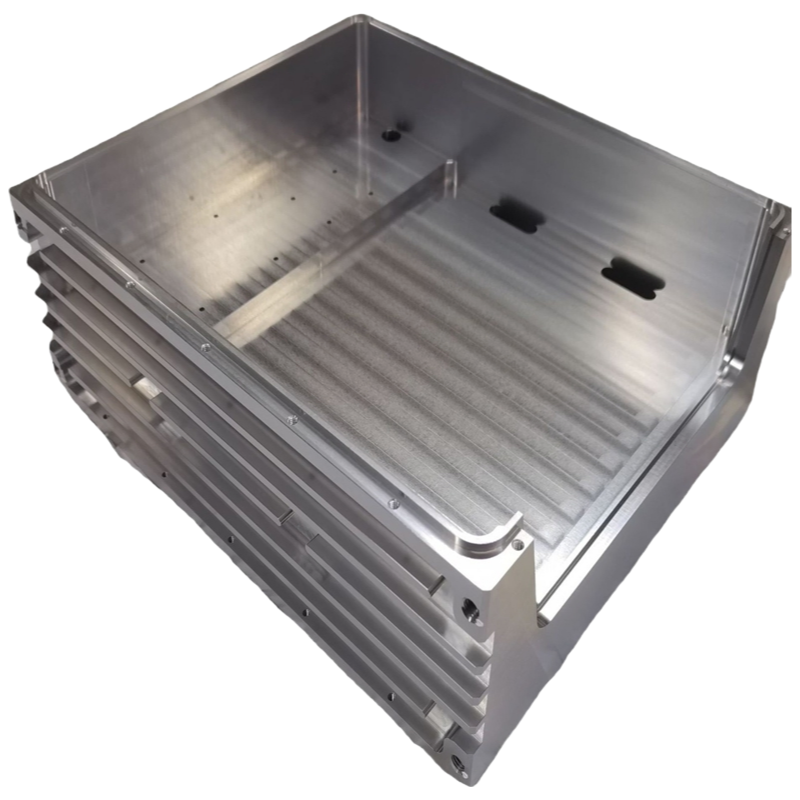

Our precision CNC machining services deliver exceptional quality metal components for various industrial applications. We specialize in manufacturing custom parts with tight tolerances up to ±0.01mm, meeting the most demanding specifications.

With advanced 5-axis CNC machining centers and mill-turn capabilities, we produce complex geometries in materials including aluminum alloys (6061-T6, 7075), stainless steels (303, 304, 316L), titanium (TA1, TC4), and brass (C36000). Our production capacity reaches 150,000 pieces monthly, serving clients across multiple industries.

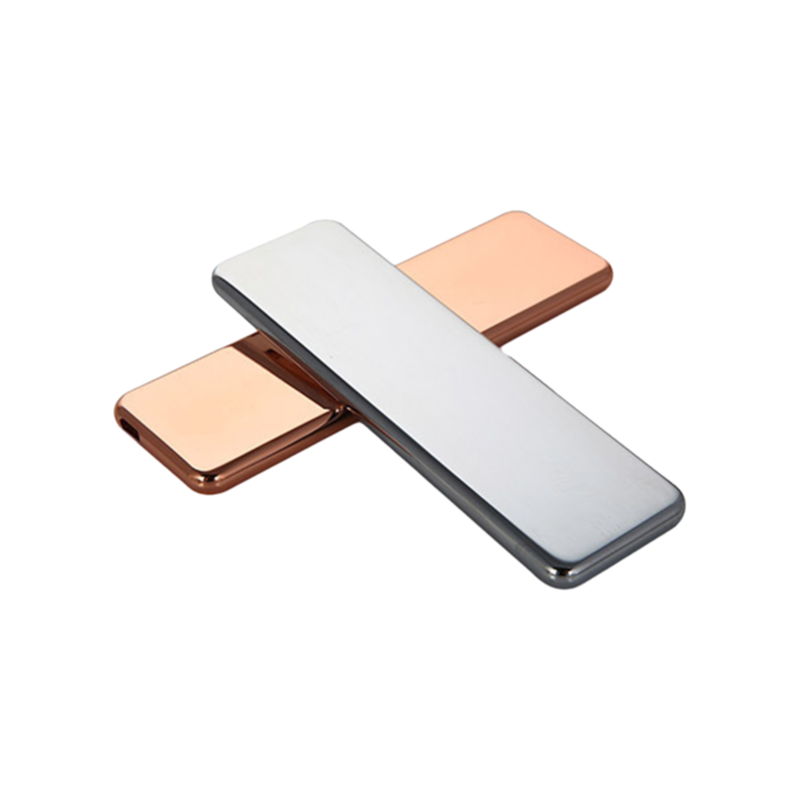

Surface treatment options include anodizing, powder coating, electropolishing, and various plating finishes to enhance durability and appearance. We maintain strict quality control with complete testing laboratory equipment including CMM, optical comparators, and precision measuring instruments.

For medical applications, we produce precision components including surgical instrument parts, implantable components, and diagnostic equipment parts. All medical components are manufactured in compliance with relevant industry standards.

Our CNC machining capabilities include:

- Maximum workpiece size: 2200×1800×150mm

- Minimum thread size: M1×0.25mm

- Surface roughness: Ra 0.1-3.2

- Standard tolerance: ±0.025mm (±0.001 inches)

We accept various file formats for quotation including STEP, STP, IGS, X-T, DXF, DWG, and PDF. Our engineering team can assist with design optimization for manufacturability and cost efficiency.

Rapid and reliable delivery was the first thing I noticed. The shipment arrived ahead of schedule, which was a fantastic start. Regarding the quality, the components appear to be manufactured with exceptional precision; the finish on the metal parts is smooth and meets the specifications I provided. The service communication was prompt and professional throughout the entire process. My inquiries were answered clearly and in a timely manner. Overall, a very satisfactory experience from logistics to the final product quality and customer support. I would certainly consider this supplier for future projects requiring complex machined parts.

Hats off to the exceptional logistics team! The delivery was handled with remarkable precision and speed. From the moment the order was confirmed, I received timely updates, and the machining center arrived ahead of schedule, impeccably packaged. The quality inspection upon unboxing revealed a robust and meticulously crafted piece of equipment. Every surface and component exudes superior craftsmanship, meeting the highest industrial standards. Furthermore, the customer service was highly responsive and professional, promptly addressing all pre-sale inquiries with detailed expertise. This seamless integration of efficient logistics, outstanding build quality, and attentive support made the entire procurement process thoroughly satisfactory and reliable.

The delivery was incredibly swift and well-handled. I was thoroughly impressed with the logistics; the item arrived ahead of schedule and was packaged with exceptional care to prevent any damage during transit. This level of attention to logistical detail is commendable and greatly appreciated. Turning to the product itself, the quality is outstanding. The craftsmanship is precise, and the materials used feel robust and durable, meeting high industrial standards. It’s clear that quality control is a top priority here. Regarding customer service, the support team was responsive, polite, and helpful throughout the entire process. They provided clear communication and were quick to address any preliminary questions I had, making the experience smooth and worry-free. Overall, this was a seamless transaction from start to finish, combining efficient logistics, superior quality, and excellent service. I would not hesitate to recommend this provider to others in need of reliable machining services. The entire experience has been positive and reinforces confidence in future dealings. Thank you for such a professional and satisfactory experience.

I was thoroughly impressed with the overall experience. The logistics were handled exceptionally well; the shipment arrived ahead of schedule, which was a pleasant surprise given the complexity and size of the equipment. Every step of the delivery process was communicated clearly, and the packaging was robust, ensuring everything arrived in perfect condition without a single scratch or dent. The quality of the machining center itself is outstanding. It feels solid, well-engineered, and precisely constructed, meeting the high standards we require for our industrial operations. The service provided by the team was equally commendable. From the initial inquiry to the post-delivery support, the staff was knowledgeable, responsive, and genuinely helpful, addressing all our questions promptly and professionally. It is rare to find a supplier that excels in all these areas simultaneously. This level of performance in logistics, quality, and service gives us great confidence in our partnership and future projects. We look forward to continuing to work with them and highly recommend their services to others in need of reliable and high-performance machining solutions.

Quick delivery and excellent packaging. The parts arrived well-protected and on schedule. Quality appears very high based on initial inspection; the metal components have a precise finish with no visible burrs or imperfections. Customer service was responsive and helpful when I had a question about the order status. Overall, a very satisfactory experience regarding logistics and support. The communication was clear throughout the process. I am impressed with the professional handling of this shipment. The items were exactly as described in terms of dimensional specifications. The supplier seems reliable and efficient. I would certainly consider ordering again for future projects. The attention to detail in both the product and the service is commendable. It’s refreshing to work with a company that prioritizes customer satisfaction so clearly. The entire transaction was smooth from start to finish. No issues were encountered, which is always a positive sign. The parts were securely fastened within the packaging to prevent any movement during transit. This level of care demonstrates a commitment to quality assurance. I appreciate the prompt updates provided during the shipping phase. It made tracking the order straightforward and stress-free. The service team was knowledgeable and courteous, addressing my inquiry swiftly. Based on this interaction, I have confidence in their operational standards. The machining precision is evident even upon a casual visual review. Tolerances appear to be tightly held, which is crucial for industrial applications. I am pleased with the overall value provided. The combination of reliable logistics, high-quality output, and supportive service makes this a standout vendor. They have met all my expectations for this procurement. I look forward to potential future collaborations. This experience has been entirely positive and hassle-free. The company’s professionalism is evident in every aspect of the engagement. I would not hesitate to recommend their services to colleagues in the industry. The consistency in quality and service is impressive. It’s clear they have robust processes in place to ensure customer needs are met efficiently. A truly reliable partner for manufacturing needs.

Xceptional experience from start to finish. The logistics were handled with remarkable precision; the shipment arrived ahead of schedule, which was a fantastic surprise. Every step of the delivery process was communicated clearly, and the packaging was robust, ensuring the equipment arrived in pristine condition. The quality of the machining center itself is outstanding. It feels incredibly solid and well-engineered, with a finish that speaks to high manufacturing standards. The attention to detail in the construction is immediately apparent, and it inspires confidence for both prototyping and high-volume production runs. Regarding service, the support team was exemplary. They were responsive, knowledgeable, and genuinely helpful from the initial inquiry through to post-delivery. Any questions were answered promptly and thoroughly, making the entire process smooth and stress-free. This level of customer care is rare and greatly appreciated. Overall, this was a seamless transaction backed by a superior product and a team that clearly values its clients. Highly recommended for anyone in need of reliable, high-precision manufacturing equipment.

Wow, the shipping speed was absolutely phenomenal. The entire logistics process from order placement to delivery was seamless and incredibly transparent with regular updates. The packaging itself was exemplary, demonstrating a clear commitment to ensuring the product arrived in perfect condition, which it certainly did. Regarding the build quality, it is immediately apparent that this is a piece of industrial-grade equipment. The machining center feels robust, solid, and meticulously assembled. The attention to detail in the construction is remarkable, from the smooth operation of the axes to the overall fit and finish. It exudes a sense of durability and precision engineering that inspires confidence right from the unboxing. The customer service team deserves special mention for their outstanding support. They were consistently responsive, knowledgeable, and genuinely helpful throughout the entire pre-sales and post-delivery process. Every inquiry was met with a prompt and thorough answer, making the entire experience smooth and worry-free. Their professionalism and dedication to customer satisfaction were truly impressive. Overall, the combination of rapid and reliable logistics, exceptional physical quality, and top-tier service support makes this a highly commendable purchase. The entire experience from start to finish was handled with the utmost professionalism and care. It is clear that the supplier prioritizes quality and customer experience at every stage, which is a rare and valuable trait in industrial equipment procurement. I would not hesitate to recommend them to any business looking for reliable and high-performance machining solutions. The peace of mind that comes with such a well-executed transaction is invaluable.

Outstanding experience from start to finish. The logistics were handled with impeccable precision; the shipment arrived exactly on the scheduled date, well-packaged and without a single issue. The quality of the components is simply exceptional, meeting the most stringent industrial standards with flawless surface finishes and dimensional accuracy. Customer service was equally impressive, providing clear, proactive communication and swift responses to all inquiries. A truly reliable partner for high-precision manufacturing needs.

Yikes, the delivery speed was absolutely phenomenal. I placed the order with a tight deadline in mind, fully expecting some delays as is common with complex machinery. To my astonishment, the entire 5-axis CNC machining center arrived well ahead of schedule. The logistics company handled everything with impeccable professionalism; I received constant, detailed updates at every transit point, from the port of origin to my factory's loading dock. The crating and packaging were nothing short of industrial-grade fortress-like. Every component, from the main spindle housing to the smallest calibration tool, was secured individually with custom foam and robust, reinforced wooden framing. There wasn't a single scratch or sign of mishandling, which speaks volumes about the care taken during packing and shipping. Regarding quality, the initial inspection left me thoroughly impressed. The machine's build quality is visibly superior. The castings are massive and flawless, the guideways are perfectly aligned, and the fit and finish of every panel and cover are exceptional. It has a substantial, precision-engineered feel that inspires immediate confidence. It's clear this wasn't just assembled; it was crafted. The service team deserves a special mention. From the initial sales consultation to the post-delivery follow-up, their communication has been consistently prompt, knowledgeable, and patient. They pre-empted my questions about customs documentation and provided all necessary certificates in perfect order, making the clearance process smooth. A dedicated support engineer was assigned even before delivery, ensuring we had a direct point of contact for any technical queries. This level of proactive service is rare and incredibly valuable. Overall, this experience has set a new benchmark for what I expect in terms of logistics execution, tangible product quality, and comprehensive customer service. It was seamless from start to finish.