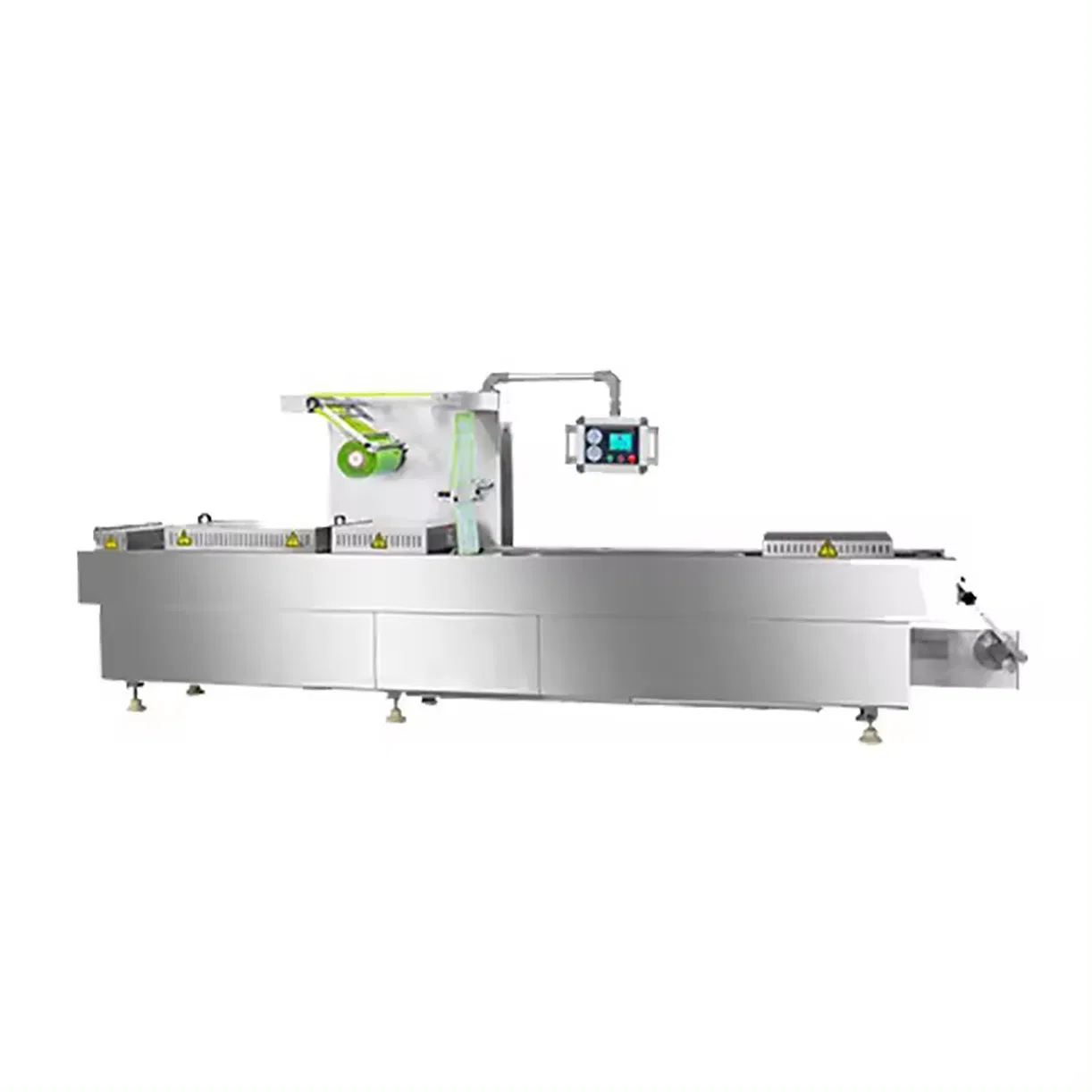

The stretch film vacuum packaging machine utilizes advanced thermoforming technology to create hygienic, extended-shelf-life packaging solutions. The process begins with heating and stretching the bottom film into mold shapes, followed by product loading, film covering, vacuum sealing, and final separation into individual packages.

Key advantages include superior hygiene through vacuum sealing and optional Modified Atmosphere Packaging (MAP) technology, which significantly extends product shelf life. The rectangular packaging format enables efficient stacking for storage and transportation, while transparent film allows for product visibility.

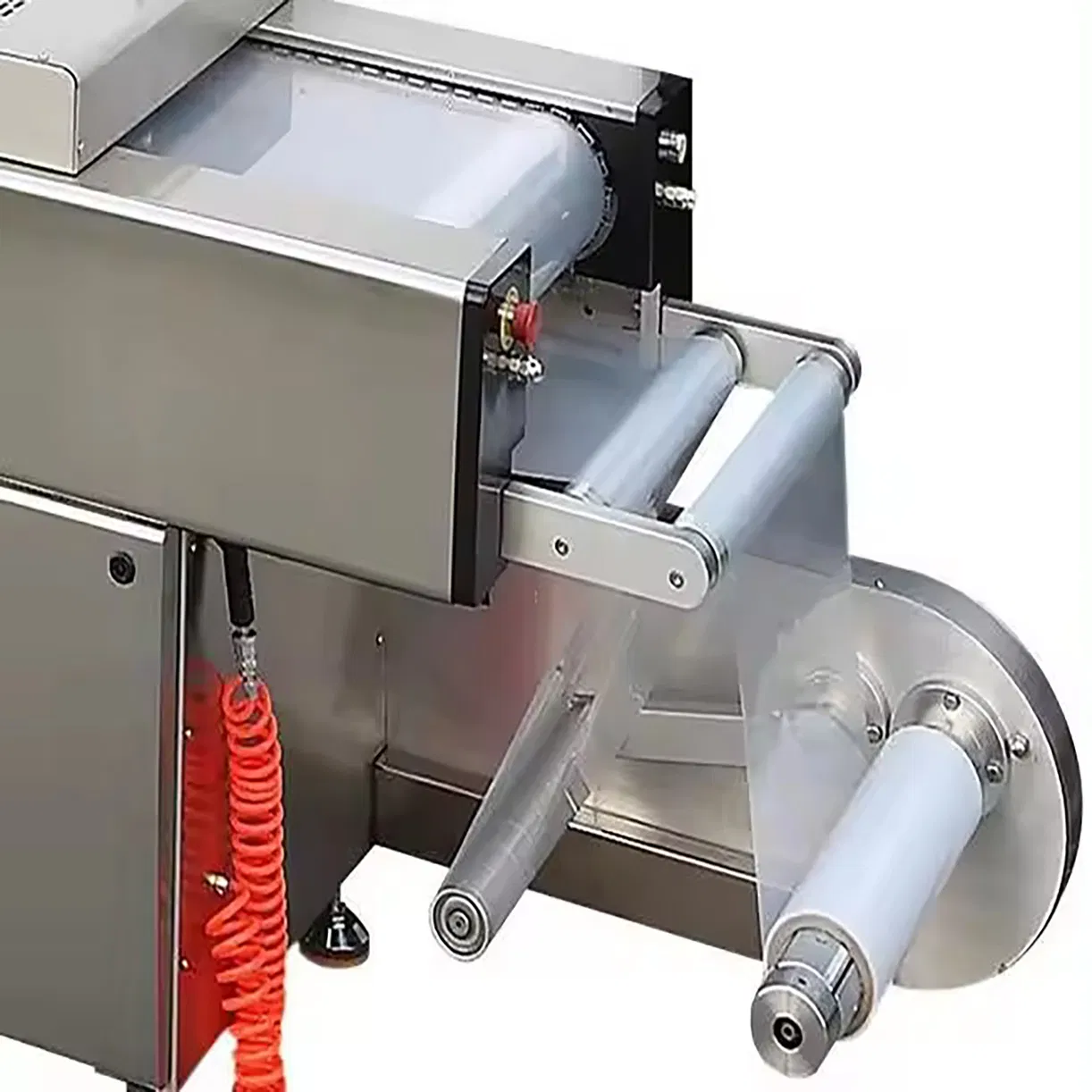

The machine features a 10" PLC touch screen for complete operational control and incorporates multiple safety sensors that automatically stop operation when covers are opened. Custom forming dies can be substituted to accommodate different product sizes and shapes within the machine's forming dimensions.

Special design elements include easy-tear corners for convenient package opening and various forming options to suit different product requirements. The 304 food-grade stainless steel construction ensures durability and meets hygiene standards for food processing applications.

Delivery was incredibly fast and efficient, arriving well ahead of schedule without any delays or damages. The packaging was secure and professional, ensuring the item was protected throughout transit. Quality-wise, the construction feels robust and durable, with excellent materials that promise long-term reliability. Customer service was outstanding, providing prompt and helpful responses to all my inquiries, making the entire process smooth and hassle-free. Overall, a fantastic experience from start to finish.

The shipping was incredibly fast and well-handled, arriving ahead of schedule without any damage. The product's build quality feels robust and durable, showing excellent craftsmanship. Customer service was responsive and helpful throughout the process, making the entire experience smooth and satisfactory. I'm thoroughly impressed by the attention to detail in both the packaging and the machine itself. Everything was securely wrapped, and the instructions were clear and easy to follow. The team went above and beyond to ensure I had all the information I needed. Overall, a top-notch experience from start to finish, and I would highly recommend this to others looking for reliable equipment. The communication was prompt, and any queries I had were addressed quickly and professionally. It's rare to find such a seamless combination of speed, quality, and support in one package.

Highly impressed with the delivery speed of this packaging system—it arrived much faster than expected, which was a pleasant surprise. The packaging was secure and intact, showing no signs of damage during transit. As for quality, the machine feels robust and well-built, with durable materials that seem capable of handling heavy industrial use. The service team was exceptional, providing clear communication and prompt responses to my inquiries, making the entire process smooth and hassle-free. Overall, a reliable purchase that met my expectations in logistics, build, and support.

Completely satisfied with the delivery speed; the shipment arrived ahead of schedule without any delays. The build quality feels robust and durable, holding up well in our industrial setting. Customer support was exceptional, providing prompt and helpful assistance whenever needed. Overall, a reliable and efficient experience from start to finish.

Highly impressed with the overall experience! The shipping was incredibly fast and reliable, with the item arriving well-packaged and ahead of schedule. The quality of the packaging materials used for transit was excellent, ensuring everything arrived in perfect condition. Customer service was outstanding—they were responsive, helpful, and went above and beyond to address my inquiries promptly. I'm thoroughly satisfied and would definitely recommend this to others.

Outstanding experience from start to finish! The delivery was incredibly fast, arriving well ahead of the estimated date, which was a pleasant surprise. The packaging was secure and professional, ensuring everything arrived in perfect condition. As for the quality, the machine feels robust and well-constructed, with no visible defects or issues upon inspection. The service team was exceptional—they provided clear communication throughout the process and were quick to answer any questions I had. Overall, I'm thoroughly impressed with the efficiency and care demonstrated in every aspect of this transaction. Highly recommended for anyone seeking reliable equipment with top-notch support.

Beyond expectations in every aspect! The logistics were handled impeccably; the shipment arrived ahead of schedule, well-packaged and without any damage. Brilliant quality is evident from the sturdy construction and precise engineering of the system. Breathtaking service from the support team, who were responsive and helpful throughout the process. Both delivery and setup were smooth, making the entire experience stress-free. Being able to rely on such efficiency is a game-changer for our operations. Beyond compare, this supplier has set a high standard that others should aspire to. Bravo for a job well done!