The SBT Type elastic spider coupling is a high-performance component designed for industrial shaft transmission systems. This coupling element is particularly suitable for water pumps and mechanical cushioning applications, providing excellent vibration absorption and torque transmission capabilities.

Manufactured from premium NBR or CPU/TPU materials, our SBT spider couplings offer exceptional resistance to wear, oil, ozone, and aging. These properties make them ideal for operation in demanding environments, including tropical climates where hydrolysis resistance is crucial.

The polyurethane elastomeric material combines the high strength of plastic with the elasticity of rubber, featuring a wide hardness range from Shore A70 to A98. This unique combination provides superior tensile strength (8-55MPa), tear resistance (35-155KN/m), and outstanding wear resistance that outperforms conventional rubber materials by 3-5 times.

Key advantages of our SBT spider couplings include:

1. Excellent vibration absorption and buffering performance

2. Superior resistance to mineral oils and mechanical oils

3. Good low-temperature performance down to -40°C

4. High radiation resistance

5. Easy machining and installation

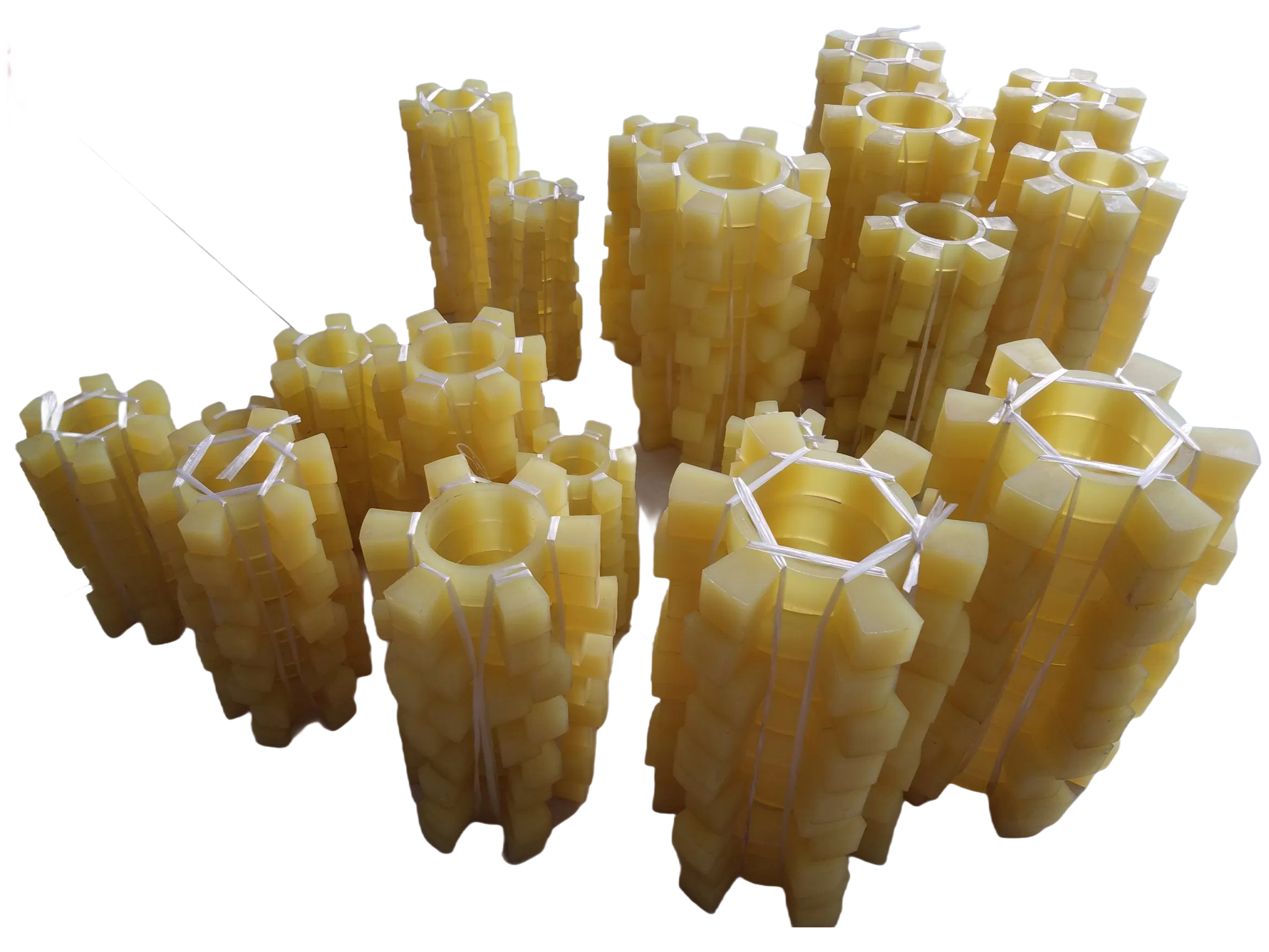

Our product range covers standard sizes from T40 to T210, with custom sizes available upon request. The couplings are available in black or natural color, and can be produced with customer-specific logos for OEM applications.

The SBT spider couplings are compatible with various industrial metal shaft couplings including GR, GS, MT, ML, MH, Hb, HRC series. They provide reliable performance in water and oil environments, with working temperatures ranging from -30°C to +100°C.

With nearly 10 years of manufacturing experience and cooperation with scientific research institutions, we maintain strict quality control to ensure each coupling meets the highest industry standards. Our production capabilities include full sets of injection molds for various coupling types and sizes.