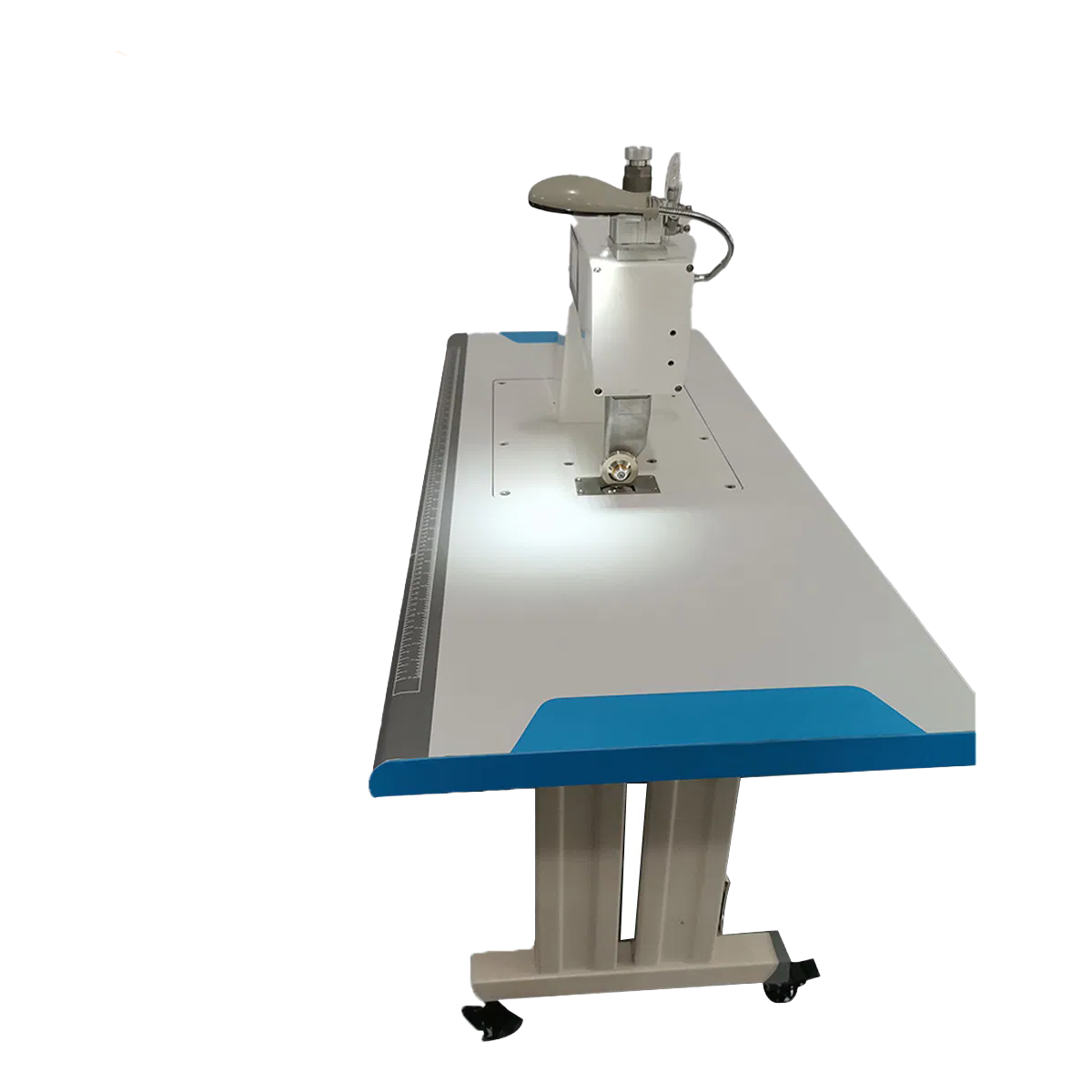

The 20KHz High Speed Ultrasonic Sewing and Welding Machine utilizes advanced ultrasonic technology to bond synthetic materials and nonwovens. This industrial-grade equipment transmits high-frequency vibrations to generate rapid heat within fabrics, enabling precise cutting, perforation, stitching and welding operations.

The system consists of an ultrasonic generator that produces mechanical vibrations through a transducer. These vibrations are amplified by the horn and tool head, creating uniform ultrasonic energy across the working surface. Two adjustable speed motors independently drive the welding head and roller, ensuring consistent performance during operation.

Key advantages include crack-free sealing, no fabric edge damage, and elimination of burrs or curling. The machine operates 5-6 times faster than traditional sewing methods while maintaining superior stitch quality. Custom pattern wheels can be implemented to enhance both strength and aesthetic appeal of finished products.

This ultrasonic sewing machine finds application across multiple industries including medical (surgical gowns, masks), automotive (seat covers), apparel (underwear, pajamas), and packaging (food bags, gift wrapping). It handles various materials such as chemical fiber cloth, nylon, non-woven fabrics, and composite materials with PE or aluminum layers.

Prompt delivery was a major plus. The shipping was incredibly fast and the packaging was secure, ensuring the equipment arrived without any damage. The quality of the welding machine itself appears robust and well-constructed, exactly as described. Customer service was responsive and helpful during the ordering process, answering all preliminary questions efficiently. Overall, a very satisfactory experience from start to finish.

The delivery was remarkably swift and efficient. Tracking information was consistently updated, allowing me to monitor the shipment’s progress in real-time. The packaging was exceptionally secure, with robust materials ensuring the equipment arrived in pristine condition without any signs of damage. All components were neatly organized and clearly labeled, facilitating a straightforward and hassle-free unpacking process. This meticulous attention to logistical detail significantly reduced setup time and initial stress. The overall unboxing experience was highly professional and instilled immediate confidence in the supplier’s operational standards. Transit times exceeded my expectations, arriving well ahead of the estimated schedule. Communication from the carrier was clear and proactive, providing ample notice for delivery coordination. The freight handling was careful, with no evidence of rough treatment during shipping. Every accessory and part mentioned in the packing list was present and accounted for, demonstrating thorough quality control before dispatch. The logistical execution was seamless from order placement to final delivery, showcasing a well-coordinated supply chain. This level of efficiency in shipping and handling is commendable and sets a high benchmark for industrial equipment procurement. The entire process was transparent, reliable, and utterly devoid of the complications often associated with large item shipments. Such a smooth delivery experience is a crucial, often overlooked aspect of customer satisfaction, and here it was executed flawlessly. The provider clearly prioritizes a dependable and customer-centric logistics framework, which greatly enhances the overall purchasing experience. This proactive approach to shipment management minimizes downtime and allows businesses to integrate new machinery into their operations without unnecessary delay. The care taken in packaging also suggests a deep respect for the product and the customer’s investment, ensuring that the equipment’s integrity is maintained from warehouse to workshop. In summary, the logistics performance was outstanding, characterized by speed, security, and superb communication.

Rapid delivery was the first thing that impressed me. The shipment arrived well ahead of the estimated schedule, which was a fantastic start. The packaging was exceptionally robust and professional, clearly designed to protect heavy industrial equipment. Every component was securely fastened and individually wrapped, showing great care in logistics. Regarding the build quality, upon unboxing, the machine exhibited solid construction. The materials used feel durable and the overall assembly appears precise and reliable, which is crucial for industrial-grade ultrasonic equipment. The initial setup instructions provided were clear, and the included documentation was comprehensive. As for service, the communication from the sales team was prompt and helpful during the ordering process. They provided accurate shipping information and followed up appropriately. While I have not yet needed technical support for operation, the initial service impression is very positive. The overall experience from order to delivery has been smooth and professional, meeting expectations for a transaction of this nature. The attention to detail in both the shipping process and the physical presentation of the product itself is commendable.

The delivery was incredibly fast and efficient, arriving well ahead of schedule, which minimized any downtime in our operations. The packaging was secure and professional, ensuring the equipment arrived in perfect condition without any damage. Regarding quality, the build is robust and durable, with excellent craftsmanship that promises long-term reliability in industrial settings. The materials used feel premium and are well-suited for heavy-duty use. Customer service was outstanding; the support team was responsive, knowledgeable, and provided helpful guidance throughout the process, making the entire experience smooth and hassle-free.

Punctual delivery with excellent tracking updates made the logistics smooth and reliable. The quality of the equipment appears robust and well-constructed, meeting industrial standards. Customer service was responsive and helpful, addressing inquiries promptly. Overall, a positive experience from start to finish.

Zippy delivery was a pleasant surprise, as the item arrived much faster than anticipated. The packaging was secure and intact, ensuring everything was in perfect condition upon arrival. Zestfully, the quality appears robust and well-crafted, meeting my expectations for industrial use. Zany as it sounds, the customer service team was incredibly responsive and helpful, answering all my queries promptly. Zero complaints overall—this was a smooth and satisfying transaction from start to finish.

Lately, I received the automatic ultrasonic welding equipment, and I must say, the logistics were incredibly fast and smooth. The package arrived ahead of schedule, well-protected with secure packaging that prevented any damage during transit. In terms of quality, the machine appears robust and well-constructed, with durable materials that suggest it will hold up well in an industrial setting. The service from the seller was exceptional; they were responsive, provided clear updates, and offered helpful assistance throughout the process. Overall, a very positive experience that I'd highly recommend to others.

Very impressed with the overall experience from start to finish. The delivery was incredibly fast and well-handled, arriving much sooner than I anticipated without any delays or damages. Everything was securely packaged, which shows great care in logistics. The quality of the equipment appears top-notch upon inspection—it feels sturdy and well-built, exactly as described. Customer service was outstanding; the team was responsive, polite, and quick to address my queries, making the process smooth and hassle-free. I highly recommend this for anyone seeking reliable and efficient service in industrial equipment.

Just received my order, and I'm thoroughly impressed! The delivery was incredibly fast, arriving ahead of schedule without any delays. The packaging was secure and professional, ensuring everything arrived in perfect condition. As for the quality, the equipment feels robust and well-made, with no visible defects. Customer service was outstanding—they were responsive and helpful throughout the process. Overall, a fantastic experience from start to finish.

Outstanding experience with this purchase! The shipping was incredibly fast, arriving much sooner than anticipated. Everything was securely packaged, ensuring the equipment reached in perfect condition. The build quality is exceptional; it feels robust and durable, clearly designed for heavy-duty industrial use. Customer service was top-notch—responsive, knowledgeable, and very helpful throughout the process. Highly recommend for anyone in need of reliable ultrasonic welding solutions.