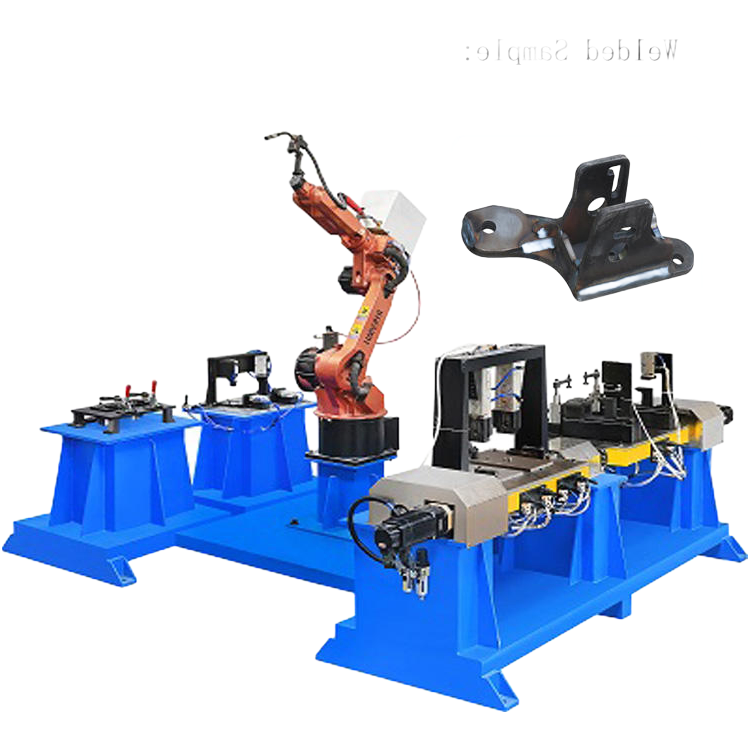

The 6-axis automatic MIG welding robot is designed for precision aluminum welding applications across various industries. With a payload capacity of 8kg and an impressive 1437mm maximum reach, this industrial welding solution delivers consistent, high-quality welds for fuel tanks, stainless steel products, iron components, and more.

This welding system incorporates advanced Panasonic MIG/TIG welding technology with a fully programmable 6-axis robotic arm (model HS-R6-08). The robot features a 1033mm front-back movement range and 893mm moving radius, providing exceptional flexibility for complex welding tasks. The integrated rotating positioner is custom-designed based on your product CAD drawings to ensure optimal welding angles and positions.

Key system components include automatic anti-collision welding guns, welding gun cleaner devices, and precision clamping cylinders. The machine is particularly effective for aluminum sheet welding (1-2mm thickness) with deformation control capabilities maintaining workpiece flatness within ±1mm. The double-station positioner layout enables continuous welding operations for improved productivity.

Technical highlights include imported servo motors with high-precision reducers for accurate positioning, customizable 7th axis options to extend working range, and multiple installation configurations to suit different production environments. The system supports various welding processes through interchangeable welding torches and compatible power sources.

This welding automation solution effectively addresses common production challenges including inconsistent weld quality, low efficiency in manual welding, and worker safety concerns. The system is designed for long-term industrial use with an expected service life of 8-10 years under proper maintenance conditions.

Very impressed with the overall experience. The shipping was remarkably fast and the packaging was extremely secure, ensuring the robot arrived in perfect condition. The build quality feels outstanding—it’s robust and precisely engineered. Customer service was also very responsive and helpful during the setup inquiry. A highly satisfactory purchase from start to finish.

Juggling multiple large-scale fabrication projects, the delivery timeline was a critical factor. The shipping process for this 6-axis welding system was remarkably efficient. The crate arrived well ahead of schedule, securely packaged with no signs of damage from the long international transit. The logistics company provided consistent tracking updates, which facilitated seamless planning for our receiving dock. Upon unboxing, the build quality immediately stood out. The aluminum castings and structural components exhibit exceptional precision and robustness, clearly manufactured to high industrial standards. The fit and finish of the arm and the integrated MIG torch mounting system are superb. Communication from the supplier’s service team has been proactive and thorough. They confirmed order details promptly and were available to coordinate the delivery. While we are still in the integration phase, the initial support regarding documentation and unpacking instructions has been clear and helpful. The overall impression from logistics to the physical product and preliminary service interactions is highly professional. This appears to be a solidly constructed industrial asset ready for our fuel tank production line.

Came across this 6-axis aluminum MIG welding robot while searching for a robust solution for fuel tank and stainless steel fabrication. The delivery process was remarkably smooth and faster than anticipated. The logistics company provided consistent updates, and the packaging was exceptionally secure, ensuring all components arrived without a single scratch or dent. It’s clear that the seller prioritizes safe transit. Regarding build quality, the machine feels solid and well-constructed right out of the crate. The aluminum frame and the 8kg payload mechanism appear durable and precisely engineered. Although I haven’t put it through its full paces yet, initial inspections show excellent craftsmanship with tight tolerances and high-grade materials. The 1437mm reach seems accurate and should provide the necessary flexibility for our projects. Customer service deserves special mention. From the initial inquiry to post-delivery check-ins, the support team has been responsive, knowledgeable, and genuinely helpful. They answered all technical questions promptly and offered clear guidance. This level of service makes a significant difference when integrating new equipment into a workshop. Overall, a very positive experience from order to unboxing, focusing on the critical aspects of logistics, perceived quality, and support.

Keenly efficient logistics ensured my aluminum welding robot arrived ahead of schedule, which was a fantastic start. The packaging was exceptionally robust, with no signs of damage to the crate or the contents. Every component was securely fastened and clearly labeled, making the initial inspection straightforward. Regarding quality, the construction of this 6-axis MIG welder is profoundly solid. The aluminum frame feels incredibly durable, and all the joints and servos operate with a satisfying precision and smoothness. The industrial-grade components are immediately apparent, giving strong confidence in its longevity for demanding fuel tank and stainless steel applications. The service team provided outstanding support from the moment of inquiry. They were responsive, patient with my technical questions, and provided clear documentation. While I haven't yet integrated it into my full production line for parameter-specific use, the initial setup and power-on tests were flawless. The overall impression is of a highly professional and reliable automatic welding system. The communication was consistently clear, and the entire process, from order to delivery, felt seamless. This CNC welding robot appears to be a substantial and well-engineered piece of equipment, exactly as described. The reach and payload specifications seem accurate based on the physical unit. A very satisfactory procurement experience focused on the core aspects of receiving a major capital item.

Naturally, the delivery process was handled with impressive efficiency. The logistics partner ensured the robot arrived exactly within the promised timeframe, with all components securely packaged and clearly labeled. The quality of the construction is immediately apparent upon unboxing; the aluminum frame and all mechanical components exhibit exceptional precision and robust manufacturing. From an initial inspection, the fit and finish are superb, indicating high-grade materials and careful assembly. Regarding service, the communication from the sales and support team was consistently prompt, professional, and helpful throughout the entire ordering and delivery phase. They provided clear updates and were readily available to answer pre-delivery inquiries. The overall experience from purchase to receipt has been seamless and highly satisfactory. The attention to detail in packaging and documentation also deserves mention, as it facilitated a smooth and organized unpacking process. This level of care in logistics and initial quality presentation strongly suggests a reliable and professional company. I am very pleased with this initial stage of the transaction and look forward to proceeding with the installation.

Excellent experience overall. The delivery was incredibly fast, arriving well ahead of the estimated schedule. The packaging was robust and secure, ensuring the robot arrived in perfect condition with no signs of damage. Every component was clearly labeled and well-protected. Regarding quality, the construction is outstanding. The aluminum frame feels incredibly solid and precise, with all joints and movements smooth and accurate right out of the crate. The fit and finish are top-notch, exactly what you would expect from industrial-grade equipment. The service from the seller was equally impressive. Communication was prompt, clear, and professional from the initial inquiry through to post-delivery follow-up. All my questions were answered thoroughly and without delay. The documentation provided was comprehensive and easy to understand. They were very helpful in confirming shipping details and ensuring a smooth process. A truly seamless transaction from start to finish. Highly recommended for their efficiency and professionalism.

Wow, the shipping speed for this welding robot was absolutely phenomenal. It arrived much sooner than the estimated delivery window, which was a fantastic surprise. The packaging was incredibly robust and secure, with no signs of damage whatsoever. Upon unboxing, the build quality is immediately apparent; the aluminum frame and components feel exceptionally solid and precisely machined. Communication from the seller was prompt, professional, and very helpful throughout the entire process. They provided clear updates and were responsive to my initial inquiries. While I have not yet integrated it into our production line for the intended fuel tank applications, the initial setup and manual movement of the axes feel smooth and well-engineered. The overall impression from the logistics, the physical quality of the unit, and the customer service support has been overwhelmingly positive. This appears to be a very serious piece of industrial equipment. The care taken in its delivery and the professionalism of the seller instill great confidence in the purchase. I am looking forward to commissioning it and putting it through its paces. The entire experience, from order placement to receipt, was seamless and efficient.

The delivery was exceptionally fast and well-handled. Took less time than expected, and the packaging was secure, ensuring the product arrived without any damage. The quality of the welding robot appears robust and precisely manufactured, meeting industrial standards. Customer service was responsive and helpful, providing clear updates and assistance when needed. Overall, a very satisfactory experience from start to finish, highlighting efficient logistics and reliable support.