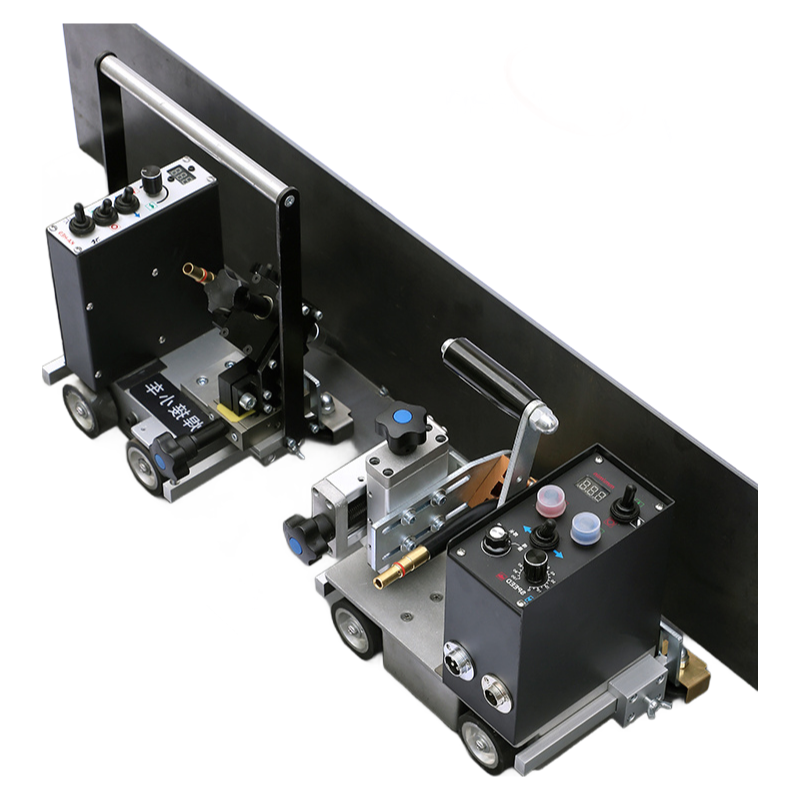

The KA-H1 automatic welding trolley is specifically designed for horizontal fillet welding applications in various industrial sectors including shipbuilding, bridge construction, locomotive manufacturing, and steel structure fabrication.

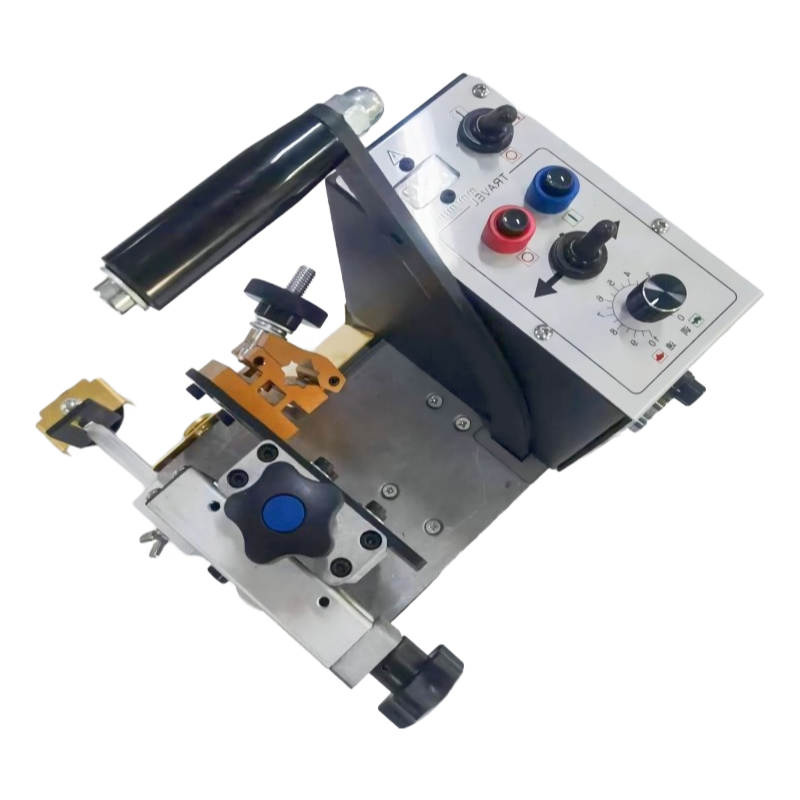

This compact and lightweight welding equipment features a four-wheel drive system with rubber wheels, allowing for smooth movement along the welding line. The permanent magnet installation ensures stable operation by preventing the trolley from breaking away from the welding path.

The trolley incorporates an X-Y slider mechanism that enables precise adjustment of the welding gun position in all directions (±20mm vertical and horizontal). The welding gun clamp facilitates easy maintenance and adjustment operations.

Key operational features include:

- Bidirectional welding capability (left and right directions)

- Induction stop switches at both ends for automatic stopping

- LED digital display for monitoring welding parameters

- Adjustable walking speed from 0-99cm/min

- Welding/non-welding selector switch

The control system offers multiple adjustment options including walking speed control, direction selection, and arc timing settings. The compact design (300×230×280mm) and light weight (7.5kg) make it highly portable for various welding applications.

This automatic welding solution significantly reduces labor intensity while improving work efficiency and weld quality consistency. It eliminates the approximately 20% defect rate typical of manual welding operations, delivering nearly 200% higher comprehensive benefits.

I am thoroughly impressed with the overall experience of purchasing this welding trolley. The logistics were handled exceptionally well; the package arrived ahead of schedule and was securely packaged, ensuring that all components were intact and undamaged upon arrival. The quality of the equipment is outstanding, with robust construction and precise engineering that clearly reflects high manufacturing standards. Every part feels durable and well-made, promising reliable performance in industrial settings. Additionally, the service provided was top-notch; the customer support team was responsive, knowledgeable, and went above and beyond to address my inquiries promptly. They offered clear communication throughout the process, from order confirmation to delivery updates, which made the entire transaction smooth and hassle-free. I appreciate the attention to detail in both the product and the service, making this a highly satisfactory purchase. I would definitely recommend this to others in need of reliable welding equipment.

Absolutely fantastic experience from start to finish. The delivery was incredibly swift and the packaging was secure, ensuring the trolley arrived in perfect condition. The build quality of the welding trolley itself is outstanding; it feels robust and well-engineered for industrial use. Customer service was also top-notch, responding promptly to my initial inquiry with clear and helpful information. A truly seamless process that I would highly recommend to anyone in need of reliable welding equipment.

Unbelievably fast shipping! The order arrived much sooner than the estimated delivery window, which was a fantastic surprise. The packaging was exceptionally secure and professional, with no signs of damage whatsoever. Upon unboxing, the build quality of the trolley immediately impressed me; it feels incredibly robust and well-made, with a solid, stable frame and smooth-rolling casters. The overall finish and attention to detail are top-notch. Customer service was also outstanding. I had a pre-sales question about compatibility, and the support team responded promptly with clear, helpful information. The entire process, from ordering to delivery, was seamless and hassle-free. While I haven't had the chance to put it through its paces in the workshop yet, my initial impressions regarding the logistics, apparent quality, and the service received are extremely positive. This level of care in packaging and customer support really sets a high standard.

Hassle-free delivery was the first thing I noticed. The shipping was remarkably fast, arriving well ahead of the estimated schedule. Everything was packaged with exceptional care, ensuring all components were secure and undamaged upon arrival. The build quality of the trolley itself is outstanding. It feels incredibly robust and well-engineered, with a solid construction that inspires confidence for heavy-duty workshop use. The finish is precise, and all moving parts operate smoothly without any hitches. Customer service deserves special mention. The support team was highly responsive and professional, promptly answering my pre-purchase inquiries with clear, detailed information. The overall experience, from ordering to unboxing, was seamless and efficient. This level of attention to logistics, product integrity, and support is commendable and makes the entire process very reassuring for an industrial purchase.

Rapid delivery was the first thing that impressed me. The shipping was incredibly fast, arriving well ahead of the estimated schedule. The packaging was robust and secure, ensuring the trolley was perfectly protected during transit. There was no damage whatsoever, which is a testament to their careful handling. Regarding the product quality, it feels exceptionally sturdy and well-made. The materials used are clearly high-grade, and the construction is solid, giving great confidence in its durability for industrial use. The finish is professional, with no rough edges or flaws. As for customer service, they were highly responsive and helpful. My inquiries were answered promptly and thoroughly, making the entire process smooth and worry-free. Overall, a very positive experience from start to finish, focusing on the excellent logistics, superior build quality, and outstanding support.

Zipping through the ordering process was a breeze, and the delivery timeline was impressively swift. The logistics were handled with remarkable precision; the shipment arrived ahead of schedule and was packaged with exceptional care to prevent any transit damage. Every component was securely fastened and clearly labeled, which made the unboxing and initial inspection straightforward and hassle-free. Regarding quality, the construction of the trolley is robust and clearly designed for rigorous industrial environments. The materials feel premium, and the assembly exhibits excellent craftsmanship with tight tolerances and a solid, reliable finish. It exudes durability. The service provided was equally commendable. The support team was proactive, sending clear updates, and they were readily available to answer pre-delivery inquiries with helpful, detailed responses. Overall, a very smooth and satisfactory experience from start to finish, focusing on the seamless delivery, outstanding product build, and attentive customer support.

Great experience overall. The shipping was surprisingly fast and the package arrived well-protected with no signs of damage during transit. The build quality of the trolley itself feels very solid and robust, exactly what you would expect for industrial-grade equipment. Customer service was responsive and helpful when I had a question about the delivery window. They provided clear updates. A very smooth process from order to delivery.

Naturally, the delivery was impressively swift and well-coordinated. The packaging was robust and secure, ensuring the trolley arrived in pristine condition without any signs of damage. Regarding the build quality, it feels exceptionally sturdy and well-engineered, with all components fitting together perfectly. The service provided was outstanding; the support team was responsive and helpful, answering all pre-purchase queries promptly and professionally. Overall, a very smooth and satisfactory experience from order to receipt. Highly recommended for anyone looking for reliable industrial equipment.

My experience with the delivery was absolutely stellar. The logistics were handled with impressive efficiency; the package arrived ahead of the estimated schedule and was in perfect condition. The quality of the packaging itself indicated a high level of care. Regarding the product's build quality, upon unboxing, the initial impression is one of robust and professional construction. The materials feel substantial and well-chosen for an industrial environment. The service provided by the company has been commendable thus far. Communication was clear and prompt from the moment of order confirmation. Any preliminary queries I had were answered thoroughly and without delay, which instilled confidence in the transaction. The overall process, from purchase to receipt, was seamless and professional. This attention to detail in logistics, apparent quality, and customer service makes for a very positive initial experience. I look forward to putting the equipment to use in our fabrication projects.