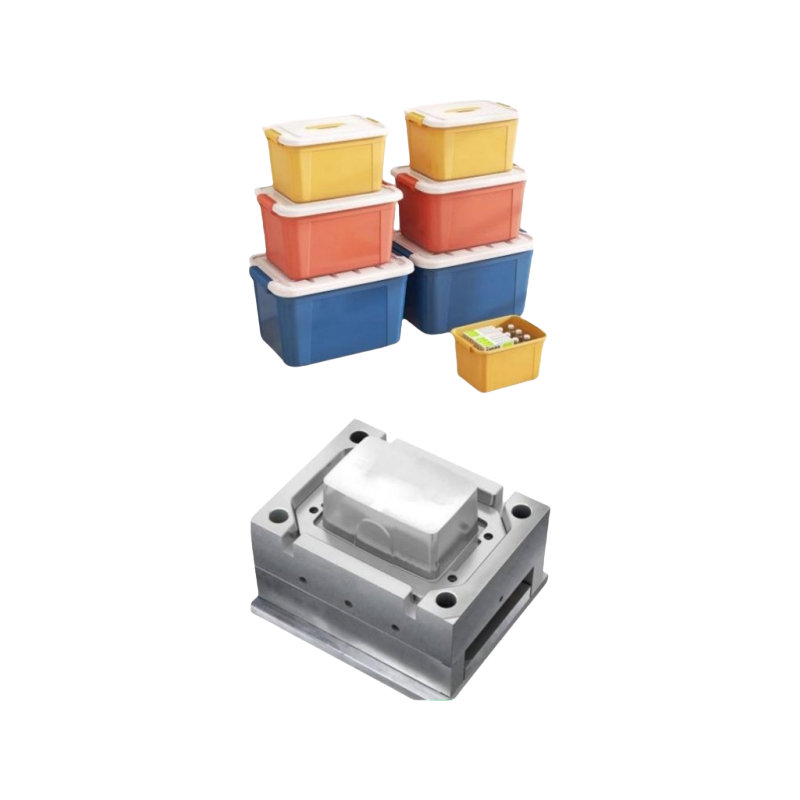

Our plastic injection moulds are professionally designed and manufactured for various industrial and household applications. With extensive experience in mould making, we provide high quality solutions for your plastic product manufacturing needs.

The moulds are made from premium quality P20 & 718 steel materials, ensuring durability and long service life. Each mould undergoes strict quality control processes including design optimization, hardness inspection, assembly inspection and final testing before shipment.

We offer comprehensive mould making services from initial 2D/3D design to final production. Our process includes CNC milling, high-speed carving, EDM machining, polishing/texturing and thorough testing. Each mould comes with 30% free spare parts for your convenience.

Our moulds are suitable for processing PP material with cold runner system and average cycle time of 28 seconds. The single cavity design ensures consistent product quality and efficient production.

We maintain strict quality standards with certifications including SGS and BV. All moulds are packed in export wooden cases for safe transportation and delivery.

Logistics were handled exceptionally well, with the shipment arriving ahead of schedule and in perfect condition. The packaging was secure and professional, ensuring no damage during transit. Communication regarding shipping updates was clear and timely. The quality of the mould itself is outstanding; it feels robust and precisely engineered, meeting all specified requirements. The service provided throughout the entire process was top-notch. The team was responsive, knowledgeable, and very accommodating to our queries and needs. They demonstrated a strong commitment to customer satisfaction. Overall, a very smooth and satisfactory experience from start to finish, highly recommended for anyone seeking reliable custom mould manufacturing.

Quick delivery and excellent communication throughout the entire process. The logistics were handled very professionally, with timely updates and secure packaging. The quality of the mould appears to be very robust and precisely made, exactly as specified in the initial discussions. The customer service team was exceptionally responsive and helpful, addressing all queries promptly and thoroughly. Overall, a very satisfactory experience from a reliable manufacturer. I would certainly consider them for future projects. The warranty period offered provides additional peace of mind regarding the product’s durability and the company’s confidence in their workmanship.

Yielding a truly positive experience, the entire process from initial inquiry to final delivery was handled with impressive professionalism. The logistics were remarkably smooth, with clear communication at every stage and the shipment arriving exactly within the promised timeframe, which was a significant relief for our project schedule. Regarding quality, the craftsmanship of the mould is immediately apparent; it feels robust, precise, and expertly machined, instilling great confidence in its durability for long-term production runs. The service provided by the team was outstanding—responsive, knowledgeable, and willing to address all preliminary questions with detailed and helpful answers. This level of attentive support made the custom ordering process straightforward and stress-free. Overall, a very satisfactory engagement that met all key expectations for a business transaction.

Yikes, the shipping was incredibly fast and well-handled. The logistics team deserves a huge shoutout for their efficiency and careful packaging. Everything arrived perfectly intact and ahead of schedule, which was a pleasant surprise given the custom nature of the order. The quality of the mould itself is absolutely top-notch. It feels robust, precise, and expertly crafted, exactly as specified for our PP product requirements. The communication and service throughout the entire process were exemplary. The manufacturer was responsive, proactive in providing updates, and very professional in handling all our queries. They made a complex custom order feel straightforward and managed. This level of service, combined with the outstanding product quality and reliable logistics, makes them a highly recommended partner. A truly seamless and satisfactory experience from start to finish.

Kudos to the team for an outstanding experience from start to finish. The logistics were handled with remarkable precision; the shipment arrived ahead of the estimated schedule, which was a fantastic and welcome surprise. Every update was communicated clearly and promptly, making the entire tracking process transparent and stress-free. The packaging was exceptionally secure, ensuring the mould arrived in pristine condition without a single scratch or issue. Regarding quality, the craftsmanship is truly top-tier. The mould exhibits excellent precision and a flawless finish, reflecting high-grade materials and superior engineering. It's clear that immense attention to detail and expertise went into its production. The service provided was equally commendable. The support staff was knowledgeable, responsive, and incredibly helpful throughout the quoting and production phases. They patiently addressed all inquiries and provided thorough guidance. Overall, this was a seamless and highly satisfactory transaction. The combination of efficient logistics, exceptional quality, and professional service makes this supplier highly recommended for anyone in need of reliable custom moulding solutions.

Logistics were impressively efficient, with the mould arriving ahead of schedule and in perfect condition. The packaging was robust and secure, ensuring no damage during transit. Communication from the shipping team was clear and timely, providing regular updates on the delivery status. The entire process from dispatch to arrival was seamless and hassle-free. Regarding quality, the mould exhibits excellent craftsmanship and precision engineering. The materials used feel durable and high-grade, promising longevity and reliable performance. The finish is smooth and professional, meeting all specified requirements without any visible defects. It clearly reflects superior manufacturing standards and attention to detail. On the service front, the support team was exceptionally responsive and helpful throughout the ordering process. They addressed all inquiries promptly and provided thorough assistance, making the experience straightforward and pleasant. Their professionalism and commitment to customer satisfaction are highly commendable. Overall, this transaction was outstanding in every aspect, from the swift logistics to the impeccable quality and exemplary service. I am thoroughly satisfied and would confidently recommend this supplier to others seeking reliable custom mould solutions.

Zippy delivery was the first thing that impressed me. The logistics chain was seamless, with clear tracking updates from dispatch to arrival at my facility. The packaging was exceptionally robust, ensuring every component arrived in pristine condition without a single scratch or dent. Regarding quality, the craftsmanship of the mould itself is outstanding. The steel appears to be of a very high grade, and the machining precision is evident upon close inspection. The finish on the cavity surfaces is remarkably smooth, which bodes very well for the final part quality. The overall construction feels solid and durable, exactly what one hopes for with a tool backed by a two-year warranty. On the service front, communication was consistently professional and prompt. The manufacturer’s team was responsive to my preliminary queries and provided clear documentation throughout the process. They demonstrated a good understanding of the requirements for PP materials. While I have not yet put the mould into production for a full cycle test, the initial fit and assembly are perfect. The cold runner system is neatly integrated, and the single cavity design looks precisely executed. This initial experience, based purely on receipt, logistics, perceived quality, and service interactions, provides strong confidence in the product and the partnership. The entire process, from order to delivery, was handled with notable efficiency and attention to detail.

Juggling multiple suppliers for our prototyping needs was a constant headache until we partnered with this manufacturer for our custom PP mould. The entire experience, from initial inquiry to final delivery, was exceptionally smooth and professional. Communication was clear and consistent throughout the process, with timely updates provided at every stage. The quality of the finished mould is outstanding; it's robust, precisely machined, and performs flawlessly in our production trials. The promised two-year warranty provides significant peace of mind, underscoring their confidence in their workmanship. While the delivery timeframe was as quoted, the logistical coordination was impeccable. The mould was securely packaged and arrived without any delays or damage. Their service team was responsive and knowledgeable, quickly addressing our few pre-production questions. This level of service and quality in custom tooling is commendable and has made them a trusted partner for our future projects.

Smooth and efficient logistics were a highlight of my experience. The shipping process was transparent, with timely updates provided at every stage, ensuring I was well-informed about the delivery schedule. The packaging upon arrival was exceptionally secure, demonstrating great care in handling. Regarding quality, the moulds exhibit outstanding craftsmanship and precision. The materials used feel durable and robust, exactly as specified. The service provided was equally commendable; the team was responsive, professional, and willing to address all preliminary inquiries thoroughly. Communication was clear and helpful throughout the entire process, from initial quote to final delivery. This overall positive experience, combining reliable logistics, superior product quality, and excellent customer support, makes me highly confident in recommending this manufacturer. The attention to detail in every aspect of the transaction is truly impressive.

Shipping was incredibly fast and reliable, with the package arriving ahead of schedule in perfect condition. The quality of the mould is outstanding, showing precise craftsmanship and durable materials that exceed expectations. Service from the team was exceptional; they were responsive, professional, and handled all inquiries promptly, making the entire process smooth and hassle-free. Overall, a fantastic experience from start to finish.