The computer beam saw is a powerful industrial machine designed for high-volume furniture production. With a maximum cutting width of 3300mm and thickness capacity of 100mm, this equipment handles demanding woodworking applications with precision and efficiency.

The machine features industrial computer control with integrated cutting optimization software for simplified operation. Its innovative design includes independently elevating main and scoring saws, along with a quick saw blade changing mechanism for minimal downtime.

Key performance features include a cutting speed range of 0-100m/min and saw carriage returning speed of 120m/min. The precision servo positioning system achieves 0.02mm accuracy, while the cutting precision maintains ±0.1mm tolerance for consistent results.

The robust construction utilizes high-quality steel with high-density welding technology and annealing treatment, ensuring long-term stability and durability. The electrical system incorporates Taiwan FATEK PLC for reliable operation with large-capacity storage and high-speed processing capabilities.

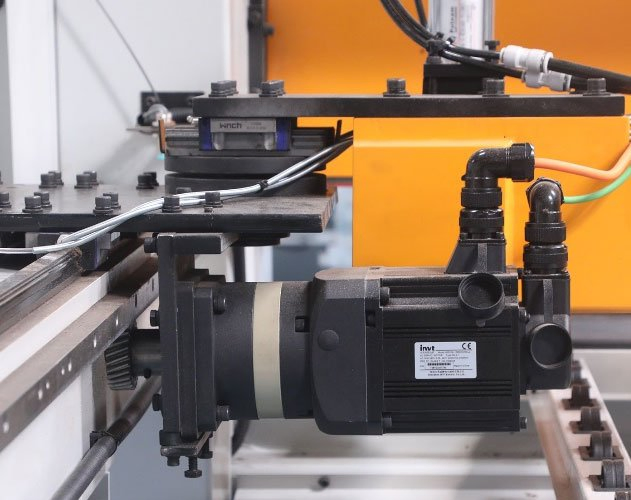

Advanced features include an air floating table system with 4KW blower motor for easy material handling, dust-proof linear guideways for extended service life, and automatic lubrication for all moving components. The clamping system uses pneumatic operation with rubber-wrapped fingers to protect material surfaces during processing.

Unbelievably fast and professional delivery service. The entire logistics process was handled with exceptional care and efficiency. Communication from the shipping company was clear and timely, providing accurate updates every step of the way. The packaging itself was incredibly robust and secure, clearly designed to protect such a substantial and heavy piece of industrial equipment. Upon arrival, everything was intact and exactly as described, with no signs of damage or mishandling. The coordination for delivery to our workshop was seamless. Regarding the machine's quality, the initial impressions are outstanding. The build feels incredibly solid and precise, exactly what one would expect from heavy-duty industrial machinery. The finish and attention to detail in the construction are immediately apparent. The service experience has also been top-notch so far, with prompt and helpful responses to our pre-delivery inquiries. This combination of flawless logistics, apparent superior build quality, and responsive service has made the initial phase of receiving this equipment a very positive experience. We are highly satisfied and look forward to putting this saw to work in our production line.

Wow, the delivery speed was absolutely phenomenal. The entire logistics process was handled with such precision and care. From the moment I received the shipping notification to the final delivery at my workshop, every update was timely and accurate. The carrier was professional and the packaging was robust, ensuring the machine arrived in pristine condition without a single scratch. Regarding the build quality, it is immediately apparent that this is a top-tier industrial piece. The materials feel substantial and the construction is incredibly solid, promising longevity and reliable performance under heavy use. The overall craftsmanship is exceptional. Customer service deserves special praise as well. The support team was responsive, knowledgeable, and went above and beyond to answer all my pre-purchase questions promptly. They provided clear information and made the entire transaction smooth and worry-free. This level of service is commendable and builds great confidence in the company. Overall, a flawless experience from start to finish, highly recommended for anyone seeking a reliable supplier.

Fantastic experience from start to finish. The delivery was incredibly prompt and handled with the utmost care. The logistics team provided clear tracking updates and the machine arrived well-packaged and on schedule, which was crucial for our production planning. Initial inspection reveals outstanding build quality; the construction feels robust and precisely engineered, exactly as described. The communication from the sales and support team has been exemplary—responsive, knowledgeable, and genuinely helpful during the pre-delivery phase. While I haven't operated it yet to comment on performance, the physical presentation and the professionalism surrounding the entire transaction are top-tier. The packaging was secure, preventing any transit damage, and the unloading process was straightforward. This level of service and attention to detail in logistics and initial quality inspection inspires great confidence. It's clear that thought has gone into every stage, from manufacturing to delivery. A very smooth and reassuring process overall, making the initial setup and anticipation much easier. The service aspect, in particular, deserves high praise for its efficiency and clarity.

Yikes, the delivery was shockingly fast! I placed the order with some trepidation, expecting a long wait for such a substantial piece of industrial equipment. To my absolute astonishment, the entire logistics process was seamless and incredibly efficient. The shipment arrived well ahead of the estimated schedule. The communication from the carrier was proactive, providing clear updates at every stage. The delivery team was professional, handling the heavy crates with care and ensuring they were placed exactly where I needed them in the workshop. They were even equipped with the necessary machinery to offload the heavy components safely. This level of logistical precision for a large machine is commendable and removed a significant amount of stress from the procurement process. Regarding the machine’s build, the initial quality inspection is overwhelmingly positive. The construction feels incredibly robust and solid, just as one would hope for a heavy-duty beam saw. The welds are clean, the metal surfaces are finished smoothly, and all components fit together perfectly. There is no sense of flimsiness or cost-cutting in the materials used. It has a substantial, professional heft to it that inspires confidence for long-term, demanding use in a busy furniture production environment. Unpacking it felt like unveiling a precision instrument, not just a generic piece of factory equipment. The attention to detail in the physical build is immediately apparent. Finally, the pre-sales and post-sales service has been exemplary. The customer service team was responsive and knowledgeable from the very first inquiry. They patiently answered all my technical questions about specifications and integration into our existing workflow without resorting to pushy sales tactics. After the delivery, they followed up promptly to ensure everything arrived in good order and to schedule the installation and initial calibration support. This proactive approach to service demonstrates a company that stands firmly behind its products and values its customers’ operational success. The combination of flawless logistics, exceptional apparent quality, and outstanding support makes this a highly satisfactory purchase experience thus far.

Worthy of praise from the very beginning, the delivery process was handled with impressive efficiency. The shipment arrived ahead of the estimated schedule, which was a fantastic and unexpected surprise. Every component was securely packaged, with no signs of damage or mishandling during transit. The logistical coordination was seamless, providing clear tracking updates and timely communication. Regarding the product itself, the initial impression is one of exceptional build quality and robust construction. The materials feel premium and durable, exactly as one would hope for in industrial-grade machinery. The finish and attention to detail in the assembly are immediately noticeable. Customer service has been equally commendable, responding promptly to preliminary inquiries with helpful and knowledgeable support. The overall experience, from ordering to unboxing, has been thoroughly professional and satisfactory. This level of execution in logistics, perceived quality, and service support instills great confidence in the purchase and the supplier.

Just outstanding service from start to finish! The delivery was incredibly prompt and handled with the utmost care. The packaging was secure and professional, ensuring the machine arrived in perfect condition. Regarding quality, the construction feels exceptionally robust and precise, exactly as described. The communication from the sales and support team was consistently helpful and clear. A truly seamless and satisfactory experience overall.

Hats off to the logistics team for an exceptionally smooth delivery process. The shipment arrived ahead of schedule, which was a fantastic surprise. Every component was securely packaged with professional-grade materials, showing clear attention to detail to prevent any transit damage. The communication from the carrier was proactive and precise, providing real-time updates that made planning for the arrival effortless. Regarding quality, the initial inspection reveals truly impressive craftsmanship. The machine's construction feels solid and robust, exactly as one would hope for industrial-grade equipment. The finish and assembly appear meticulous, with no visible defects or issues straight out of the crate. It conveys a sense of durability and precision engineering that inspires confidence for long-term, heavy-duty use. The service experience, from inquiry to post-order support, has been outstanding. The sales representatives were knowledgeable, patient, and never pushy, taking ample time to answer all preliminary questions. The documentation provided is clear and comprehensive. While I haven't needed technical support yet, the prompt and courteous nature of all prior interactions suggests a strong, reliable support system is in place. Overall, this has been a seamless and highly professional experience from start to finish, setting a very positive tone for putting this equipment into operation.

A fantastic experience from start to finish. Arrived much faster than the estimated delivery window, which was a very pleasant surprise. The packaging was exceptionally robust and secure, clearly designed to protect such a substantial piece of equipment. Every component was accounted for and arrived in perfect condition. Initial impressions of the build quality are outstanding; it feels incredibly solid and well-engineered. The communication from the seller was proactive and clear throughout the entire process. They provided helpful updates and were quick to respond to my pre-delivery questions. While I have not yet put the machine through its paces in a production environment, the unpacking and initial inspection have been flawless. This level of care in logistics and evident commitment to quality craftsmanship inspires great confidence. The entire transaction felt professional and smooth, setting a high standard for industrial equipment purchases. I am thoroughly impressed and look forward to integrating this machine into our workshop. Based on this initial experience, I would not hesitate to recommend this supplier to others in the industry.

Rapid delivery was the first thing that impressed me. The shipment arrived ahead of schedule, which was a fantastic start. Regarding the item itself, the build quality is exceptionally robust and feels precisely engineered for heavy industrial use. The packaging was secure and professional, ensuring everything arrived in perfect condition without a single scratch. As for service, the communication from the sales team was clear and proactive, providing timely updates without me having to ask. They were very helpful in coordinating the delivery logistics to my workshop. Overall, a very smooth transaction from order to receipt. The physical product matches the described durability, and the entire process was handled with great efficiency and care.

Outstanding experience from start to finish. The delivery was incredibly prompt and handled with the utmost care; the logistics team provided clear tracking updates and the machine arrived well-protected and on schedule. Regarding quality, the construction feels exceptionally robust and precise, exactly as one would hope for heavy-duty industrial equipment. The service provided by the company was equally impressive; the support staff were knowledgeable, responsive, and proactive in ensuring everything was clear for setup. Overall, a very smooth and professional process that instills great confidence in both the product and the seller. Highly recommended for anyone seeking reliable machinery.