The industrial plate pasteurization system is designed for efficient heat treatment of various liquid products including fresh milk, dairy beverages, juices, tea and alcoholic drinks. This equipment is particularly suitable for processing heat-sensitive liquids while maintaining product quality.

The processing parameters are precisely controlled with product inlet temperature at 5°C, homogenizing at 65°C, sterilizing at 85-95°C with 15-second temperature holding, and final product outlet temperature at 5°C. This ensures optimal pasteurization while preserving product characteristics.

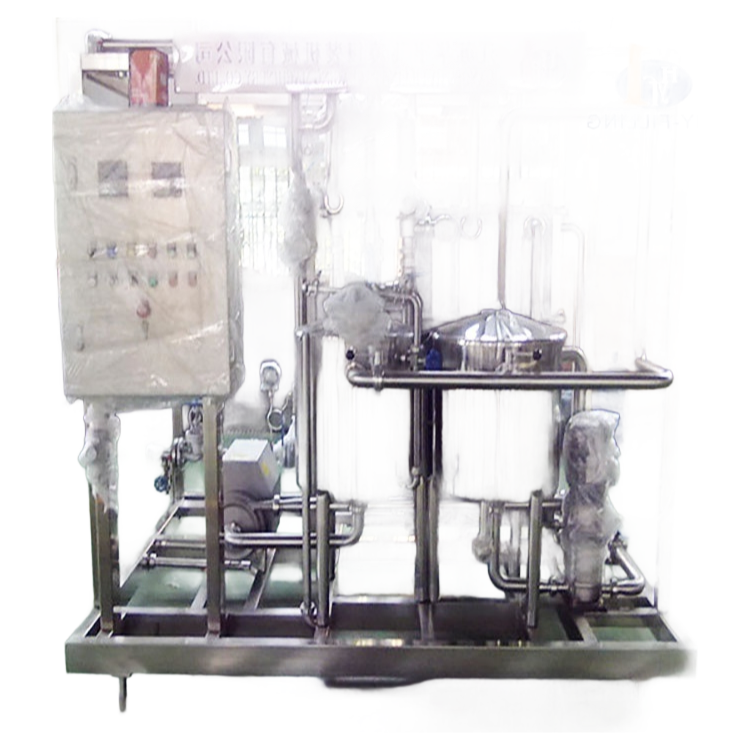

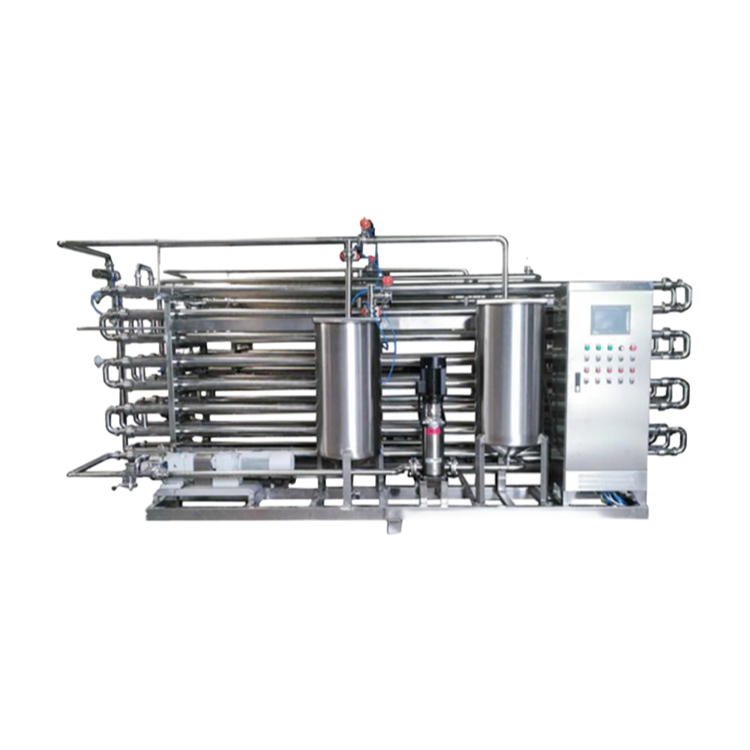

This full-automatic dual purpose system features a multi-stage plate heat exchanger configuration with balance tank, sanitary pumps, hot water tank and automatic control valves. The total power consumption is 13kW with maximum steam consumption of 330kg/h.

Key advantages include high heat exchange efficiency with less than 1.0°C temperature difference during heating, preventing milk browning while achieving over 90% heat recovery rate. The system maintains pasteurization temperature accuracy within ±0.5°C through proportional control valves.

The equipment incorporates several technological improvements including faster temperature rise during sterilization and CIP stages, reducing processing preparation time. The built-in CIP system automatically adds acid/alkaline solutions and executes cleaning programs for efficient sanitation.

Operation is managed through a PLC control system with touch screen interface and temperature recording capability. The standard configuration includes plate heat exchanger, material balance tank, hot water system, product pumps, steam/water mixer and stainless steel piping.

Production capacity ranges from 500L to 20T per hour, with mechanical components and processing parameters customizable to specific customer requirements. The system is constructed from food-grade SUS304/SUS316 stainless steel for durability and hygiene.

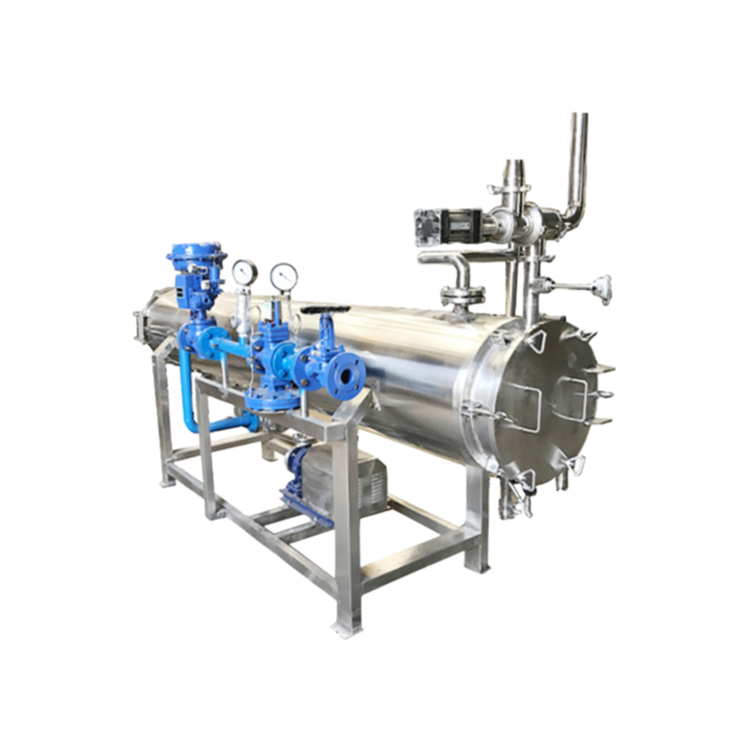

Additional optional equipment includes RO water treatment systems for pure water production and various packaging solutions including blow molding, labeling and shrink wrapping machines for complete production line integration.