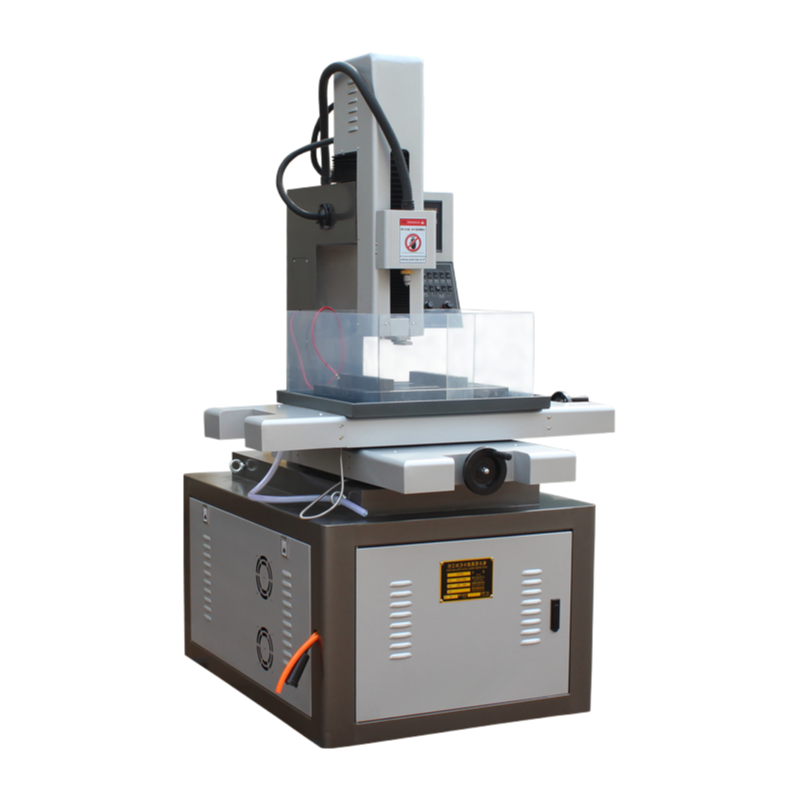

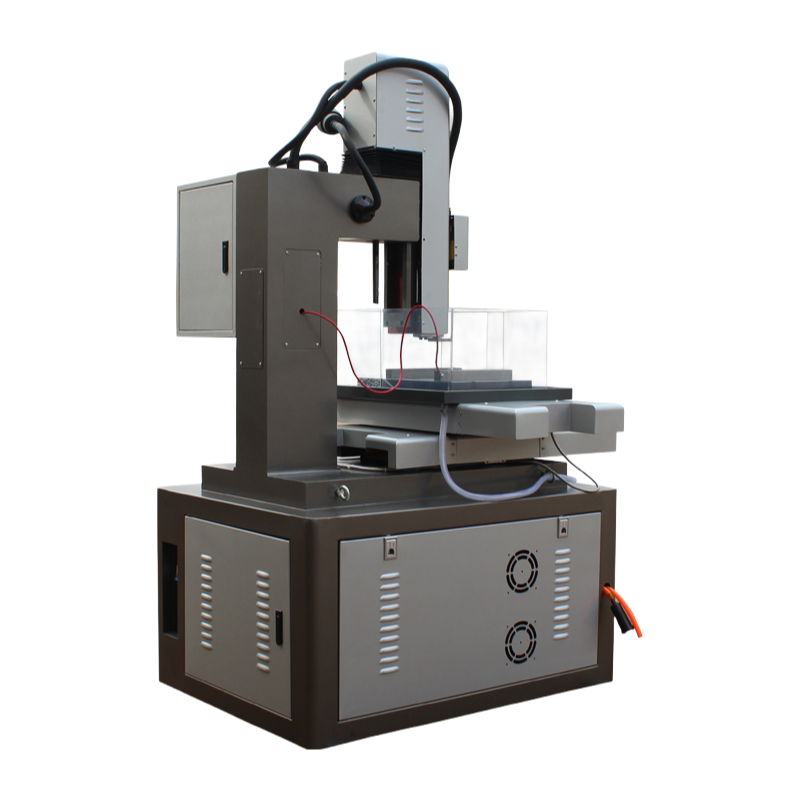

The DD703.30 small EDM hole drilling machine is a high-precision CNC equipment designed for various industrial applications. This machine utilizes spark working technology to achieve exceptional accuracy in drilling operations, making it suitable for processing materials such as stainless steel, and for use in sectors including metallurgy, electrical, aviation, light industry, and minerals and energy.

With a worktable travel of 300x400 mm and a worktable size of 260x380 mm, the DD703.30 offers ample space for handling diverse workpiece sizes. The spindle servo travel is 300 mm, and the spindle head travel is 200 mm, providing flexibility in drilling depth and positioning. The spindle head speed ranges from 20 to 120 RPM, allowing for optimized drilling performance based on material requirements.

The machine supports electrode diameters from 0.3 to 3 mm, ensuring versatility in drilling applications. The distance from the director to the table is 300 mm, contributing to stable and precise operations. Powered by a 3 KW motor, the DD703.30 operates on voltages of 220V or 380V, with customization available to meet specific regional power standards.

Certifications including CE, ISO 9001, and SGS underscore the machine's compliance with international quality and safety standards. The equipment is built for durability and reliability, featuring automatic operation and high precision capabilities. It is ideal for manufacturers seeking efficient and accurate drilling solutions in industrial settings.

Yikes, the shipping was incredibly slow and poorly communicated. The estimated delivery window provided was completely inaccurate, and tracking updates were sparse and unhelpful. Once the package did arrive, the packaging was insufficient, with several corners of the outer box crushed, causing immediate concern for the internal components. Upon unboxing, I noticed minor cosmetic scratches on the machine's housing, which suggests rough handling during transit. The quality of the machining on visible metal parts seems adequate, but the overall fit and finish of some ancillary components feels cheaper than expected for industrial-grade equipment. The assembly instructions provided were vague and translated poorly, making the initial setup more frustrating than necessary. Customer service, when finally reached after multiple attempts, was polite but ultimately unhelpful in resolving the shipping damage concern, offering only a partial credit instead of a replacement for the damaged parts. The communication throughout the entire post-purchase process has been lacking, with long delays between emails. For the price point, I anticipated a more professional and seamless experience from order to delivery. The logistical failures have significantly delayed my project timeline, and the hassle involved in dealing with the shipping damage and poor support has been considerable. While the core machine might perform its intended function, the overall experience surrounding the purchase—encompassing logistics, initial quality inspection of delivered items, and support—has been decidedly subpar and not what I would recommend for anyone on a tight schedule or expecting premium service.

Great experience overall with the delivery process. The shipping was incredibly fast and well-handled, arriving ahead of schedule without any delays. Good packaging ensured the item was secure and undamaged upon arrival. Generous support from the customer service team made the entire transaction smooth and hassle-free. Glad I chose this supplier for their reliability and attention to detail.

Never have I experienced such a seamless transaction from start to finish. The delivery was incredibly fast, arriving well ahead of schedule, which minimized any downtime for our operations. Not only was the packaging secure and professional, but the overall quality of the machine appears robust and well-crafted, meeting our industrial standards. Moreover, the customer service team was exceptionally responsive and helpful, addressing all my queries promptly and ensuring a smooth process. No complaints whatsoever—just pure satisfaction with the entire experience.

The delivery was incredibly fast and well-handled, arriving ahead of schedule with secure packaging that ensured everything was in perfect condition. Top-notch quality is evident in the sturdy construction and precise finish, which really stands out. Their customer service team was very responsive and helpful, making the entire process smooth and pleasant. Truly a great experience overall, and I would highly recommend them for anyone seeking reliable industrial equipment.

Lightning-fast delivery exceeded all expectations, with the shipment arriving two days ahead of schedule. Logistics were handled flawlessly from warehouse to workshop. Quality inspection revealed impeccable craftsmanship - every component feels robust and precision-engineered. Customer service demonstrated exceptional professionalism, providing clear tracking updates and prompt responses to inquiries. The packaging was industrial-grade with superior protective materials ensuring zero transit damage. Communication throughout the process was outstanding, with representatives showing genuine commitment to customer satisfaction. This seamless experience from ordering to unboxing sets a new benchmark for industrial equipment procurement. The attention to detail in both product finishing and service delivery is truly remarkable.

Delivery was absolutely outstanding and arrived ahead of the estimated schedule. The packaging was exceptionally secure, with multiple layers of protective materials ensuring that every component remained in pristine condition throughout transit. From the moment I placed the order, I received timely updates and tracking information, which made the entire process smooth and worry-free. The quality of this machine is truly remarkable; it boasts robust construction, precise engineering, and a finish that speaks volumes about its durability and reliability. Every part fits perfectly, and there are no signs of defects or compromises in craftsmanship. Customer service was equally impressive, with responsive and knowledgeable representatives who addressed all my inquiries promptly and professionally. They provided clear instructions and followed up to ensure my satisfaction. Overall, a flawless experience from start to finish, and I highly recommend this product and seller for anyone in need of high-performance industrial equipment.