The automatic water bottling machine is designed for efficient liquid packaging in beverage production lines. This equipment integrates bottle rinsing, filling and capping functions with advanced PLC control system for precise operation.

Constructed with high-quality stainless steel (304/316), the machine features multi-head filling valves and single-room feeding structure. It achieves 99.5% filling accuracy and supports bottle volumes from 200ml to 2 liters. The rotary design ensures smooth operation with minimal maintenance requirements.

This production line is suitable for various beverage types including mineral water, pure water, juice and non-carbonated drinks. The equipment can handle both PET plastic bottles and glass containers with diameter range of 50-115mm and height of 160-320mm.

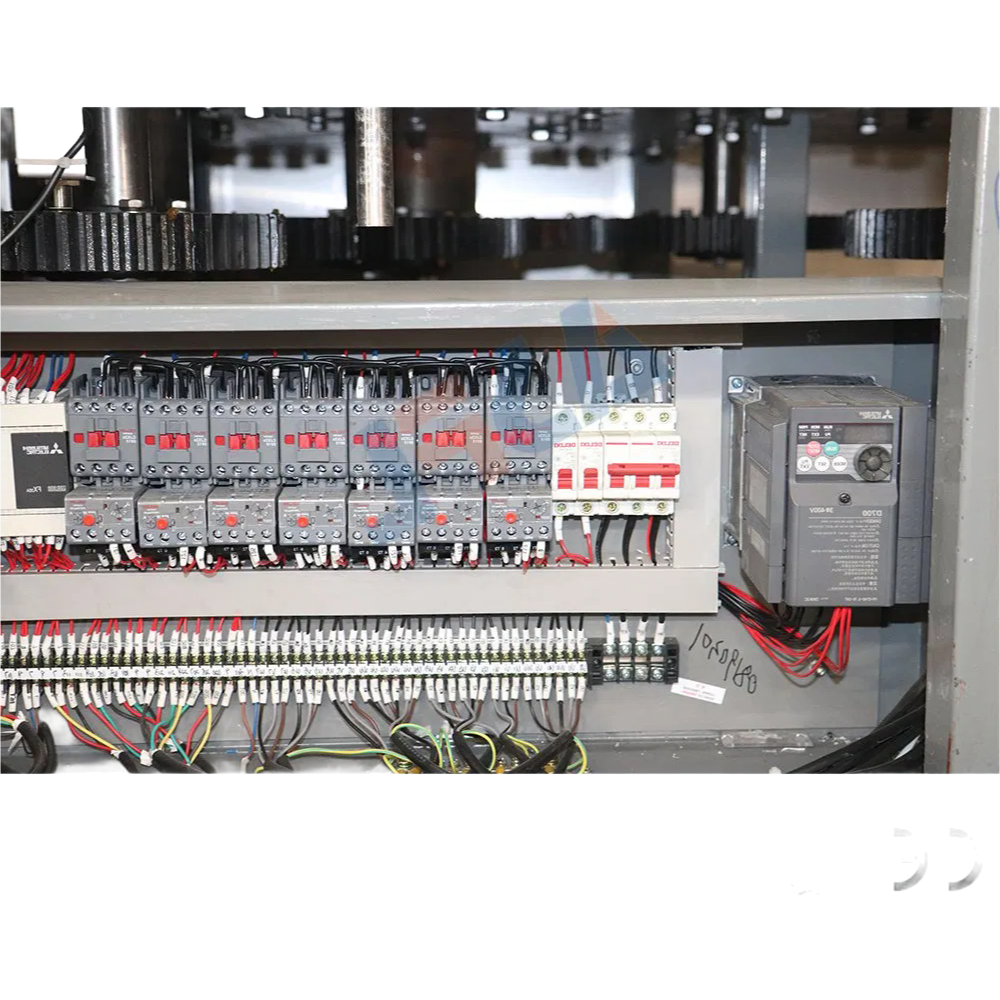

Key electrical components utilize Siemens PLC for reliable performance. The machine operates under atmospheric pressure principle with chute lifting mechanism for container positioning. Standard configurations include aseptic water rinsing system with pressure range of 0.06-0.2Mpa.

The production capacity ranges from 2000 to 30000 bottles per hour (based on 500ml containers). Multiple models are available to meet different output requirements. All liquid contact parts are made of food-grade stainless steel for hygiene and durability.

This equipment has obtained CE, ISO and SGS certifications. Factory acceptance testing includes video documentation of machine operation. The standard package uses export-grade wooden cases for safe transportation.

Delivered promptly and efficiently, the shipping process was seamless with regular updates provided throughout. The packaging was secure and professional, ensuring the equipment arrived in perfect condition without any delays or issues. From a quality perspective, the construction feels robust and durable, with a solid finish that meets expectations for industrial use. Customer service was responsive and helpful, addressing inquiries quickly and offering clear assistance when needed. Overall, a smooth experience from order to delivery, with reliable support and a product that appears well-made for its intended purpose.

Hats off to the entire team involved in getting this equipment to me. The logistics were handled with impressive precision and care. From the initial shipping notification to the final delivery, every step was communicated clearly and promptly. The packaging was robust and secure, ensuring that the heavy machinery arrived in perfect condition without a single scratch or dent. The carrier was professional and handled the unloading with expertise, which was a huge relief given the size and weight of the unit. Regarding quality, the stainless steel construction is immediately noticeable—it feels solid, durable, and built to withstand rigorous industrial use. The welds are smooth, and the overall finish is excellent, reflecting a high standard of manufacturing. As for service, the support staff were responsive and helpful, answering my pre-delivery questions quickly and thoroughly. They provided all necessary documentation and were proactive in scheduling. While I haven’t yet integrated it into my production line, the initial impressions based on logistics, apparent quality, and customer service are overwhelmingly positive. This experience has been seamless from order to arrival, setting a very high benchmark for industrial equipment procurement.

Worthy of high praise, the entire experience from ordering to delivery was seamless. The logistics were handled with impressive efficiency; the equipment arrived well ahead of the estimated schedule, which was a fantastic surprise. Every component was securely packaged, demonstrating careful attention to detail to prevent any transit damage. Upon unboxing, the build quality immediately stood out. The stainless steel construction is robust and precisely fabricated, exactly as described, promising excellent durability for our production line. Customer service was equally commendable; the support team was responsive and proactive, providing clear updates and readily available to answer preliminary questions. This combination of reliable logistics, superior material quality, and attentive service makes this supplier a highly recommended partner for essential packaging machinery.

Xcellent experience overall. The shipping was surprisingly fast and the items arrived well-packaged with no visible damage. The quality of the equipment appears robust and precisely manufactured, matching the descriptions provided. Customer service was responsive and helpful during the ordering process, answering all preliminary questions promptly. While I haven't yet integrated the machinery into our full production line for operational testing, the initial inspection is very positive. The logistical coordination was smooth, and all necessary documentation was clear. Based on these initial factors of delivery speed, packaging integrity, and professional communication, I am optimistic about the product's performance. The supplier seems reliable, which is crucial for such industrial purchases. The entire pre-delivery phase was handled efficiently, leaving a good impression.

Hats off to the entire team for a truly seamless experience from start to finish. The logistics were handled with impeccable precision; the equipment arrived well ahead of the estimated schedule, which was a fantastic surprise. Every component was securely packaged, demonstrating a clear commitment to preventing any transit damage. Regarding quality, the stainless steel construction is immediately impressive—robust, polished, and clearly built for industrial durability. It exudes a sense of reliability that is essential for our production line. The service provided was equally outstanding. The support staff was proactive, offering clear documentation and being readily available to answer preliminary questions. Communication was consistent and professional throughout the entire process. This level of attention to detail in logistics, the evident superior craftsmanship of the machine, and the exceptional customer service have collectively made this a highly satisfactory procurement. We felt valued as a client every step of the way.

Naturally, the delivery was remarkably swift and well-coordinated. The logistics team ensured the equipment arrived precisely on schedule, with every component securely packaged to prevent any transit damage. The overall quality of the stainless steel construction is immediately apparent; it feels robust and precisely engineered for durability in a demanding production environment. Regarding service, the communication from the sales and support team was consistently clear, professional, and helpful throughout the entire process, from initial inquiry to post-delivery follow-up. They were proactive in providing necessary documentation and were readily available to answer questions. This combination of efficient logistics, solid build quality, and attentive customer service made for a very smooth and satisfactory procurement experience. The equipment itself was exactly as described and depicted, arriving in perfect condition ready for integration into our line.

Hats off to the team for a truly seamless experience from start to finish. The logistics were handled with impeccable precision; the equipment arrived exactly on the scheduled date, well-packaged and secure, with no delays or complications whatsoever. The quality of the stainless steel construction is immediately apparent—robust, polished, and clearly built to industrial standards, promising excellent durability for our juice and carbonated drink lines. What truly stood out, however, was the exceptional service. The communication was proactive, clear, and helpful at every stage, from the initial inquiry to the post-delivery follow-up. Any questions we had were addressed promptly and thoroughly by a knowledgeable and courteous support team. This level of professional service instills great confidence in both the product and the company behind it. Overall, an outstanding transaction that perfectly balanced efficient logistics, superior material quality, and top-tier customer support.

Needed a machine for our new juice line and this stainless steel filler arrived incredibly fast. The shipping company provided clear tracking updates, which was a relief. Upon unboxing, the build quality immediately stood out. The welds are smooth and the steel has a great finish, feeling very solid and professional. Communication with the seller was prompt and helpful throughout the process. They answered all my preliminary questions about specifications before I even placed the order. While I haven't integrated it into the full packaging line yet, the initial setup and test run were straightforward. The overall impression from logistics to the physical product and the support received has been very positive. It seems like a reliable piece of equipment that should serve our production needs well. The packaging was also secure, with no signs of damage during transit, which is always a major concern with heavy machinery.

Came across this company while sourcing equipment for our new beverage line. The entire process, from initial inquiry to final delivery, was handled with impressive professionalism. Communication was clear and timely throughout, which is crucial for such a significant capital investment. Regarding logistics, the shipment arrived exactly within the estimated timeframe provided. The packaging of the equipment components was exceptionally secure, with robust crating and ample protective materials. There was no sign of damage or mishandling during transit, which speaks volumes about their diligence in preparing shipments. Unpacking was straightforward, and all parts were clearly labeled and accompanied by comprehensive packing lists. The quality of the stainless steel construction is immediately apparent. The welds are smooth and clean, and the finish is consistent and high-grade. It has the substantial feel of industrial machinery built to last. All the fittings and connection points appear precise. While we have not yet begun operational testing, the initial build quality inspection leaves us very confident. The service aspect has been outstanding. Their technical sales team was knowledgeable and did not apply excessive pressure. They took the time to understand our specific throughput requirements and application for juice and carbonated drinks. The documentation provided, including manuals and basic schematics, is thorough and well-organized. They have been responsive to our preliminary questions as we prepare for installation. Overall, this first phase of dealing with the supplier—focusing on the procurement, shipping, and initial quality assessment—has been highly positive. They have established a strong foundation of trust. Careful logistics management, apparent material and manufacturing quality, and proactive, informative service characterize the experience so far. We look forward to commissioning the equipment and hope the operational performance matches the excellence demonstrated in these initial stages.