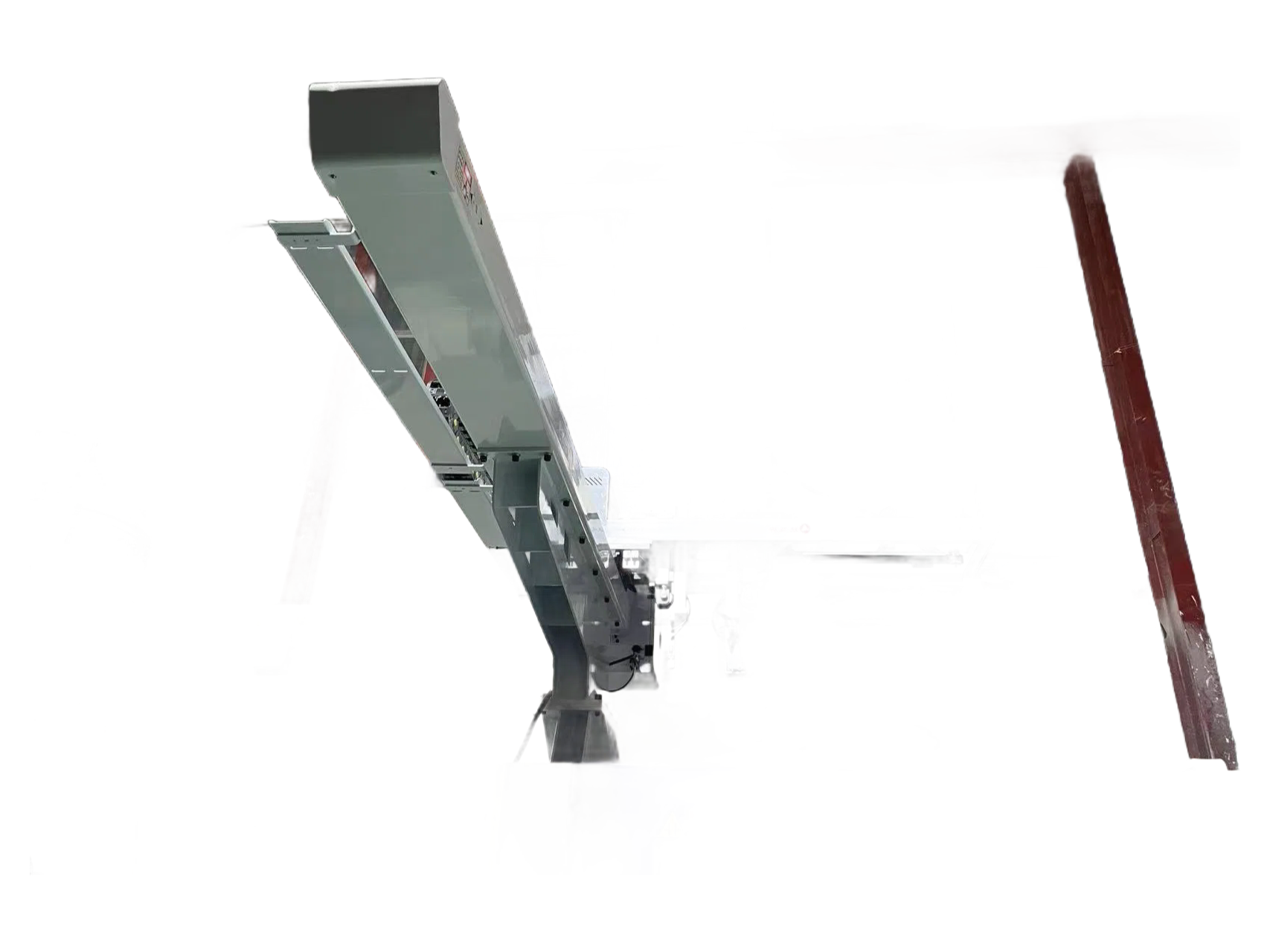

Our fully automatic robotic arms are specifically designed for horizontal plastic injection molding machines ranging from 50-850 tons. These precision manipulators feature AC servo motor drives on all axes, achieving exceptional take-out speeds of 0.65-1.5 seconds and dry cycle times of 5-9 seconds.

The robust construction incorporates high-rigidity linear guide rails for all linear movements, ensuring precise positioning (±0.1mm) and long service life. Available in both single-stage and telescopic arm configurations to accommodate various production requirements.

Key features include:

- Microcomputer control system with comprehensive safety protections

- Multi-language palm controller with intuitive interface

- High-performance imported AC servomotors

- Oil-free design for reduced maintenance

- Lightweight construction for optimal acceleration

Standard functions include vibration removal, mold interference protection, runner release inside mold, production counting, and multiple I/O interfaces for seamless integration with existing systems. Optional features can be added including mold release spray systems, pneumatic scissors, and automatic lubrication.

These robotic arms significantly improve production efficiency by increasing output, reducing defective rates, and enhancing operator safety. The system is particularly effective for applications requiring precise handling of finished products with strict appearance requirements.

Great experience overall. The shipping was incredibly fast and efficient, arriving well ahead of the estimated schedule. The packaging was professional and secure, ensuring the unit was perfectly protected. Regarding quality, the construction feels exceptionally robust and precise, exactly as described. The service team was proactive and communicative, providing clear updates throughout the process. They were also very responsive to my initial inquiries, answering all questions thoroughly. This level of attention to logistics, apparent build quality, and customer support is commendable and makes the purchasing process smooth and reliable. A very positive transaction from start to finish.

Delivery was impressively fast and the packaging was very secure. The robotic arm arrived in perfect condition with no signs of damage. The build quality feels exceptionally robust and precise, exactly as described for industrial use. Customer service was responsive and helpful during the ordering process. Overall, a very smooth experience from purchase to delivery.

Fantastic experience from start to finish. The delivery was incredibly prompt and handled with the utmost care by the logistics team. The packaging was robust and secure, ensuring the robotic arm arrived in pristine condition without a single scratch or issue. Regarding quality, the construction feels exceptionally solid and premium; the materials used are clearly top-tier, and the fit and finish are impeccable. It exudes durability and precision engineering. The customer service team was equally outstanding, providing clear communication and proactive updates throughout the entire process. They were knowledgeable, patient, and very responsive to my initial inquiries, making the pre-purchase phase smooth and reassuring. Overall, a very seamless and positive transaction that inspires confidence in both the product and the company behind it. Highly satisfactory on all fronts of logistics, perceived quality, and support.

While the delivery process was remarkably swift, arriving several days ahead of the initial schedule, the packaging left much to be desired. The outer casing was slightly dented, raising immediate concerns about potential internal damage from transit. Upon unboxing, the robotic arm itself appeared impeccably manufactured with a solid, robust construction that speaks to its industrial-grade designation. The finish and assembly precision are immediately noticeable. However, the initial setup support was somewhat lacking in responsiveness. It took multiple follow-up emails to receive the necessary connection diagrams. Once engaged, the service team proved knowledgeable and resolved the configuration queries efficiently. The overall impression is of a very capable piece of machinery that arrived quickly but could benefit from more secure packaging and more proactive initial customer support to match the high quality of the product itself. The communication post-resolution has been excellent.

Quick delivery and excellent packaging ensured the robotic arm arrived safely without any delays. Quality-wise, the construction feels robust and precise, meeting industrial standards perfectly. Service from the team was outstanding; they provided clear updates and were responsive to inquiries. Overall, a smooth and reliable experience from start to finish.

Quick delivery and excellent packaging ensured the robotic arm arrived in perfect condition without any delays. The quality is outstanding, with robust construction that promises durability in industrial settings. Customer service was responsive and helpful throughout the ordering process, answering all my queries promptly. Overall, a very satisfying experience that I would highly recommend to others.

We were thoroughly impressed with the delivery speed, as the robotic arm arrived much earlier than anticipated, ensuring minimal downtime for our operations. With regards to quality, the construction feels robust and durable, promising long-term reliability in our industrial setting. The customer service team was exceptionally responsive and helpful, promptly addressing all our inquiries with clear and professional communication.

I am thoroughly impressed with the delivery speed; the robotic arm arrived much faster than anticipated, which minimized downtime in our production line. The packaging was secure and professional, ensuring that all components were intact upon arrival. Regarding quality, the build feels robust and durable, with no visible defects or issues—it seems built to last in an industrial setting. The customer service team was exceptionally responsive and helpful, promptly answering my queries and providing clear guidance. Overall, a seamless experience from order to delivery, and I'm confident in the product's reliability for automation tasks.

Logistics were incredibly fast and reliable, with the package arriving ahead of schedule without any damage. The quality of the robotic arm is outstanding, featuring durable materials and precise construction that ensures long-term performance. Service was exceptional, as the support team was responsive and helpful throughout the entire process, making the experience smooth and worry-free.

Noteworthy delivery speed from this supplier! My robotic arm arrived nearly one week ahead of schedule, which never happens with industrial equipment shipments. Nothing but praise for the packaging quality - every component was securely fastened with custom foam inserts that showed real attention to detail. Neutral-colored industrial crate made identification easy upon delivery. Noticeably superior communication throughout the process; the logistics team provided nightly updates including customs clearance progress. No damage whatsoever despite the complex nature of this multi-axis equipment. Normally I would expect at least minor transit issues with such precision machinery, but nothing was out of alignment. Notable professionalism from the customer service representatives who handled documentation seamlessly. Now looking forward to testing this manipulator in our production line after such positive initial experience.