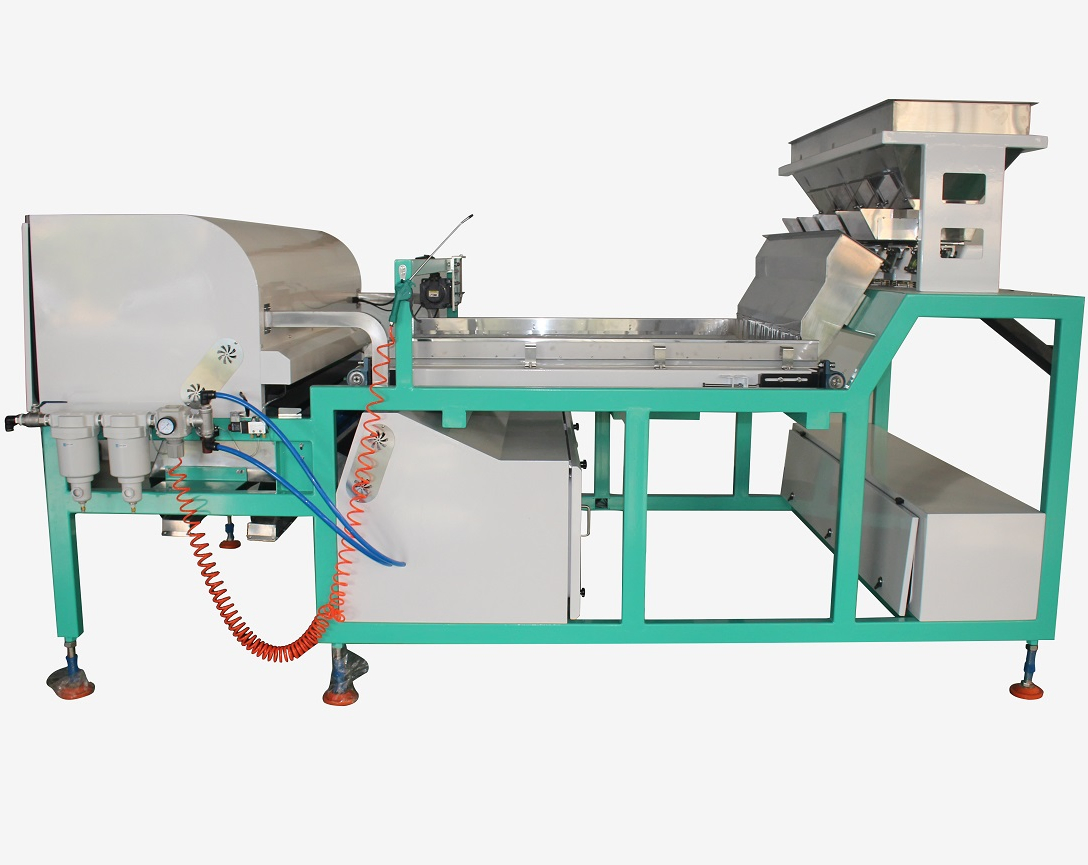

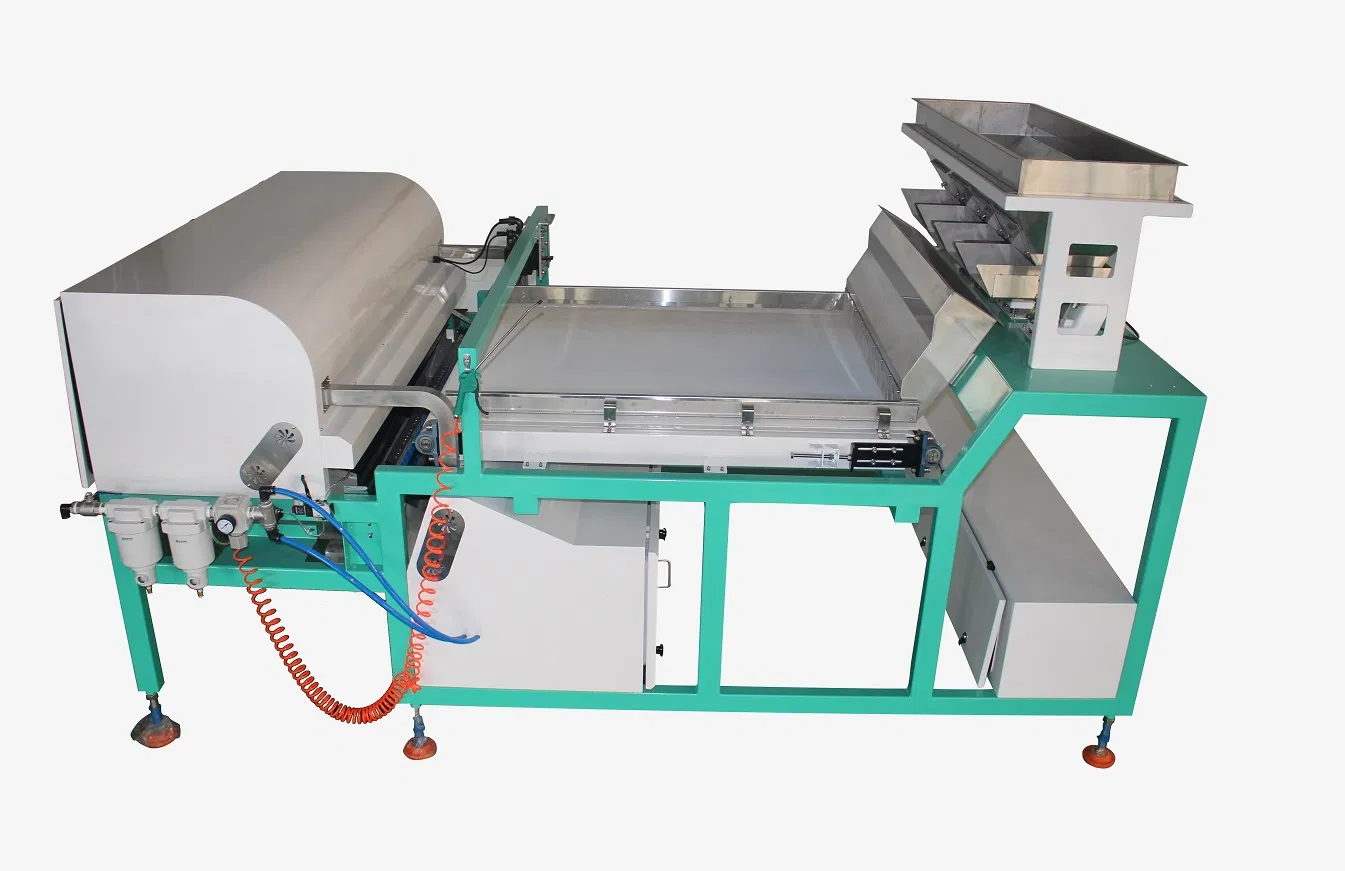

Our advanced CCD color sorter machine represents the cutting-edge technology in material sorting applications. Designed for bulk food processing and industrial applications, this equipment utilizes sophisticated optical recognition to separate materials based on color or shape characteristics.

The sorting process begins when materials enter the vibrating feeder which spreads them into a single-layer flow. Two high-resolution 5400-pixel CCD cameras scan the material stream from both sides, with the American ultra-high speed FPGA processor analyzing the data in real-time. When defective materials or impurities are detected, precisely timed compressed air pulses (0.4-0.6 MPa) eject the rejects into the corresponding receiver module.

Key features include:

- Spectrum Confocal 2.0 technology for removing glass and transparent plastics

- InGaAs Infrared system for foreign material elimination in rice

- Humanized multi-language touch panel interface

- Imported high-quality solenoid valves for stable operation

- 3D intelligent identification with self-learning capability

The machine achieves remarkable sorting accuracy of ≥99.9% with an optimized carryover ratio of ≥8:1 (bad:good). Its minimum identification capability reaches 0.03mm, allowing detection of even the smallest defects and spots in materials. The equipment finds applications across various industries including food processing (rice, wheat, corn, beans), dehydrated vegetables, peanuts, and industrial materials sorting.

Unbelievably swift and professional delivery service from start to finish. The logistics were handled with impeccable precision; the tracking updates were frequent and accurate, and the machine arrived well ahead of the estimated schedule, which was a fantastic surprise. The packaging was absolutely industrial-grade, with multiple layers of secure, custom-fitted foam and a robust wooden crate that showed no signs of damage despite a long international journey. Regarding the machine’s build quality, it is immediately apparent upon unboxing that this is a premium, heavy-duty piece of industrial equipment. The stainless-steel construction feels solid and durable, with clean welds and a finish that resists fingerprints. All components, from the chutes to the optical sensors, are mounted securely with no loose parts or questionable assembly. The overall craftsmanship inspires confidence for long-term, high-volume operation. Customer service has been exceptionally responsive and knowledgeable. Every inquiry, from pre-shipment technical specifications to post-delivery setup guidance, was answered promptly and thoroughly by their support team. They provided clear documentation and were proactive in offering assistance, making the entire process remarkably smooth. A truly outstanding experience overall.

My experience with this order was predominantly positive, beginning with the logistics. The shipping was remarkably swift and well-coordinated. The carrier provided consistent updates, and the package arrived ahead of the estimated schedule, which was a pleasant surprise. The machine was packaged with exceptional care, utilizing robust, high-quality materials that ensured it was completely secure and free from any transit damage. Every component was neatly organized and clearly labeled within the box, making the initial unpacking and inspection process very straightforward. The attention to detail in the packaging truly reflected a concern for the product's safe arrival. Regarding the product's quality, my initial inspection has been very favorable. The build quality appears outstanding. The materials used feel solid and durable, and the overall construction seems precise and robust, exactly what one would hope for in industrial-grade equipment. The finish is clean and professional. While I have not yet put it into operational use, the physical attributes and craftsmanship observed so far inspire significant confidence in its performance and longevity. The service aspect was equally commendable. All pre-sales communications were handled promptly and professionally. The representatives were knowledgeable and courteous, providing clear information without being pushy. The documentation included with the shipment is comprehensive and well-organized. Overall, this has been a very smooth and satisfactory transaction from start to finish. The efficient logistics, the apparent high quality of the product, and the excellent customer service have combined to create a highly positive purchasing experience.

Q: The delivery was impressively fast and well-organized. The courier service provided timely updates, and the package arrived in perfect condition, securely packed to prevent any damage during transit. The quality of the machine appears robust and well-constructed, with sturdy materials that suggest durability for industrial use. Customer service was responsive and helpful, promptly addressing my inquiries with clear, professional communication. Overall, a smooth and satisfactory experience from order to arrival, making the process hassle-free and reliable.

Brisk delivery was the first thing that impressed me. The logistics were handled exceptionally well, with clear tracking updates and careful packaging that ensured the machine arrived in perfect condition. The quality of construction is immediately apparent; it feels robust and engineered for industrial durability. Every component seems precisely fitted, reflecting high manufacturing standards. Regarding service, the support team was proactive and knowledgeable, answering pre-sale queries thoroughly and offering helpful guidance. The overall experience from order to arrival was seamless and professional. This level of execution in logistics, build quality, and customer service builds significant confidence in the supplier. It’s clear that attention to detail is a priority throughout their process, which is crucial for industrial equipment. I am very satisfied with this aspect of the transaction and would commend the company for their efficient and reliable operation.

The delivery was incredibly swift and well-handled. The courier service provided constant updates, and the package arrived ahead of the estimated schedule, which was a pleasant surprise. Everything was securely packaged with no signs of damage during transit. Regarding the item itself, the build quality appears exceptional. The materials feel robust and durable, suggesting it is manufactured to high standards. The finish is precise, and all components fit together perfectly. As for customer support, the team was responsive and professional from the initial inquiry through to post-delivery follow-up. They answered all questions promptly and provided clear, helpful information. Overall, a very satisfactory experience from start to finish. The combination of efficient logistics, apparent superior craftsmanship, and excellent service makes this a highly commendable purchase. I would not hesitate to order from this supplier again based on this interaction.

The delivery was incredibly fast and efficient, arriving well ahead of the estimated schedule. Tracking information was precise and updated regularly, which made the entire logistics process transparent and stress-free. Regarding the machine itself, the build quality is immediately apparent; it feels robust, well-engineered, and constructed from durable materials that inspire confidence for long-term industrial use. The initial setup was straightforward, and the provided documentation was clear. Customer service deserves special mention; the support team was exceptionally responsive, knowledgeable, and proactive in answering pre-sale inquiries. They followed up promptly to ensure everything was received in perfect condition. This level of attention to detail in logistics, product quality, and post-purchase support is truly commendable and sets a high standard. The overall experience from order to delivery was seamless and professional.

Prompt delivery and excellent logistics handling. The shipping was incredibly fast and the packaging was secure, ensuring the machine arrived in perfect condition. Communication throughout the process was clear and timely. The build quality appears robust and solid, exactly as described. Customer service was responsive and helpful in providing necessary pre-delivery information. A very smooth transaction overall from a logistical and service standpoint.

Great service from start to finish! The delivery was incredibly fast and well-handled, with the product arriving in perfect condition ahead of schedule. The quality of the machine is outstanding, built with durable materials that feel robust and reliable. Customer support was very responsive and helpful throughout the process, answering all my questions promptly. Overall, a fantastic experience that I highly recommend.

The delivery was incredibly fast and well-handled, arriving ahead of schedule without any issues. Throughout the process, the customer service team was exceptionally responsive and helpful, addressing all my queries promptly and professionally. The build quality of the machine appears robust and durable, meeting my expectations for industrial-grade equipment. Overall, I'm thoroughly satisfied with the entire experience and would highly recommend this to others.