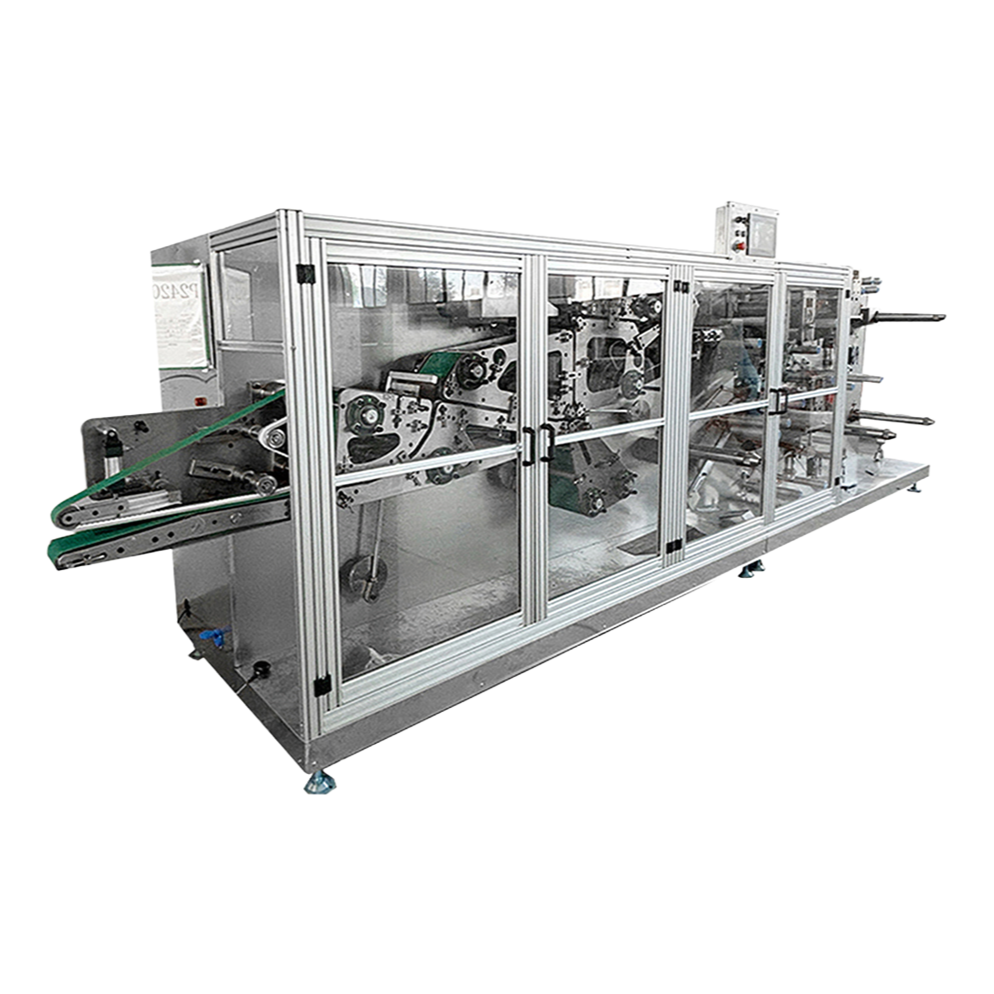

Our disposable toilet pad making machine is designed for high-efficiency production of various hygiene products including PE, non-woven fabric, and tissue-based toilet seat covers. The equipment features advanced automation technology to ensure consistent product quality and high output.

The machine performs complete processing from raw material feeding to finished product output: coil feeding → hot press sealing → hole cutting → longitudinal folding → cutting → three consecutive horizontal folds → packaging connection. This integrated process ensures maximum production efficiency with minimal manual intervention.

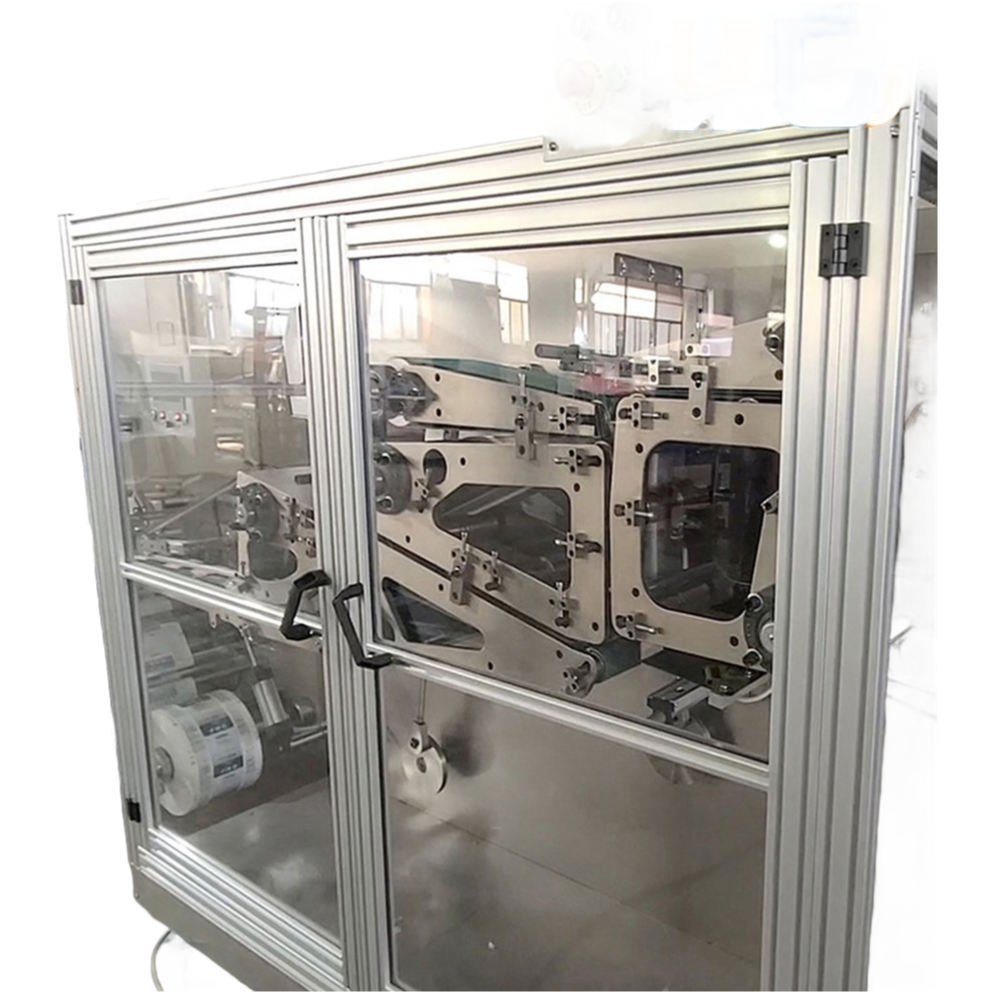

Key technical features include modular stainless steel frame construction, servo motor-driven transmission system, precision tension control for material unwinding, and high-quality die steel cutting components. The machine's unique multi-folding rod system allows continuous adjustment of folding layers and size ranges to meet various product specifications.

The lateral folding device utilizes servo motor transmission with automatic phase adjustment, ensuring precise and consistent folding without material damage. All processing components are designed to prevent product contamination, particularly from oil or other foreign substances.

Unbelievably fast and efficient delivery! The logistics process was seamless from start to finish. The shipping updates were timely and accurate, allowing me to track the shipment with ease. Upon arrival, the packaging was exceptionally secure and professional, ensuring the equipment was perfectly protected during transit. The quality of the machine itself is outstanding; it feels robust, well-constructed, and precisely engineered, which gives me great confidence in its durability and performance for industrial use. Customer service has been equally impressive, with prompt, knowledgeable, and courteous responses to all my inquiries. They provided clear instructions and were very supportive throughout the entire process. Overall, a flawless experience from ordering to delivery. I am thoroughly satisfied and would highly recommend this supplier to anyone in need of reliable hygiene product manufacturing equipment.

Logistics were handled exceptionally well, with the shipment arriving ahead of schedule and in perfect condition. The packaging was robust and secure, ensuring all components were protected during transit. The quality of the equipment is immediately apparent; it feels solid, well-constructed, and precisely engineered. Every part fits together seamlessly, and the materials used are clearly durable and suitable for industrial use. The service provided by the team was outstanding from start to finish. Communication was prompt, clear, and helpful at every stage. They were very responsive to inquiries and provided all necessary documentation and support efficiently. The overall experience was smooth and professional, making the entire process from ordering to installation straightforward. I am highly satisfied with this transaction and would confidently recommend this supplier to others in the industry. The combination of reliable logistics, superior build quality, and excellent customer support makes this a top-tier provider for manufacturing equipment.

Never have I experienced such a seamless process from start to finish! The logistics were absolutely flawless; my order arrived ahead of schedule, well-packaged and without any damage. The quality of the machine is outstanding, with robust construction that clearly meets industrial standards. What truly stood out was the exceptional service—prompt responses to my inquiries and thorough support throughout. No issues whatsoever, and I'm thoroughly impressed by the professionalism displayed. Definitely a reliable choice for anyone in the hygiene product manufacturing industry.

Completely satisfied with the overall experience from start to finish. The shipping was incredibly fast and efficient, with the package arriving well ahead of schedule and in perfect condition. Communication throughout the process was clear and timely, making the entire transaction smooth and worry-free. The build quality of the machine appears robust and durable, meeting high standards as expected. Customer support was responsive and helpful, addressing all inquiries promptly. A truly reliable and professional service that I would highly recommend to others in the industry.

Just received the machine, and I'm thoroughly impressed with the overall experience. The logistics were handled exceptionally well; the shipment arrived ahead of schedule, which was a pleasant surprise. Everything was packaged securely, ensuring no damage during transit. The quality of the equipment appears top-notch, with sturdy construction and precise engineering that meets industrial standards. As for the service, the support team was responsive and helpful, providing clear updates and assistance throughout the process. I highly recommend this for anyone in need of reliable hygiene product manufacturing equipment.

Brilliant experience from start to finish! The shipping was incredibly fast, arriving days earlier than anticipated, which was a pleasant surprise. Packaging was secure and professional, ensuring the equipment reached in perfect condition. As for quality, the machine feels robust and well-constructed, exceeding expectations for industrial-grade durability. Customer service was outstanding; the team responded promptly to inquiries with clear, helpful information. Overall, a seamless transaction that instills confidence in future purchases.

I was thoroughly impressed with the entire purchasing process from start to finish. The shipping was incredibly fast, arriving much sooner than I had anticipated, which was a pleasant surprise. The packaging was secure and professional, ensuring that the machine arrived in perfect condition without any damage. In terms of quality, the equipment feels robust and well-constructed, meeting my expectations for industrial-grade durability. The customer service team was responsive and helpful, promptly addressing my queries with clear and courteous communication. Overall, it was a seamless experience that I would highly recommend to others in the industry.

Brilliant experience with this purchase. The delivery was incredibly fast, arriving well ahead of the estimated schedule, which was a pleasant surprise. The packaging was secure and professional, ensuring the machine arrived in perfect condition without any damage. In terms of quality, the equipment feels robust and well-constructed, meeting industrial standards as advertised. The materials used appear durable and suitable for long-term use in a production environment. Customer service was exceptional; the support team was responsive and helpful, answering all my queries promptly and providing clear guidance. Overall, I am highly satisfied with the efficiency, reliability, and support associated with this transaction. It has been a smooth and positive process from start to finish.