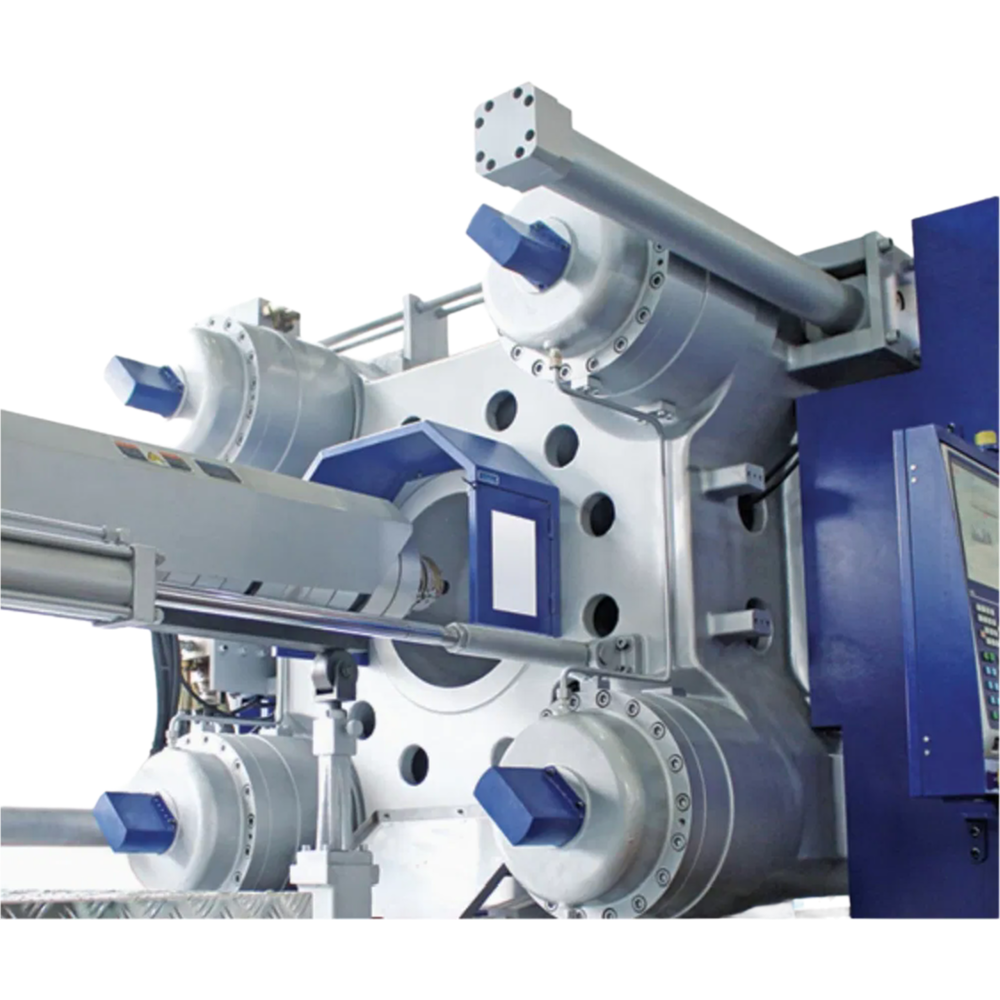

The two-platen injection molding machine is a versatile and efficient solution for manufacturing a wide range of plastic products across multiple industries. It is designed to handle thermoplastic materials with precision and reliability, making it suitable for both small and large-scale production needs.

This machine is widely used in consumer electronics for producing casings, connectors, and internal components. In the automotive sector, it manufactures interior parts, functional components, and engine parts. The medical industry benefits from its ability to produce disposable supplies, equipment casings, and specialized implants. Additionally, it serves the packaging, household appliance, construction, toy manufacturing, daily necessities, aerospace, and sports equipment industries.

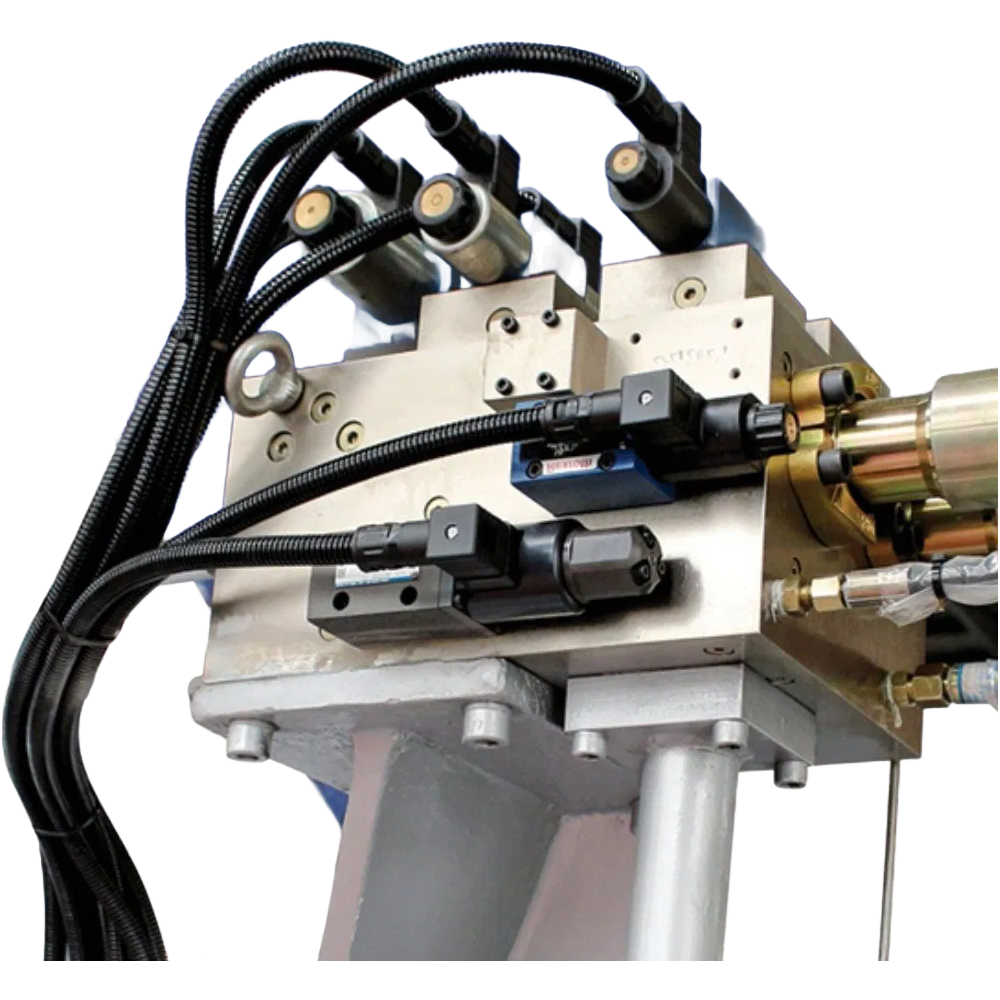

Key features include customizable opening stroke based on product requirements, agile and stable mold opening and clamping to improve cycle time, enhanced service life with reduced maintenance costs, and a strong stiffness frame platen that minimizes floor area. The machine supports multi-component molding solutions tailored to customer specifications.

Technical parameters ensure high performance, with options for maximum daylight ranging from 1750mm to 4200mm and pump maximum pressure of 21/17.5MPa. It is certified with CE and ISO9001:2008 standards, ensuring quality and safety.

Beyond expectations on delivery speed. The logistics were handled flawlessly, with clear communication at every stage. The packaging was secure and professional, ensuring everything arrived in perfect condition. Regarding quality, the build and finish of the machine are robust and precise, exactly as described. The service team was exceptionally responsive and helpful, answering all pre-delivery queries promptly. A very smooth and satisfactory transaction overall.

Naturally, the entire process from ordering to delivery was handled with impressive efficiency. The logistics were seamless, with clear communication at every stage and the machine arriving exactly as scheduled, well-packaged and without any damage. The quality of the construction is immediately apparent; it feels robust and engineered for heavy-duty industrial use. The service team was exceptionally responsive, answering all pre-delivery queries promptly and thoroughly. Overall, a very professional experience that instills confidence in the product and the company behind it.

Very impressed with the overall experience. The delivery was remarkably fast and the logistics were handled flawlessly; the machine arrived well-packaged and on schedule without any delays. Regarding quality, the construction feels robust and the initial setup went smoothly, indicating solid manufacturing standards. Customer service was also highly responsive and helpful during the ordering process, answering all preliminary questions promptly. A straightforward and positive transaction from start to finish.