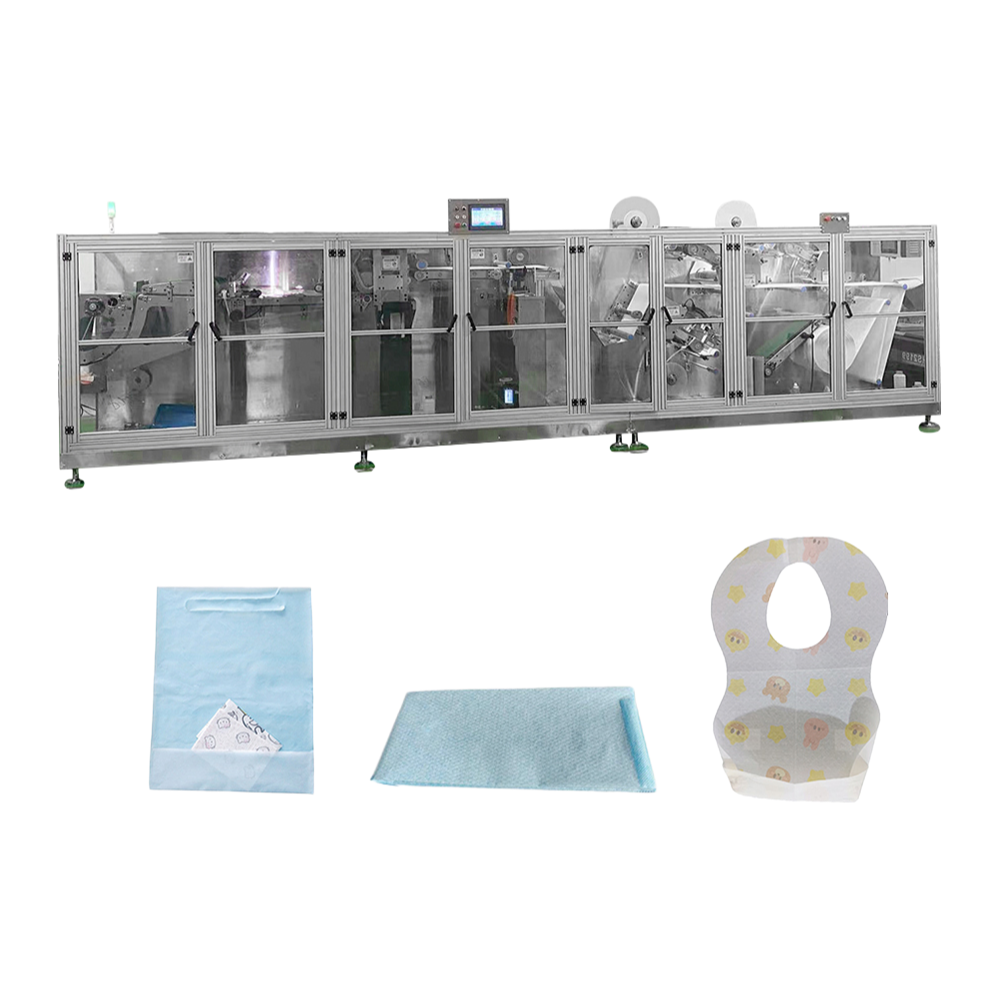

Our full automatic baby bibs making machine is designed for high-efficiency production, catering to both adult and baby bib manufacturing needs. This machine ensures precise and consistent output with advanced features such as servo motor control, heat sealing, and customizable folding options. It is built for industrial use, providing reliability and durability in various production environments.

The equipment process flow includes raw material unwinding, longitudinal wrap, edge sealing, cutting and binding break, longitudinal double folding, transverse cut, transverse fold, and finished product output. Each step is optimized for minimal waste and maximum efficiency, ensuring high-quality bibs with smooth edges and accurate dimensions.

Key components include a feeding rack made from high-quality national standard square steel pipe for stability, a transmission system with servo motor-driven high-precision synchronous wheels, and a material unwinding frame with servo-controlled tension. The over-lock mold is crafted from stainless steel for smooth operation, while heat sealing ensures even and firm edges. Cutting and binding breaks use durable die steel tools for clean incisions, and longitudinal folding employs multi-transition folding rods for stability.

Additional features include a roll cutting mode driven by servo motor for precise cutting lengths, horizontal folding with servo control for flat and accurate positioning, and a quality control system that prevents material damage. The product output platform includes batch prompting and progress functions, facilitating easy packaging and counting.

This machine is suitable for various raw materials with roll diameters up to 80cm and widths up to 80cm, making it versatile for different bib designs. It is an ideal solution for manufacturers seeking to enhance their production capabilities with automated, high-speed equipment.

Shipping was incredibly fast and efficient. The entire logistics process was handled with great professionalism, and the package arrived well ahead of the estimated schedule. It was securely packed, showing clear attention to detail in ensuring safe transit. Regarding the machine's quality, the construction feels solid and robust, exactly as one would expect from industrial-grade equipment. The materials used appear to be of high standard, promising durability for long-term operation. Service from the supplier has been outstanding from the initial inquiry through to post-delivery support. Communication was prompt, clear, and helpful, making the entire purchasing experience smooth and reassuring. Such a high level of customer care is commendable and greatly appreciated. Overall, a very positive experience on all fronts.

Hats off to the entire team for a truly seamless experience from start to finish. The logistics were handled with impeccable precision; the machine arrived well ahead of the projected schedule, which was a fantastic surprise. Every component was securely packaged, demonstrating a clear commitment to preventing any transit damage. Regarding quality, the construction is exceptionally robust. It feels solid and engineered for heavy, continuous use, exactly as promised for an industrial-grade piece of equipment. The service provided was outstanding. The communication was prompt, clear, and professional at every stage, from initial inquiry to post-delivery follow-up. They were very responsive to my logistical questions and provided all necessary documentation without delay. This level of attention to detail in logistics, the evident build quality, and the supportive customer service makes this a highly commendable purchase. I am thoroughly impressed and confident in this partnership.

Kicking off with the logistics, the delivery was remarkably swift and well-coordinated. Keen attention was evident in the packaging, which was robust and secure, ensuring the machine arrived in pristine condition without a single scratch. Kudos to the shipping team for their efficiency and the transparent tracking updates provided throughout the transit. Knowing the exact status alleviated any potential anxiety about such a significant industrial purchase. Kind regards to the logistics partners involved for a seamless process from dispatch to doorstep. Keeping the focus on quality, the construction of the machine is outstanding. It feels solid, durable, and precisely engineered, reflecting true industrial-grade standards. Key components are made from high-grade materials, promising longevity and consistent performance. Every weld and joint appears meticulous, and the finish is smooth and professional. Knowing that it carries CE certification adds an extra layer of confidence in its safety and compliance. It clearly meets, if not exceeds, the expectations set for a heavy-duty production unit. Kind of service received was equally impressive. The customer support team was knowledgeable, responsive, and proactive. They were keen to answer all preliminary queries and provided comprehensive documentation. Following the delivery, they checked in to ensure everything was in order and offered assistance for the initial setup. Their professionalism and willingness to help were consistently notable, making the entire acquisition process smooth and reassuring. This level of after-sales support is crucial for industrial equipment and was executed flawlessly here. Keeping all aspects in mind, from the rapid and careful logistics to the impeccable build quality and exceptional service, this experience has been thoroughly positive. It sets a high benchmark for industrial equipment procurement.

Keenly impressed with the overall experience from order to delivery. The logistics were handled exceptionally well; the shipment arrived precisely within the estimated timeframe, and the packaging was robust and secure, ensuring the equipment was perfectly protected during transit. Communication regarding shipping updates was clear and consistent, which made planning for the arrival straightforward. Regarding the machine’s quality, it is immediately apparent that this is a solid, industrial-grade piece of equipment. The construction feels durable, with heavy-duty materials and components that inspire confidence for long-term, high-volume operation. The finish and assembly are precise, reflecting strong manufacturing standards. The service provided by the team has been outstanding from the initial inquiry. They were responsive, knowledgeable, and patient in addressing all pre-purchase questions. Post-delivery support has also been proactive, with clear instructions and a willingness to assist. While I cannot comment on the specific operational parameters or performance in production yet, the foundational aspects of logistics, perceived build quality, and customer service have been thoroughly commendable. This initial phase suggests a reliable partnership with a professional manufacturer. The entire process felt smooth and professional, which is crucial when investing in significant industrial machinery. A very positive start to what I anticipate will be a productive relationship.

Fantastic experience from start to finish. The delivery was remarkably prompt and handled with the utmost care. The logistics team provided clear tracking updates at every stage, which made planning for the arrival incredibly straightforward. The packaging was robust and secure, ensuring the equipment arrived in pristine condition without a single scratch or issue. Regarding the machine’s quality, it is immediately apparent that this is a premium, industrial-grade piece of equipment. The construction feels solid and durable, with all components fitting together precisely. The finish is excellent, and it has a substantial, reliable feel that inspires confidence for long-term, high-volume operation. The service provided by the company was equally impressive. The sales team was knowledgeable and responsive, answering all preliminary questions thoroughly. Post-delivery support was proactive; they checked in to ensure everything was in order and confirmed the availability of technical assistance if needed. The documentation provided is clear and comprehensive. Overall, this was a seamless and highly satisfactory transaction. The combination of efficient logistics, exceptional build quality, and outstanding customer service makes this supplier highly recommendable for anyone in need of serious industrial equipment. The professionalism exhibited at every turn is commendable.

Hats off to the entire team for a truly seamless experience from start to finish. The logistics were handled with impeccable precision; the machine arrived well ahead of the estimated schedule, which was a fantastic and welcome surprise. Every component was securely packaged, and the crating was clearly done with great care to withstand international shipping. Upon unboxing, the build quality immediately stood out. The machine has a solid, robust construction that exudes durability and industrial-grade reliability. The welding, the finish on the metal surfaces, and the overall assembly speak volumes about the manufacturing standards upheld. It feels like a piece of equipment built to last for years of demanding production. Furthermore, the service provided was nothing short of exceptional. The pre-sales communication was thorough and patient, with all my technical queries addressed promptly and clearly. The documentation provided is comprehensive and well-organized. Although we are in the early stages of setup, the post-sales support team has already been proactive in checking in and offering assistance. This level of attentiveness is rare and greatly appreciated. While I cannot yet comment on the long-term operational performance, the initial impressions regarding the physical product and the professional conduct of the company are overwhelmingly positive. The combination of efficient logistics, superior apparent quality, and outstanding customer service makes this a highly commendable purchase. It instills a strong sense of confidence in both the equipment and the partnership with the manufacturer.

Wow, the delivery was incredibly fast and efficient, arriving well ahead of schedule, which minimized our downtime. The packaging was secure and professional, ensuring the machine arrived in perfect condition without any damage. In terms of quality, the construction feels robust and durable, with solid materials that suggest long-term reliability in an industrial setting. The service team was outstanding, providing clear communication and prompt support throughout the ordering process, making the entire experience smooth and hassle-free. Overall, I'm thoroughly impressed and would highly recommend this for anyone needing reliable equipment.

Never have I experienced such a seamless process from start to finish. The logistics were handled impeccably, with the machine arriving ahead of schedule and in perfect condition. The quality of the equipment is outstanding, built to last with robust materials that inspire confidence. Additionally, the customer service team was incredibly responsive and helpful, addressing all my queries promptly. Overall, a top-notch experience that I would highly recommend to others in the industry.

Zippy delivery and excellent packaging ensured the machine arrived safely without any delays. The build quality is robust and durable, meeting industrial standards perfectly. Customer service was highly responsive and supportive throughout the process, making the entire experience smooth and hassle-free.

Never have I experienced such a seamless process from start to finish. The delivery was incredibly fast, arriving well ahead of schedule, which minimized any downtime for our operations. The packaging was robust and secure, ensuring the equipment arrived in pristine condition without a single scratch. As for quality, the machine's construction is outstanding, with durable materials that promise long-term reliability. It feels solid and well-engineered, meeting our high expectations for industrial use. On the service front, the support team was exceptional—they were responsive, knowledgeable, and went above and beyond to address my inquiries promptly. Overall, a fantastic experience that I would highly recommend to others in the industry.