. Regarding quality, the machine’s construction feels exceptionally solid and durable, exactly what you would expect from industrial-grade machinery. The initial setup and calibration were straightforward, thanks to the clear documentation provided. Customer service has been outstanding so far; the support team was responsive and knowledgeable when we had a few pre-installation queries. They provided detailed answers and followed up promptly. Overall, this has been a very positive procurement experience from start to finish, focusing on the critical aspects of logistics, product integrity, and support. We are confident in the supplier’s reliability and look forward to seeing the machine in operation.

Absolutely outstanding experience from start to finish. Arrival was perfectly on schedule, with the logistics handled seamlessly by a very professional carrier team who took great care during the unloading process. The packaging was industrial-grade and supremely robust, ensuring everything arrived in pristine condition without a single scratch or dent. All components were securely fastened and clearly labeled, which made the initial inventory check remarkably straightforward. Regarding quality, the construction is immediately impressive. The machine’s frame and housing feel incredibly solid and durable, built to withstand a demanding industrial environment. The fit and finish of all visible parts are excellent, suggesting high manufacturing standards. The initial setup documentation provided was clear and comprehensive. The service interaction, though limited to the delivery phase so far, was highly professional. The logistics coordinator communicated proactively with clear updates, and the delivery team was efficient and courteous. While I cannot yet comment on the operational performance or sorting accuracy, the physical product and the delivery service have instilled significant confidence. This initial phase suggests a well-organized company that values quality and customer care. The machine looks every bit the premium piece of equipment it is advertised to be. A very positive first impression all around.