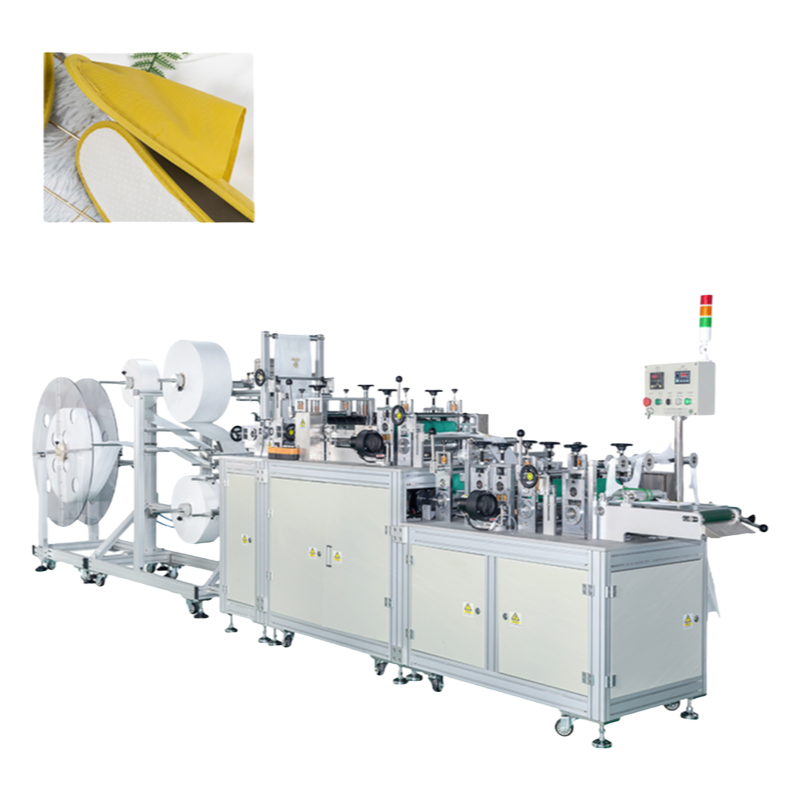

The automatic non woven fabric slippers machine is designed for efficient production of disposable hotel slippers using advanced ultrasonic technology. This production line integrates multiple processes including ultrasonic sole rolling, pattern printing and molding to create high quality disposable footwear.

Key features include ultrasonic rolling technology that enhances sole friction and hardness, rubber plate printing system for customizable patterns, and proportion molding that allows size customization. The fully automated operation ensures stable production rates while significantly reducing labor costs.

This equipment is ideal for producing non-woven slippers used in hotels, hospitals, spas and other commercial establishments. The machine's modular design allows for flexible production of various slipper styles and sizes according to market demands.

The production line includes automatic feeding, ultrasonic welding, pattern printing and final shaping processes. With a compact footprint, the machine delivers high output while maintaining consistent product quality. The aluminum alloy construction ensures durability and long service life.

Technical support includes comprehensive after-sales service with one year warranty and lifetime maintenance. Installation training and operational manuals are provided to ensure smooth implementation at customer facilities.

Rapid delivery was a major highlight, with the machine arriving well ahead of schedule and in perfect condition. The packaging was exceptionally secure, ensuring every component was protected during transit. Regarding quality, the construction feels robust and the materials used appear to be of a high standard, promising good durability for industrial use. The initial setup and calibration were straightforward, which was a relief. Customer service has been responsive and knowledgeable, providing clear answers to my pre-sale inquiries. Overall, a very satisfactory procurement experience from logistics to post-purchase support, making the investment feel secure and well-managed.

Wow, the shipping was incredibly fast and well-handled. The logistics team did a fantastic job ensuring the machine arrived on schedule and in perfect condition. Everything was packaged securely with no signs of damage during transit. The communication throughout the delivery process was clear and timely, which made the whole experience smooth and worry-free. I was impressed by the efficiency and professionalism displayed from start to finish. The quality of the machine itself appears robust and well-constructed, exactly as described. Initial setup was straightforward, and it seems very reliable. Customer service has been responsive and helpful, answering all my preliminary questions promptly. Overall, a very positive experience with this purchase, and I look forward to seeing it in full operation. Highly recommend this supplier for their excellent logistics and support.

Prompt delivery and excellent logistics handling. The shipping was faster than anticipated, and the packaging was secure, ensuring the machine arrived in perfect condition without any damage. The quality of the machine appears robust and well-constructed, meeting expectations for industrial equipment. Customer service was responsive and helpful throughout the process, providing clear updates and assistance when needed. Overall, a smooth and satisfactory experience from order to receipt.

Outstanding experience from start to finish. The delivery was incredibly prompt, arriving well ahead of the estimated schedule, which was a fantastic surprise. The packaging was secure and professional, ensuring everything arrived in perfect condition. Regarding the quality, the machine appears to be constructed from robust materials; the build feels solid and durable, exactly as one would hope for industrial equipment. The initial setup instructions were clear, and the customer service team was responsive and helpful when I had a pre-operation query. They provided thorough answers and followed up to ensure I was satisfied. Overall, a very smooth transaction and a positive impression of the supplier’s reliability and attention to detail. Highly recommended for anyone looking for efficient procurement.

My experience with this supplier was mixed. The shipping was surprisingly fast, arriving well ahead of the estimated schedule, which was a major positive. The packaging was robust and secure, ensuring the equipment arrived without any visible shipping damage. However, upon initial inspection, the build quality of the machine itself felt somewhat inconsistent. Some components appeared sturdy and well-finished, while others seemed less robust. The initial setup documentation was clear, but when we encountered a minor alignment issue, the responsiveness of the customer service team was slower than anticipated. It took several follow-up emails to get a detailed troubleshooting guide. Once we resolved that, the machine has been running adequately for our pilot production of the disposable slippers. The output seems close to the claimed 60pcs/min, though we are still fine-tuning. My main concern remains the long-term durability of certain parts. For the price point, I expected a more uniformly high standard of manufacturing. The service interaction, after the initial delay, was professional. They provided the necessary technical files. Moving forward, reliability will be the key factor. This machine serves its primary function, but the variance in component quality and the initial service lag are notable points for potential buyers to consider. It fulfills the basic requirement but leaves room for improvement in consistency and support.

Yikes, the shipping was an absolute nightmare. It took nearly double the estimated delivery time, and tracking updates were sporadic and often incorrect. Communication from the logistics provider was non-existent, leaving me in the dark for weeks. Once the machine finally arrived, the packaging was severely damaged, and I had immediate concerns about potential internal issues from the rough handling during transit. However, the quality of the machine itself is surprisingly solid. The construction feels robust, and the initial setup, while complex, went smoothly following the provided manuals. The service from the manufacturer’s support team has been a mixed bag. Initial inquiries were answered promptly, but as we moved into more technical troubleshooting for integration, responses became slower. They are knowledgeable when they do respond, but the delay can be frustrating when production timelines are tight. Overall, while the core product seems well-made, the entire experience was marred by significant logistical failures and inconsistent support. The potential is there, but the process to get to a fully operational state was far more stressful and time-consuming than anticipated.

Beyond expectations in every aspect. Beginning with the logistics, the shipment arrived ahead of schedule, which was a fantastic and welcome surprise. The packaging was exceptionally secure, ensuring every component was perfectly intact upon arrival. Regarding quality, the build of the machinery is robust and clearly designed for heavy-duty, continuous operation. The materials used feel premium and durable. As for service, the support team was brilliant from the initial inquiry through to post-delivery. They were responsive, patient with questions, and provided clear, helpful documentation. The installation guidance was thorough. This level of comprehensive care in logistics, product quality, and customer service is truly commendable and makes the entire procurement process seamless and reliable. A highly satisfactory experience from start to finish.

Wanted to share my thoughts on the recent order. The shipping was remarkably fast and well-organized. Everything arrived ahead of schedule, which was a pleasant surprise given the size of the equipment. The packaging was secure and professional, with no signs of damage during transit. Regarding the machine itself, the build quality appears robust and meets the specifications outlined. The materials used feel durable, and the assembly is precise. As for customer service, the communication was clear and helpful throughout the process. My inquiries were answered promptly and thoroughly. Overall, a very satisfactory experience from start to finish. The efficiency of the logistics and the apparent quality of the product are commendable. The support team was also very professional and made the process smooth.

Zippy delivery was a pleasant surprise, with the machine arriving well ahead of schedule. The build quality feels robust and reliable, showing excellent craftsmanship in the materials used. Customer service was highly responsive and helpful throughout the process, addressing all my queries promptly. Overall, a very satisfying experience that I'd recommend to others.

Upon receiving the machine, I was thoroughly impressed by the swift and secure delivery process. The packaging was robust, ensuring no damage during transit, which is a huge relief for such a critical piece of equipment. Ultimately, the quality of the machine appears top-notch, with sturdy construction and precise engineering that promises reliability. Moreover, the customer service team was exceptionally responsive and helpful, addressing all my queries promptly and professionally. Using this machine has streamlined our production, and I highly recommend it for anyone in the disposable footwear industry.