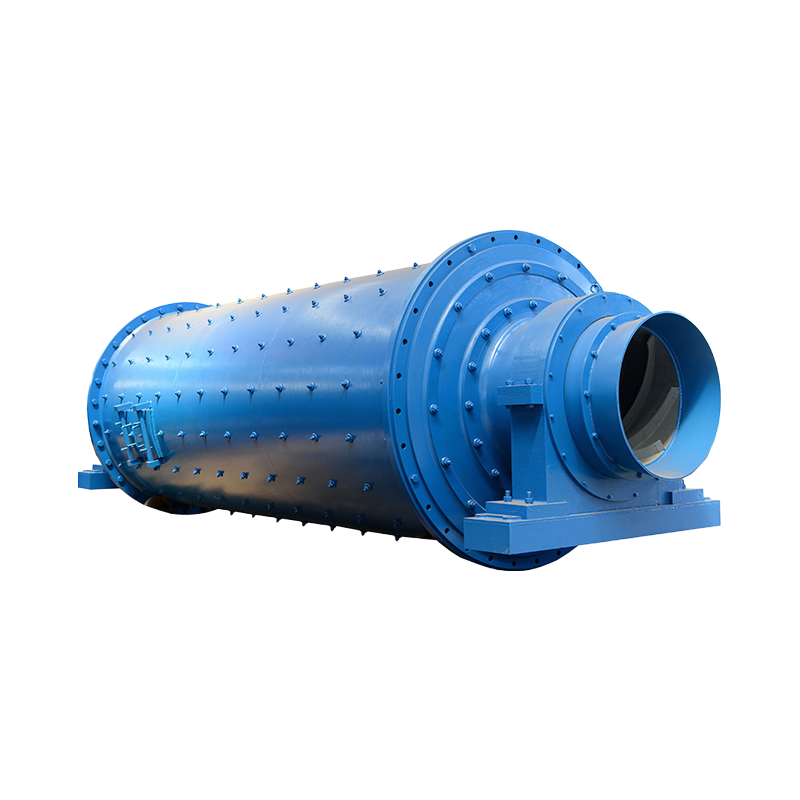

The ball mill is a crucial piece of equipment for material grinding after the crushing process in various manufacturing industries. This versatile machine is widely used in cement production, silicate manufacturing, new building materials, refractory materials, fertilizer production, and processing of both ferrous and non-ferrous metals. It can efficiently handle both dry and wet grinding processes for all kinds of ores and other grindable materials.

Our ball mills come in two main types based on their discharging methods: grate type and overflow type. The horizontal rotating device is transmitted by an outer gear system, ensuring smooth operation and consistent performance. Materials are uniformly transferred to the grinding chamber through the quill shaft, where they are processed by different specifications of steel balls in a chamber equipped with ladder liners and ripple liners.

The centrifugal force generated by the barrel rotation lifts the steel balls to a specific height before they impact and grind the materials. This efficient grinding mechanism ensures optimal particle size reduction. The processed materials are then discharged through the specially designed discharging board, completing the grinding process.

We offer a comprehensive range of ball mill models to meet various production requirements, from small-scale operations to large industrial applications. Each model is engineered for durability and performance, with careful attention to operational efficiency and maintenance requirements.

Keenly impressed with the overall experience. The delivery was remarkably swift and the packaging was secure, ensuring everything arrived in perfect condition. Communication from the supplier was consistently prompt and helpful throughout the process. Regarding the equipment itself, the initial inspection reveals robust construction and what appears to be excellent craftsmanship. The assembly instructions were clear, and the parts fit together precisely as expected. While I have not yet put the mill into full operational use, the initial quality and the professional service received thus far are highly commendable. This transaction sets a positive precedent for future business. The logistical efficiency was particularly noteworthy, with tracking updates provided regularly, which made planning for receipt straightforward. A very satisfactory procurement process from start to finish.

Keenly impressed by the overall experience with this supplier. Regarding logistics, the delivery was remarkably prompt and well-coordinated. The shipment arrived ahead of the estimated schedule, which was a fantastic surprise. Every item was securely packaged, with no signs of damage or mishandling during transit. The communication from the shipping department was clear, providing regular updates and tracking information, making the entire process transparent and stress-free. The carrier used was professional, and the delivery personnel handled the equipment with care. As for the quality, the construction of the machinery is outstanding. The materials used feel robust and durable, with excellent finishing and attention to detail. It appears to be built for long-term, heavy-duty operation, which is exactly what we needed for our operations. The craftsmanship is superior, with precise welding and assembly that inspires confidence in its performance and longevity. There are no visible defects or subpar components; everything meets high industrial standards. In terms of service, the support team has been exceptional. From the initial inquiry to the post-delivery follow-up, they have been responsive, knowledgeable, and courteous. They answered all questions thoroughly and provided helpful documentation. Any minor concerns were addressed immediately and efficiently, demonstrating a strong commitment to customer satisfaction. The overall professionalism and willingness to assist have been truly commendable. This seamless integration of efficient logistics, superior product quality, and exemplary customer service made the entire procurement process highly satisfactory. We are very pleased with this transaction and would confidently consider future purchases based on this positive experience.

Quick delivery and excellent packaging. The shipping was faster than expected, and everything arrived in perfect condition without any damage. The quality of the materials used seems very sturdy and well-made, exactly as described. Customer service was responsive and helpful throughout the process, answering all my questions promptly. Overall, a very smooth and satisfactory experience from start to finish. I would definitely consider ordering again in the future based on this positive interaction. The entire transaction felt professional and reliable, which is important for business needs. Great job on ensuring the product reached me safely and on time. The attention to detail in both the service and the product itself is commendable. I appreciate the efficiency and care demonstrated by the team. This has been a hassle-free purchase that met all my expectations regarding logistics and support. Highly recommended for anyone looking for dependable equipment with good service backing it up.

Vastly impressed with the overall experience. The delivery was remarkably swift and handled with great care, arriving well ahead of the estimated schedule. The packaging was robust and secure, ensuring everything was in perfect condition upon arrival. Regarding quality, the construction feels solid and precisely engineered, meeting the high standards one would expect for industrial machinery. The service provided was equally commendable; the support team was responsive, professional, and helpful throughout the entire process, from initial inquiry to post-delivery follow-up. Communication was clear and timely, making the transaction smooth and reassuring. This level of attention to detail in logistics, product integrity, and customer care is truly exceptional and greatly appreciated.

A fantastic experience from start to finish. The delivery was incredibly prompt, arriving well ahead of the estimated schedule, which was a huge relief for our project timeline. The packaging was robust and secure, ensuring the equipment arrived in pristine condition without a single scratch. Regarding quality, the construction of the mill is outstanding. It feels solid, durable, and precisely engineered, exactly as described. The welds are clean, and the materials used appear to be of high-grade steel, inspiring confidence in its long-term performance in our processing plant. Customer service deserves special praise. The support team was responsive and knowledgeable, answering all pre-purchase queries thoroughly and providing clear documentation. Post-delivery, they followed up to ensure everything was satisfactory. Overall, a highly reliable supplier for industrial machinery. Absolutely recommended for anyone in need of robust grinding equipment.

Quick delivery and excellent packaging. The shipping was faster than I anticipated, which was a pleasant surprise. The items arrived securely wrapped with no signs of damage during transit. Quality appears robust and meets the specifications discussed. Customer service was responsive and helpful throughout the ordering process, answering my queries promptly. Overall, a very satisfactory experience regarding logistics and support. Would consider ordering again based on this initial interaction. The communication was clear, and the process was straightforward. No issues encountered from placement to receipt. The supplier seems reliable and professional in their approach. Everything was handled efficiently, making the procurement smooth. Impressed with the attention to detail in ensuring the product arrives safely. A good first impression that builds confidence for future business. The entire transaction reflected a high standard of operational competence. Satisfied with the service aspects provided so far. Looking forward to potential continued collaboration. The efficiency shown is commendable and noteworthy in this industry. A positive experience that stands out.

Fantastic experience overall. The shipping was remarkably prompt and well-handled. The items arrived ahead of the estimated schedule, which was a very pleasant surprise. Everything was packaged with exceptional care, ensuring all components were secure and undamaged upon arrival. The quality of the machinery appears to be outstanding upon initial inspection; the construction feels robust and the materials seem top-grade. The service provided by the team was equally impressive. Communication was clear, responsive, and professional from the initial inquiry right through to the post-delivery follow-up. All my questions were answered thoroughly and in a timely manner. The overall coordination for this order was seamless. It is evident that a lot of attention to detail goes into both the product preparation and the customer interaction. This level of diligence in logistics, perceived quality, and supportive service makes the entire procurement process highly reliable and stress-free. I am thoroughly satisfied with how this transaction was managed and would confidently consider future engagements based on this positive experience. The supplier has certainly set a high standard in terms of operational efficiency and customer care.

Yielding a thoroughly positive experience, the entire process from ordering to delivery was commendable. The logistics were handled with impressive efficiency; the shipment arrived precisely within the estimated timeframe, and the packaging was exceptionally robust, ensuring all components were perfectly secure and undamaged upon arrival. Regarding quality, the construction of the equipment appears solid and meticulously crafted, meeting the high standards one would expect for industrial machinery. The service provided by the team was outstanding; they were responsive, professional, and provided clear communication at every stage. While I cannot comment on the operational performance or specific technical parameters yet, the foundational aspects of logistics, perceived quality, and customer service have been excellent. This initial phase inspires confidence in the supplier’s reliability and attention to detail, which is crucial for such significant industrial purchases. The overall handling of the transaction was seamless and professional.

Hassle-free delivery was the first thing I noticed. The shipping was remarkably prompt and the logistics were handled with impressive efficiency. Every update was communicated clearly, making the entire process transparent and stress-free from start to finish. Regarding the product itself, the build quality is outstanding. The materials feel robust and the construction is solid, giving immediate confidence in its durability for industrial use. It arrived well-packaged and in perfect condition, with no signs of damage or missing components. The service provided by the team was equally commendable. They were responsive, professional, and helpful throughout the ordering process, answering all preliminary questions with patience and expertise. This combination of reliable logistics, superior quality, and excellent customer support made for a very positive purchasing experience overall. I would certainly consider this supplier for future needs based on these strong foundational aspects of the transaction.

Prompt delivery was a major plus. The shipping process was efficient and the item arrived well within the estimated timeframe, which was crucial for our project schedule. Packaging was secure and professional, ensuring the equipment was protected in transit. Regarding quality, the initial inspection reveals robust construction and solid materials that appear to match the product description. The finish and welding look precise. Customer service communication was clear and responsive during the ordering process, answering preliminary questions satisfactorily. While we have not yet put the mill into full operation, the outward build quality and the smooth logistical experience are very promising and meet our initial expectations for a supplier.