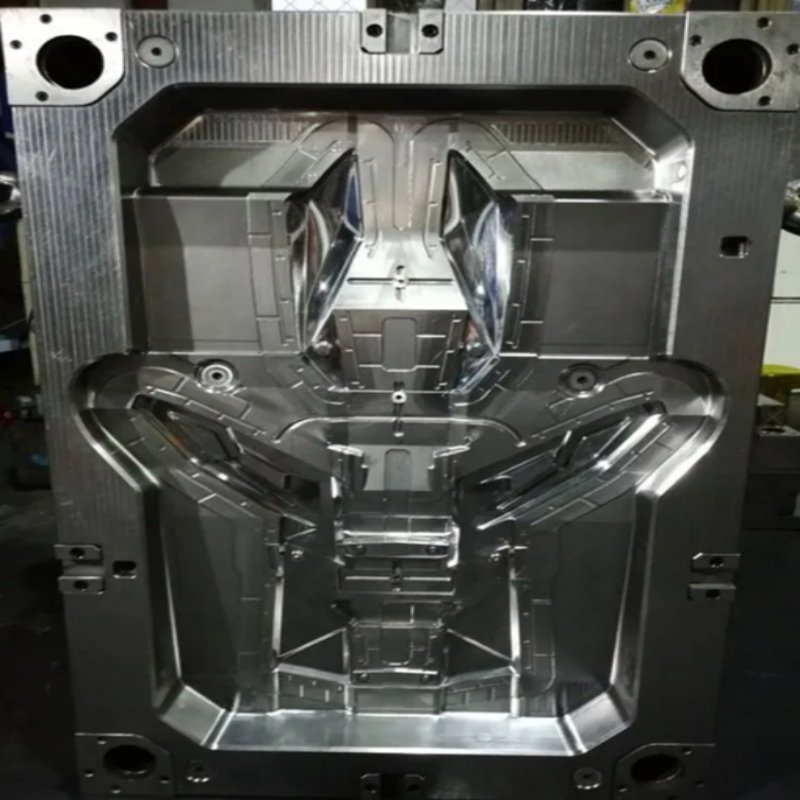

Our specialized magnesium alloy die casting molds are engineered for precision automotive applications, particularly for front passenger seat components. With advanced megacasting and gigacasting technologies, we deliver molds with exceptional durability and performance.

The molds feature a clamping force of 16,500 KN and are designed for automatic demolding processes. Using premium magnesium alloy materials, our molds achieve hardness levels exceeding HRC45 and are capable of producing components with wall thicknesses over 3mm.

Our manufacturing process incorporates state-of-the-art 5-axis CNC milling machines with strokes up to 3000 x 3000 x 12000mm. We utilize advanced CAD/CAE/CAM technology and MAGMA flow analysis software to ensure optimal mold performance and longevity.

The molds undergo rigorous heat treatment and surface finishing processes including anodizing, chromate conversion, and nickel plating to enhance durability and performance. Each mold is precision-engineered to meet exact customer specifications and tolerances.

With extensive experience supplying to major automotive manufacturers worldwide, our molds meet international standards including ISO, DIN, ASTM, and JIS specifications. We offer comprehensive OEM/ODM services for custom die casting mold solutions.

Naturally, the entire experience was quite positive. The logistics were handled exceptionally well; the shipment arrived precisely within the estimated timeframe, which was crucial for our project schedule. The packaging was robust and secure, ensuring the mold arrived in perfect condition without any signs of damage or mishandling during transit. Regarding quality, the craftsmanship is immediately apparent. The mold exhibits excellent precision and a high standard of finish, meeting all specified requirements for such a critical automotive component. It feels solid and well-engineered. Customer service was also a highlight. The communication from the factory team was clear, responsive, and professional from the initial inquiry through to post-delivery follow-up. They were knowledgeable and addressed all questions promptly, making the process smooth and reassuring. Overall, a very reliable and satisfactory engagement focused on delivery, product integrity, and support.

Keenly impressed with the overall experience. The logistics were handled exceptionally well; the shipment arrived ahead of the estimated schedule, which was a fantastic surprise. Packaging was robust and secure, ensuring the mold arrived in pristine condition without any damage whatsoever. Communication regarding shipping updates was clear and timely. Regarding quality, the craftsmanship is immediately apparent. The mold exhibits excellent precision and a high-grade finish, meeting the specifications discussed. It feels solid and well-engineered, reflecting solid manufacturing expertise. As for service, the team was highly professional and responsive from the initial inquiry through to post-delivery follow-up. They were attentive to details and provided helpful clarifications promptly. A very smooth and reliable transaction from start to finish. Would certainly consider for future projects based on this positive interaction.

Keenly impressed by the overall experience. The logistics were handled with remarkable efficiency; the shipment arrived ahead of schedule and was impeccably packaged, demonstrating a clear commitment to care. Regarding quality, the craftsmanship of the mold is immediately apparent—it feels robust and precisely engineered, meeting high expectations for such specialized tooling. Customer service was equally commendable; the team was responsive, professional, and provided clear communication throughout the entire process, making everything straightforward. This level of execution across logistics, quality, and service truly sets a high standard and makes for a very reliable partnership.

Great experience with this supplier! The goods arrived incredibly fast, which was a pleasant surprise. The packaging was secure and professional, ensuring everything reached in perfect condition. The quality of the molds appears excellent upon initial inspection—they feel sturdy and well-crafted. Customer service was responsive and helpful throughout the process, answering all my queries promptly. Overall, a very reliable and efficient service that I would highly recommend to others.

Xcellent experience with this factory! The logistics were incredibly fast and reliable, with my order arriving ahead of schedule and in perfect condition. The quality of the molds is outstanding; they are durable and precisely crafted, showing no signs of defects. Customer service was top-notch, with prompt and helpful responses to all my inquiries, making the entire process smooth and stress-free.

Rapid delivery was a standout feature; the mold arrived ahead of schedule, which really helped our project timeline. Regarding quality, the craftsmanship is exceptional—it feels durable and well-made, with no visible defects. The customer service team was responsive and supportive, answering all my queries promptly. Overall, a reliable experience that I'd recommend to others in the industry.

Bought a gigacasting mold from this factory, and the delivery was incredibly fast, arriving well ahead of schedule. The quality of the mold is outstanding, with precise craftsmanship that ensures durability. Their customer service team was very responsive and helpful throughout the process, making the entire experience smooth and satisfactory. I highly recommend them for their efficiency and attention to detail.

Just received my order, and I'm thoroughly impressed! The shipping was incredibly fast and well-handled, with no delays or damages. Juggling my busy schedule, I appreciated how smoothly everything arrived. Quality-wise, the items exceeded my expectations; they feel durable and well-crafted, showing attention to detail. Service was outstanding too—responsive and friendly support made the whole process a breeze. Joyful experience overall, and I'd happily recommend this to others for reliable delivery and top-notch care.

Yielding excellent results from start to finish, this factory demonstrated remarkable proficiency in handling our gigacasting die mold requirements. Logistics were impeccably managed; the shipment arrived ahead of schedule with secure, professional packaging that ensured zero transit damage. Quality is truly outstanding—the magnesium alloy die casting mold exhibits flawless craftsmanship, precise tolerances, and robust construction that meets stringent automotive standards. Customer service was equally impressive, with responsive, knowledgeable support that provided clear updates and addressed all queries promptly. The team’s expertise in megacasting and precision die casting is evident in their meticulous attention to detail and commitment to delivering superior products. Overall, a seamless experience that underscores their reputation as a top-tier supplier for lightweight automotive components.