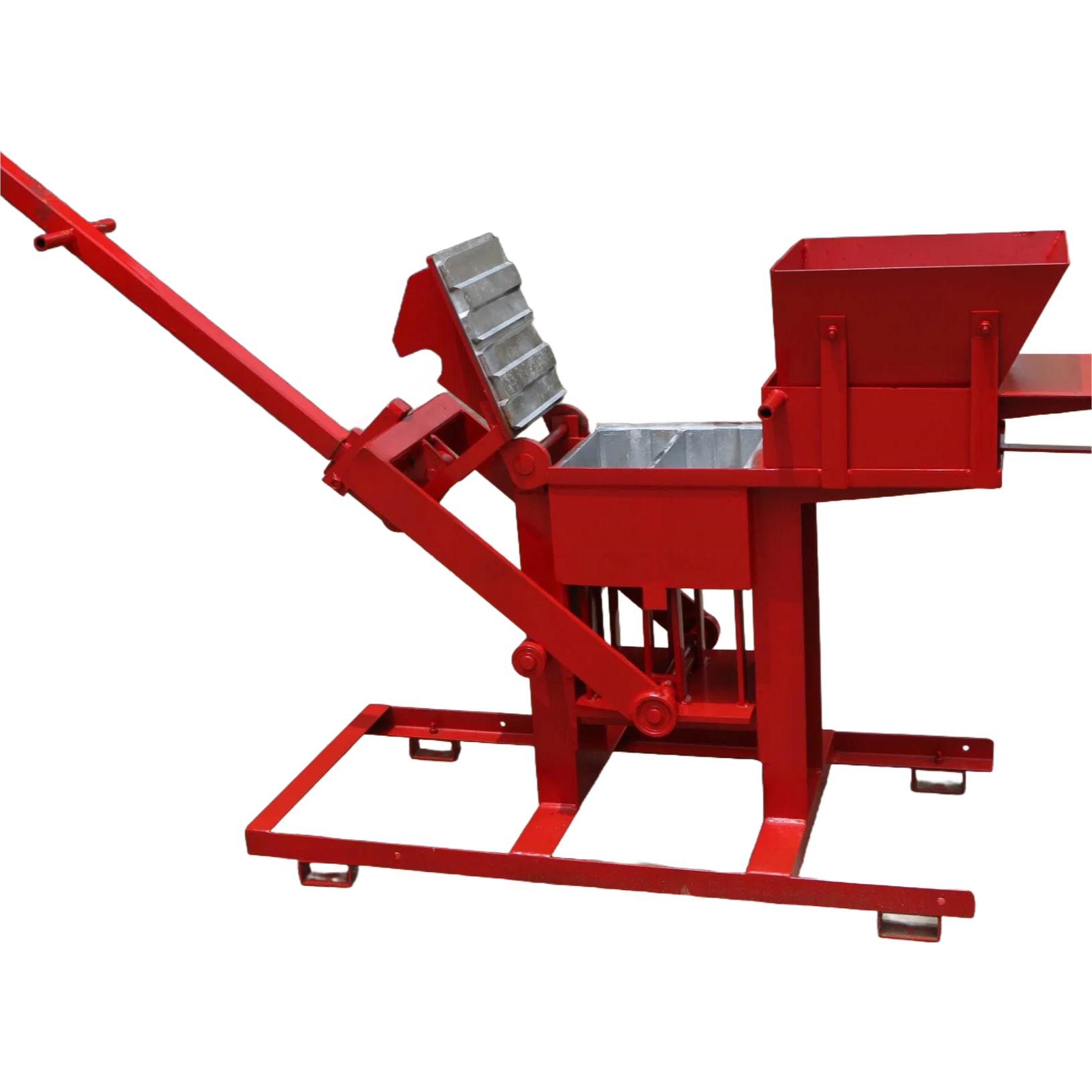

The RL2-40 manual interlocking brick making machine is an innovative solution for sustainable construction projects. This human-operated machine requires no electricity, making it ideal for remote areas or locations with limited power access.

With its compact dimensions of 1600*700*1200mm and weighing only 340kg, the RL2-40 offers exceptional portability. The machine can be easily relocated to different job sites as needed, providing flexibility for various construction projects.

The RL2-40 operates on a simple hydraulic principle, applying 10MPa pressure to form high-quality interlocking bricks. Each molding cycle takes just 30-40 seconds, with a capacity of 2 bricks per mold, ensuring efficient production rates for small to medium-scale operations.

Key advantages of the RL2-40 include:

- Environmentally friendly operation with no fuel or electricity requirements

- Low material consumption for cost-effective production

- Simple operation requiring minimal training

- Customizable molds for various brick designs

- Durable construction with CE certification

The machine processes natural materials including clay, soil, or sand mixed with water, creating sturdy interlocking bricks suitable for various construction applications. The interlocking design eliminates the need for mortar in many cases, further reducing construction costs.

For enhanced productivity, the RL2-40 can be paired with optional equipment like the JQ350 mixer to prepare raw materials efficiently. The complete system requires only two workers to operate, making it a labor-efficient solution.

Customization options include various brick patterns and colors to meet specific project requirements. The machine's simple maintenance requirements and durable construction ensure long service life with proper care.

Great experience overall. The shipping was surprisingly fast, especially considering the size and weight of the machine. It arrived well-packaged and without any visible damage from the long journey. The communication from the seller was prompt and clear throughout the process, answering all my preliminary questions. Upon unboxing, the initial impression of the build quality is very solid. The steel frame feels robust and the hydraulic components seem well-made. Assembly instructions were provided, though a bit basic, but customer service was helpful when I had a query. The paint finish is even and the machine operates smoothly in manual tests. While I haven't put it into full production yet, the initial dry runs are promising. The service team followed up to ensure delivery was complete, which was a nice touch. For a direct factory purchase, the logistics were handled efficiently, and the machine appears to be constructed from good quality materials. The service so far has been professional and responsive. Looking forward to starting my brick-making project properly.

Excellent experience overall. The delivery was surprisingly fast, arriving well ahead of the estimated schedule. The packaging was incredibly robust and secure, with no signs of damage whatsoever to the heavy components. Every part was clearly labeled and easy to identify. Regarding quality, the machine feels exceptionally solid and well-constructed. The steel appears to be of high grade, and the welding points are clean and strong. The hydraulic system operates very smoothly with no initial leaks. Customer service was also top-notch; they were prompt and clear in their email communications prior to shipping, confirming all details. A very professional transaction from start to finish. Highly satisfied with the logistical handling and the apparent build quality of the unit itself.

My experience with the shipping was remarkably fast and efficient. The company provided clear tracking information, and the package arrived well ahead of the estimated schedule. Everything was packaged securely with no signs of damage during transit. Regarding the product itself, the build quality feels exceptionally solid and robust. The materials used are clearly high-grade, and the craftsmanship is precise. It has a substantial, durable feel that inspires confidence for long-term use. As for customer service, the support team was outstanding. They were responsive, knowledgeable, and very helpful in answering my pre-purchase questions. Their communication was prompt and professional throughout the entire process. Overall, I am thoroughly impressed and very satisfied with this purchase on all fronts.

Great experience overall with this purchase. The shipping was surprisingly fast and efficient. I was kept well-informed throughout the entire delivery process, which I truly appreciate. The packaging was robust and secure, ensuring the product arrived in perfect condition without any damage. Regarding the quality, it feels solid and well-constructed. The materials used seem durable and capable of handling the intended workload. The service provided by the seller was exceptional. They were responsive, helpful, and professional in all communications, promptly addressing my pre-shipment inquiries. The overall transaction was smooth and hassle-free. I am very satisfied with the entire process from ordering to receiving the item. The attention to detail in both the product preparation and customer interaction was notable. This level of care in logistics and service makes a significant difference. I would certainly consider purchasing from this seller again based on this positive experience. The combination of reliable delivery, apparent product sturdiness, and outstanding support is commendable. It’s refreshing to have such a straightforward and pleasant buying experience.

The delivery was incredibly fast and efficient. I was pleasantly surprised by how quickly the order arrived after placing it. The packaging was secure and protected the item perfectly during transit. There were no delays or issues with the logistics, which made the entire process smooth and worry-free. The quality of the brick maker appears to be excellent based on initial inspection. The materials feel sturdy and well-constructed, promising good durability. The service provided was also outstanding. The support team was responsive and helpful, answering all my questions promptly. Overall, a very positive experience from start to finish. I am highly satisfied with the transaction and would confidently recommend this to others looking for reliable equipment. The combination of speedy delivery, solid build quality, and attentive customer service makes this a great purchase.

The shipping was incredibly fast and well-handled. Took less time than anticipated, and the packaging was secure with no damage whatsoever. Excellent service from the customer support team; they were responsive and helpful throughout the process. The build quality feels sturdy and reliable, with no visible defects. Overall, a very smooth and positive experience from start to finish. Highly recommended for anyone looking for efficient delivery and top-notch support. The product arrived in perfect condition, and the communication was clear and timely. Great job on maintaining high standards in logistics and customer care. I am thoroughly impressed and satisfied with the entire transaction.

Upon receiving the RL2-40 Interlocking Brick Maker, I must express my satisfaction with the overall experience. The delivery was incredibly swift, arriving well ahead of the estimated schedule, which minimized any project delays. Unpacking the machine revealed a robust build and high-quality materials that seem durable and reliable for long-term use. Additionally, the customer service team was exceptionally helpful, promptly addressing my queries with clear and friendly responses. Ultimately, this purchase has been a smooth and positive journey from order to receipt.

Keenly impressed with the overall experience from this purchase. The logistics were handled exceptionally well, with the item arriving ahead of schedule and in perfect condition, which was a pleasant surprise. Quality-wise, the machine appears robust and well-constructed, giving confidence in its durability for long-term use. Customer service was outstanding; the team was responsive and helpful, addressing all my queries promptly and professionally. A truly satisfying transaction that I would highly recommend to others.