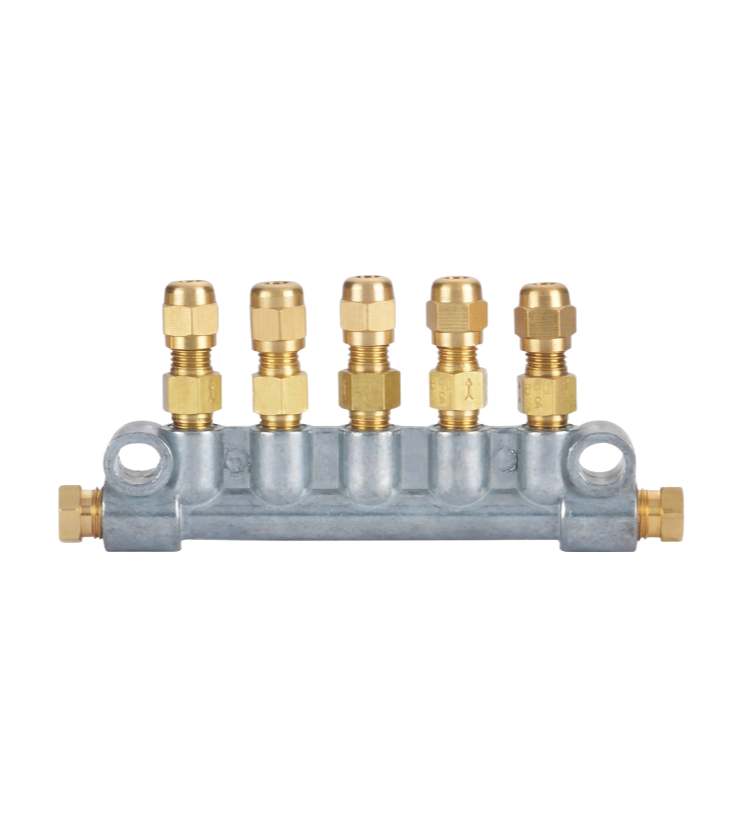

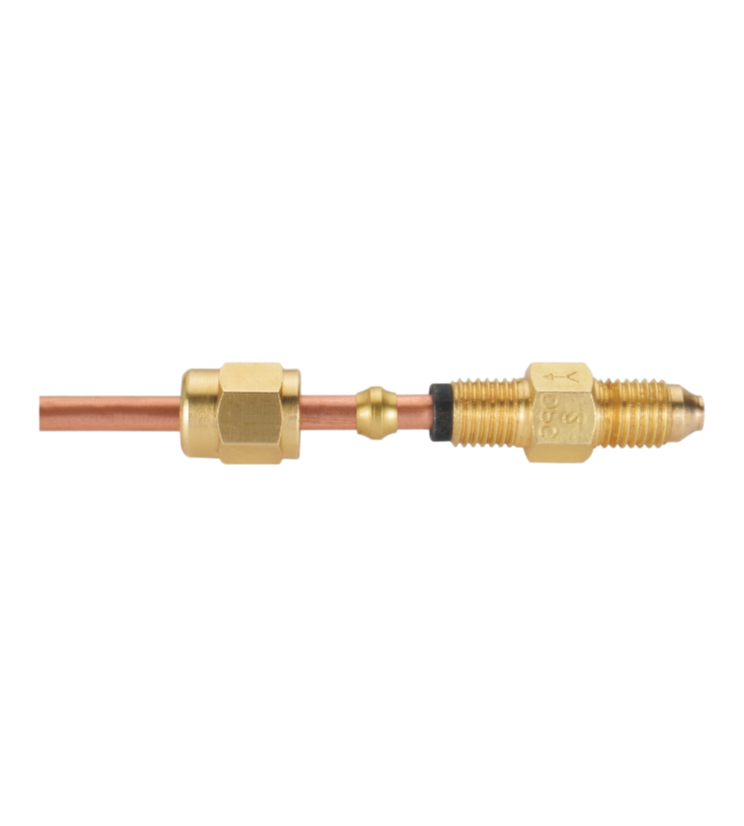

BSB type proportional joint fittings are essential components in auto lubrication systems, designed to ensure precise and consistent oil distribution. These fittings incorporate a built-in flow limit bar and a one-way valve, which work together to control flow based on the throttling principle. The flow remains constant regardless of installation orientation—whether near, distant, high, low, horizontal, or vertical—making them highly versatile for industrial applications.

The proportional joint features a copper sleeve coating on rubber sealing parts (excluding the sealing face) to prevent expansion and aging, significantly extending the service life. A taper spring is used in the one-way valve mechanism to ensure sensitive and smooth oil drain action, effectively preventing reverse oil flow. This design enhances reliability and performance in demanding environments.

Flow ratio may vary with changes in environmental temperature and oil viscosity, but the BSB models maintain consistent performance across different conditions. Available in multiple models with specific flow coefficients, these fittings cater to various lubrication needs. The construction includes brass material for corrosion resistance, a hexagon head for easy installation, and a galvanized surface treatment for added durability.

These proportional joint fittings are ideal for use in centralized lubrication systems, providing efficient and reliable operation. They are manufactured to DIN standards, ensuring compatibility and quality. The design focuses on longevity and minimal maintenance, making them a cost-effective solution for industrial lubrication requirements.

Delivery was incredibly prompt and well-handled. The packaging was secure and professional, ensuring the items arrived in perfect condition without any delays. I was thoroughly impressed by the efficiency of the shipping process. Regarding quality, the brass material feels robust and precisely manufactured, meeting the high standards one would expect. The fittings appear durable and reliable for long-term use. Customer service was exceptional; the team was responsive, knowledgeable, and very helpful in addressing my pre-purchase inquiries. They provided clear information and support throughout. Overall, a very satisfactory experience from start to finish. Definitely recommend this supplier for their outstanding logistics, product quality, and excellent service.

My experience with this order was quite positive overall. Regarding logistics, the shipping was prompt and the package arrived well ahead of the estimated delivery window, which was a pleasant surprise. The items were securely packaged with ample protective material, preventing any damage during transit. The tracking information provided was accurate and updated regularly, allowing me to monitor the shipment’s progress with ease. As for the quality, upon inspection, the brass material feels solid and well-machined, meeting the expected standards. The fittings appear precisely manufactured, with clean threads and a good finish, suggesting durability. The service aspect was also satisfactory; communication was clear, and any preliminary questions I had were answered in a timely manner. The overall process from ordering to delivery was smooth and hassle-free. While I cannot comment on the specific performance or technical parameters in use, the initial impressions based on logistics, perceived quality, and customer service are very good. This transaction met my expectations for a reliable purchase.

Yikes, the shipping was incredibly slow and the tracking information was practically non-existent. It took weeks longer than the estimated delivery window, which caused significant delays in our project timeline. Once the items finally arrived, the packaging was subpar and one of the fittings had minor cosmetic damage from what appeared to be rough handling during transit. However, the quality of the brass material itself seems robust and meets the stated DIN standard specifications. The machining appears precise. Customer service was responsive when contacted about the shipping delay, though their initial responses were generic and unhelpful. They did eventually escalate the issue, but the resolution took too long. The overall experience was frustrating due primarily to the logistical failures, overshadowing what seems to be a decent quality product.

Xcellent experience overall! The shipping was incredibly fast and reliable, with my order arriving well ahead of schedule, which was a pleasant surprise. The quality of the items is outstanding; they feel durable and well-made, giving me confidence in their longevity. Customer service was top-notch too—responsive and helpful with any inquiries I had. Highly recommend for anyone seeking efficient and dependable products.