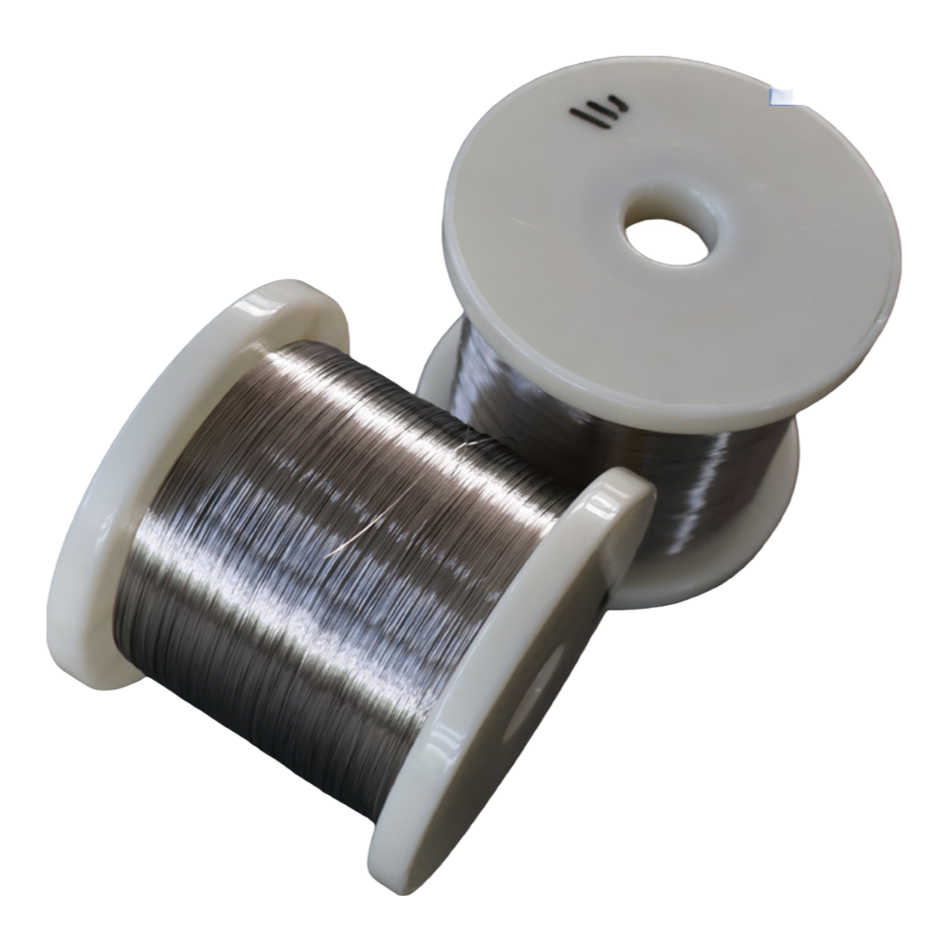

Nickel-chromium (NiCr) alloys are premium materials known for their exceptional corrosion resistance and high temperature stability. These alloys primarily consist of nickel and chromium, often with additional elements like molybdenum, iron or copper to enhance specific properties.

NiCr wires are widely used across multiple industries including chemical processing, aerospace, energy production, and medical applications due to their unique combination of properties:

• Outstanding corrosion resistance against acids, alkalis and salt solutions

• Excellent high temperature stability with minimal deformation

• Superior mechanical strength and toughness

• Low thermal expansion coefficient

• Good electrical conductivity

Our manufacturing process ensures consistent quality through strict control at each stage:

1. Precise raw material selection and blending

2. High-temperature melting in controlled atmosphere furnaces

3. Continuous casting for uniform ingots

4. Comprehensive heat treatment cycles

5. Precision machining and surface finishing

6. Rigorous quality testing and inspection

Common applications include:

• Heating elements for industrial furnaces and appliances

• Aerospace engine components

• Chemical processing equipment

• Medical implants and devices

• Electronic components and resistors

• Automotive exhaust systems

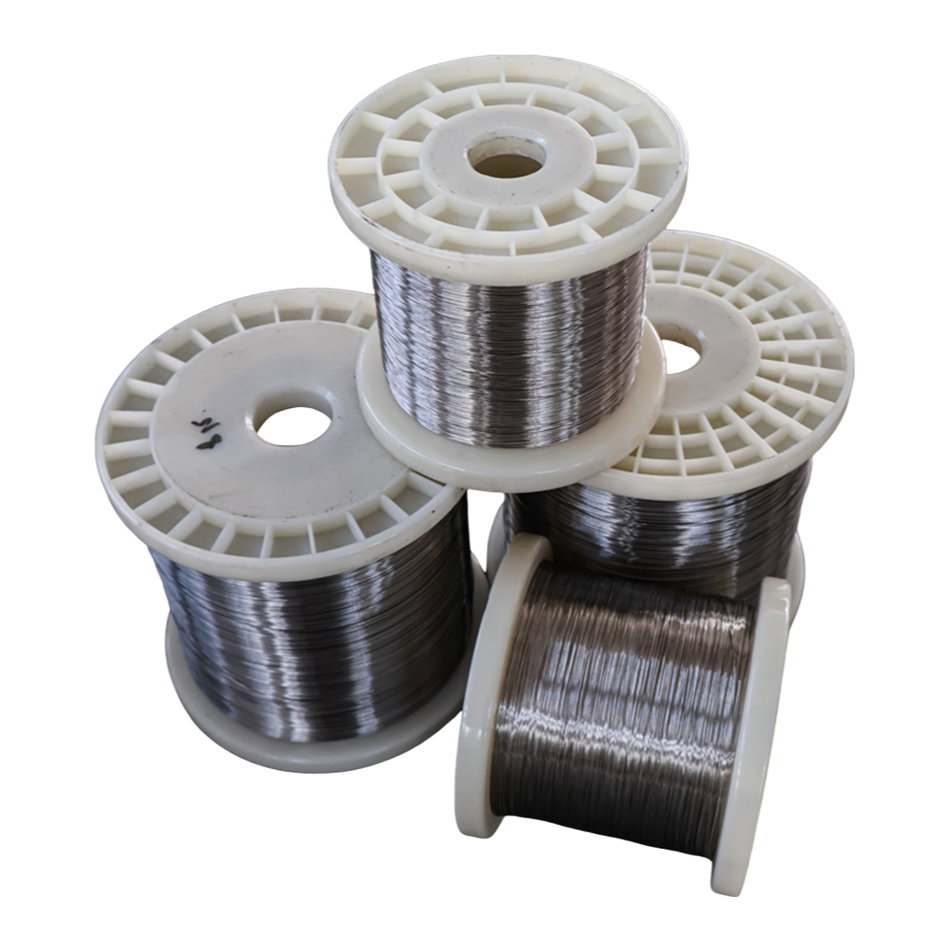

We offer customization options for diameter, composition and surface finish to meet specific application requirements.

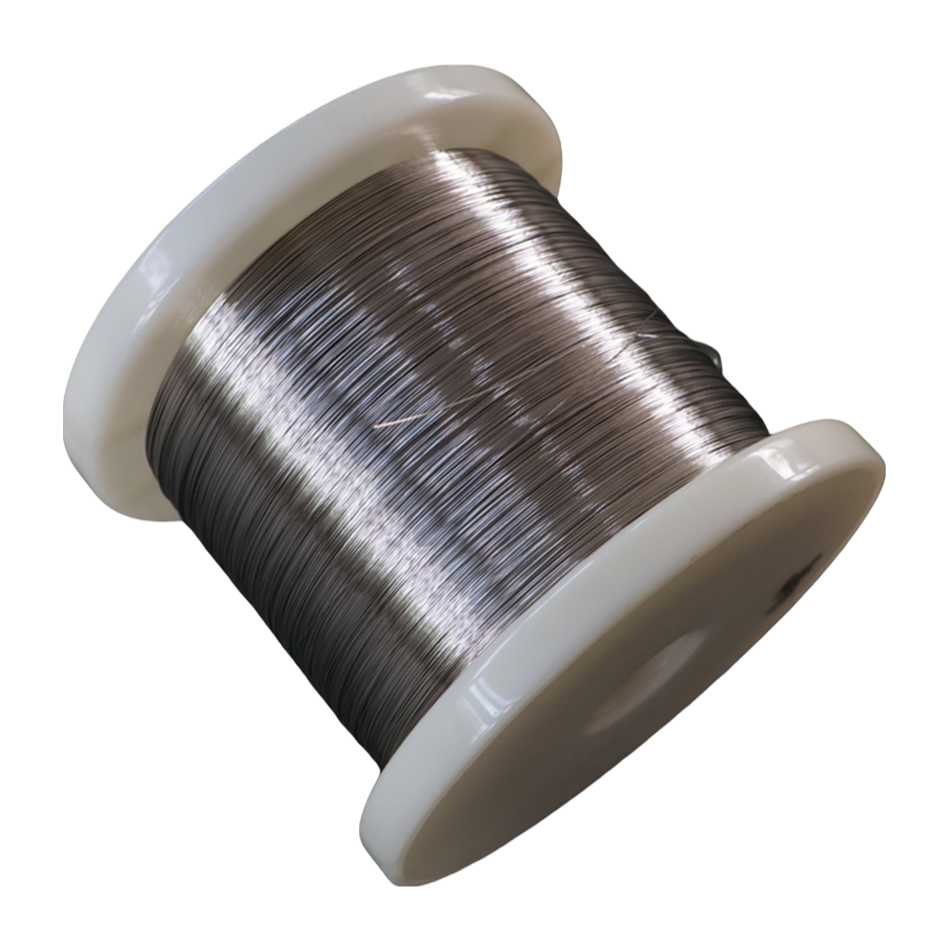

Xcellent experience from start to finish. The delivery was remarkably fast, arriving well ahead of the estimated schedule. The packaging was secure and professional, ensuring the product arrived in perfect condition. Regarding quality, the wire appears to be exactly as described, with a consistent gauge and a finish that suggests careful manufacturing. The material feels robust and suitable for high-temperature applications as advertised. Customer service was responsive and helpful when I had a pre-purchase inquiry, providing clear and timely information. Overall, a very smooth transaction with no issues encountered. I am confident in the product based on initial inspection and the professional handling of the order. The logistics were seamless, the quality seems promising, and the service was courteous and efficient. This has been a positive purchasing experience that inspires confidence for future orders. The combination of reliable shipping, apparent product integrity, and supportive service makes this supplier stand out. I would certainly consider them again for similar industrial needs. The entire process was handled with a level of professionalism that is commendable and somewhat rare. It’s refreshing to have an order arrive so promptly and in such good order without any complications or delays. The attention to detail in both the product presentation and the customer interaction was notable. A very satisfactory purchase all around.

Prompt delivery and excellent packaging ensured the wire arrived in perfect condition. The quality appears top-notch, with no visible defects, and it feels durable for industrial use. Customer service was responsive and helpful when I had a query, making the overall experience smooth and satisfactory.