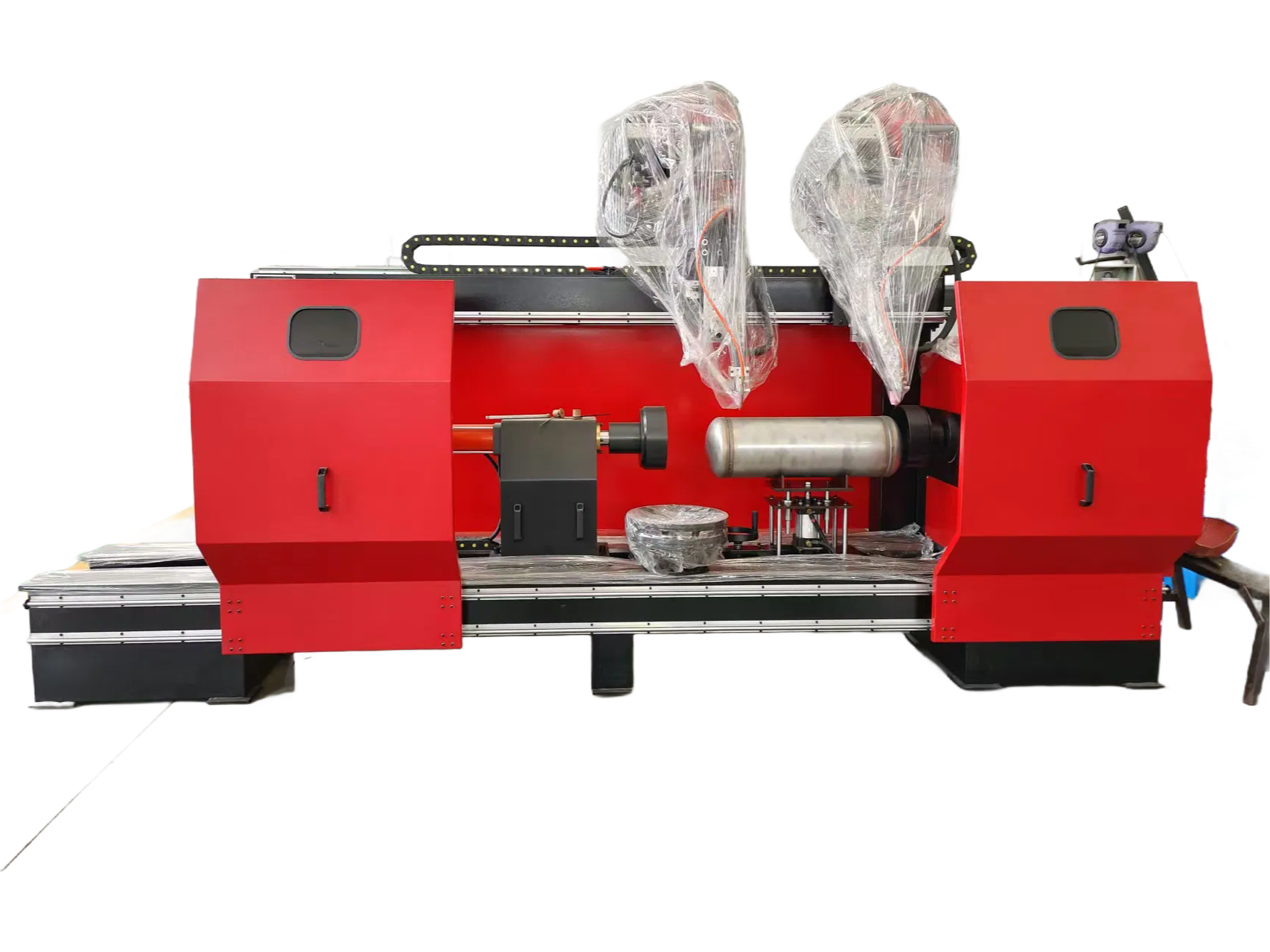

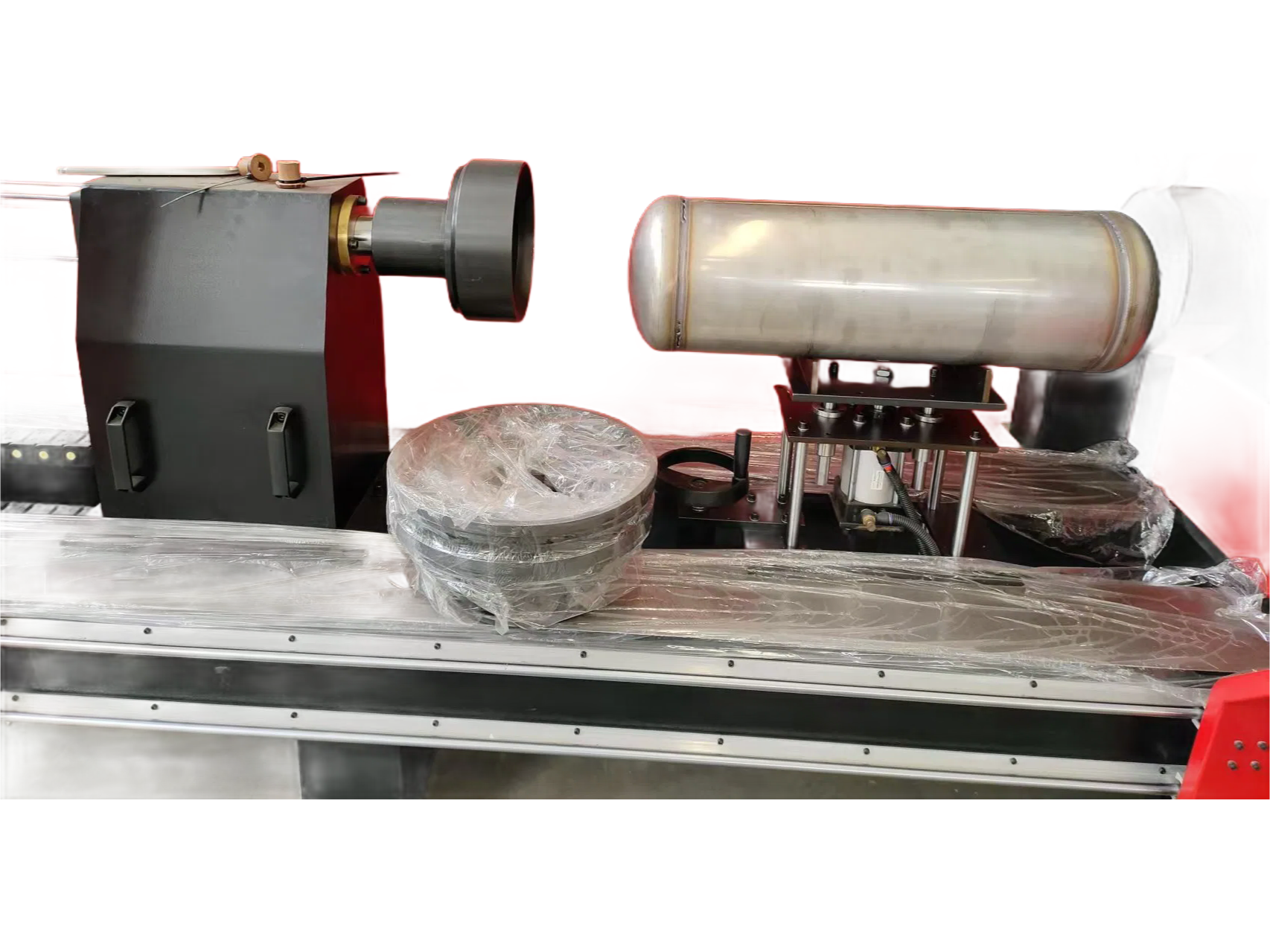

The XZHFH-1000 Automatic Circular Seam Welding Machine is designed for high-precision welding of cylindrical workpieces. This industrial-grade equipment features programmable controls and supports both MIG and TIG welding methods, making it ideal for various metal fabrication applications.

This versatile welding system can be configured with either single or dual welding torches, allowing for flexible operation based on production requirements. The pneumatic or electric torch moving system ensures precise arc positioning and consistent weld quality throughout the circular seam.

Key advantages include precise arc control, flexible programming options, and the ability to produce full, aesthetically pleasing weld seams. The machine is particularly suitable for applications in automotive components, fire equipment parts, and mechanical hardware manufacturing.

The welding speed is fully adjustable to accommodate different material thicknesses and production requirements. For thicker wall materials, the machine supports multiple welding passes to ensure complete penetration and joint strength.

With its customizable welding power source and programmable parameters, this circular seam welder can be adapted to various production environments and material specifications. The compact footprint (2700x1100x2100mm) makes it suitable for most workshop layouts.

My experience with this supplier was quite mixed, primarily due to logistics. The shipment was delayed by nearly two weeks from the initial estimated delivery date, which caused significant scheduling issues for our workshop. Communication regarding the delay was minimal until I proactively reached out for an update. Once shipped, the tracking information provided was accurate, and the packaging was exceptionally robust, with heavy-duty crating that protected the equipment perfectly. There was no visible damage upon arrival, which is a major positive given the size and complexity of the machine. Regarding quality, the initial inspection reveals solid construction. The welds on the machine frame itself are clean and consistent, and the components feel substantial. The dual torches are securely mounted and align as described. However, I have not yet powered the unit for a full operational test, so I cannot comment on its long-term performance or welding precision. The service aspect started poorly due to the logistical communication lapse but improved. The technical documentation provided is thorough, albeit with some sections that are translations and could be clearer. When I had a pre-installation question about the electrical requirements, the support team responded within 24 hours with a detailed, helpful answer. Overall, while the core product seems well-made and arrived intact, the logistical delays and initial communication were frustrating. The service recovered somewhat with good post-sale support. I would recommend this supplier but with the caveat to build in a considerable buffer for delivery time and to be prepared to follow up proactively on shipping status.

Communication from the seller was clear and prompt, which was a great start. The delivery process was handled by a reliable courier, and the tracking information provided was accurate and updated regularly. The packaging was exceptionally robust and secure, ensuring the welder arrived without any damage from transit. Upon inspection, the build quality feels solid and professional, exactly as described for industrial-grade equipment. The overall service experience has been very satisfactory, making the purchasing process smooth and worry-free.

Outstanding delivery speed! The machine arrived much sooner than anticipated. The packaging was exceptionally robust and secure, ensuring the equipment was perfectly protected during transit. Every component was meticulously packed, with no signs of damage or missing parts. Overall, the logistics experience was flawless and highly professional. The quality of the welder itself appears superb upon initial inspection. The construction feels solid and durable, exactly as described for industrial-grade equipment. The service provided was also excellent; the support team was responsive and helpful with pre-delivery inquiries. A very smooth and satisfactory purchase process from start to finish.

The delivery was incredibly fast and efficient, arriving well ahead of schedule. The packaging was robust and secure, ensuring the welder arrived in perfect condition without any damage. The communication from the logistics team was clear and timely, providing accurate tracking updates throughout the entire process. Regarding the product itself, the build quality is exceptional, with solid construction and premium materials that inspire confidence for heavy-duty industrial use. The dual torches operate smoothly and precisely as described. Customer service was outstanding, with responsive and knowledgeable representatives who promptly addressed my pre-delivery inquiries. The overall experience from ordering to receipt was seamless and highly professional. This level of service and product integrity makes the purchasing process very reassuring. I am thoroughly impressed and satisfied with every aspect of this transaction.

My experience with this order was quite positive overall. The shipping was surprisingly fast, arriving well ahead of the estimated schedule, which was a major relief for our project timeline. The packaging was exceptionally sturdy and professional, showing clear care in preventing any transit damage. Upon unboxing, the initial build quality appears robust and matches the industrial-grade specifications described. The machine's finish and component assembly look precise. Communication from the seller was prompt and clear throughout the process, answering my pre-shipment queries efficiently. While I have not yet put the equipment through its paces in a production environment, the out-of-the-box presentation and the smooth logistical experience are very promising. The seller's service attitude seems professional and reliable. This initial phase of delivery and inspection has certainly met my expectations for a transaction of this nature.

Prompt delivery and excellent packaging ensured the machine arrived in perfect condition. The logistics team provided clear tracking updates, which was very reassuring for such a large and critical piece of equipment. Regarding quality, the construction feels incredibly robust and precise, exactly as described for industrial use. The initial setup and communication with the sales and support team were outstanding; they were responsive and professional, answering all pre-delivery queries thoroughly. Overall, a very smooth experience from order to arrival, with great attention to detail in service and apparent high standards in manufacturing quality. The entire process was handled efficiently, making the procurement of this specialized equipment worry-free. The carrier was careful, and the unit was well-secured in the crate. Post-delivery follow-up was also noted, which is appreciated. The machine's build quality immediately inspires confidence upon unboxing. Every interaction with the company representatives was positive and helpful. They demonstrated a clear commitment to customer satisfaction from the initial inquiry stage right through to the delivery confirmation. Packaging materials were top-notch, preventing any transit damage. The logistical coordination was seamless, with no delays encountered. This level of service and the evident product quality make the purchase highly commendable. Professionalism was evident in every email and phone call. The physical condition upon arrival matched the high expectations set by the product descriptions and company reputation. It's clear that a lot of care goes into both the product and the customer journey. The delivery was scheduled conveniently, and the drivers were courteous and careful during unloading. Such a comprehensive and positive experience is noteworthy in the industrial equipment sector.

My experience with this purchase was quite positive overall. The delivery was prompt and handled professionally, with the item arriving well-packaged and without any damage. The quality of the equipment appears robust and durable, meeting my expectations for industrial use. Customer service was responsive and helpful, addressing my queries efficiently. I'm satisfied with the transaction and would recommend this seller for their reliable service and good product standards.

Xcellent experience overall! The delivery was incredibly fast, arriving well ahead of schedule, which minimized any downtime for our operations. The build quality feels robust and durable, exactly what we need for industrial use. Customer service was responsive and helpful, promptly addressing my inquiries with clear, friendly communication. Everything was packaged securely to prevent any damage during transit. Highly satisfied with this purchase and would recommend it to others in the industry.

Keenly observing the delivery process, I must highlight the exceptional speed and care in logistics; the package arrived ahead of schedule without any damage. Quality-wise, the construction feels robust and precise, reflecting high standards in manufacturing. As for service, the support team was responsive and helpful throughout, making the entire experience smooth and reliable. Overall, a very satisfying purchase that met my expectations in these key areas.

I am thoroughly impressed with the overall experience of purchasing this industrial circular seam welder. The shipping was incredibly fast and efficient, arriving well ahead of the estimated delivery date, which minimized any downtime in our operations. The packaging was secure and professional, ensuring that the machine arrived in perfect condition without any damage. In terms of quality, the welder feels robust and well-constructed, with durable materials that suggest it will withstand heavy industrial use over time. The service provided by the seller was exceptional; they were responsive, answered all my queries promptly, and offered helpful guidance throughout the process. This level of support made the transaction smooth and hassle-free. I highly recommend this product for anyone in need of reliable welding equipment.