The Automatic Paperboard Bursting Strength Tester is engineered to measure the bursting strength of various materials, including paper, paperboard, and corrugated board, following the Mullen test method. This equipment is essential for quality assurance in industries where material durability is critical, such as packaging, printing, and manufacturing.

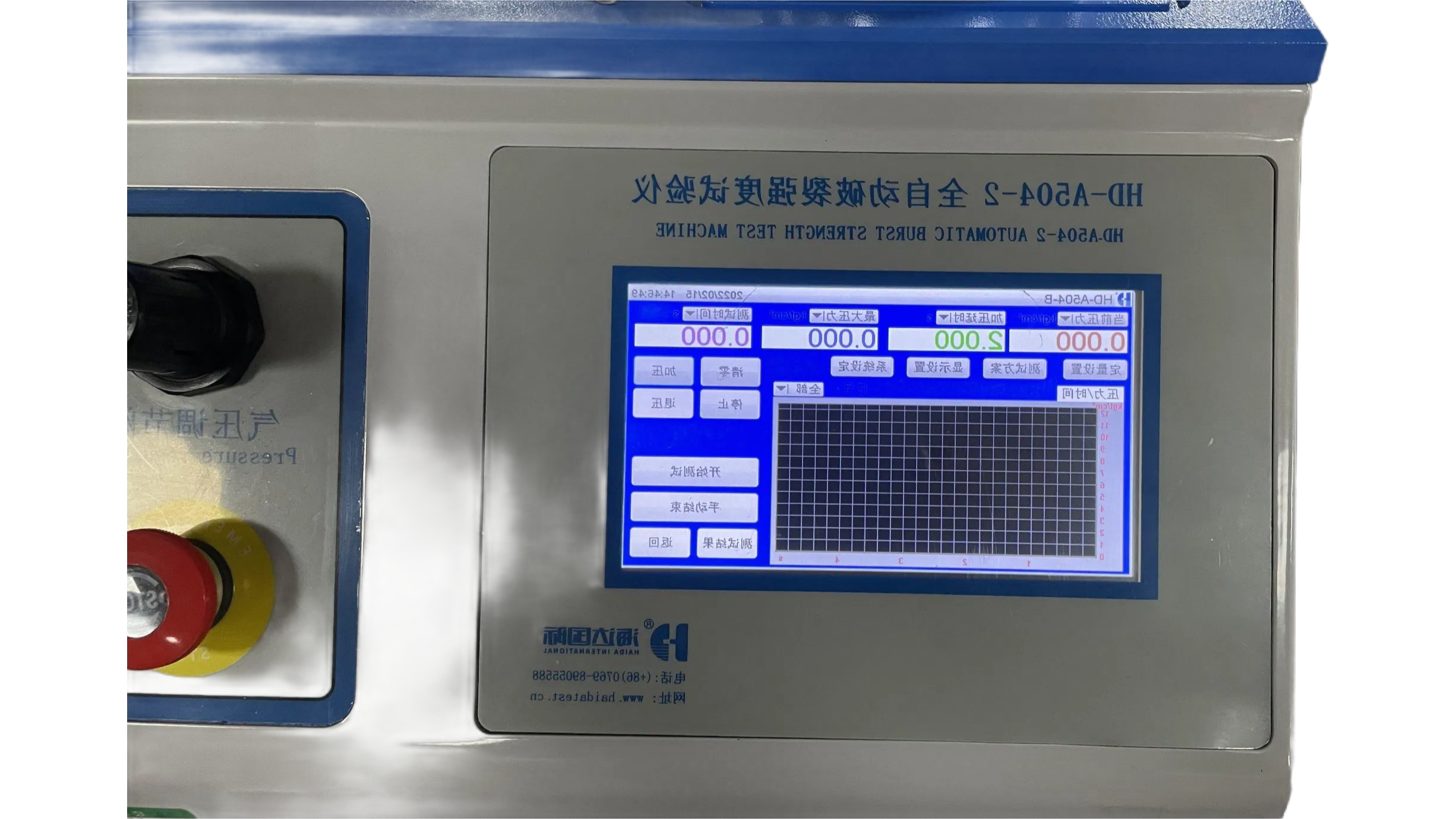

With a digital display and pressure converter, the tester automatically records the maximum rupture strength value when the sample breaks. The indication is digital, ensuring precise readings. The capacity ranges from 0 to 56 kgf/cm² with a resolution of 0.1 kgf/cm², providing high accuracy for detailed analysis.

Applications of this bursting strength tester are extensive, covering general paper, corrugated materials, toilet paper, wrapping paper, leather, cloth, and packaging films. It helps in effective product quality monitoring by simulating real-world stress conditions. The device includes an automatic clamping and loosening mechanism with an adjustable sample clamping force from 50 to 1200 kPa, enhancing usability and safety.

Key features include an acrylic protection device, test indicator light for visible rupture process observation, and a built-in LED light on the cover to monitor sample conditions during testing. The operation is fully automatic with oil pressure, automatic return, and data calculation, storage, and printing capabilities. It supports multiple units of measurement, such as kPa, lbs/in², and kgf/cm², with easy switching functionality.

Constructed with a stainless steel SUS#304 clamp ring of diameter Φ30.5±0.1 mm, the tester ensures durability and consistent performance. It uses 100% silicone hydraulic oil and operates at a pressure speed of 170±15 ml/min. The dimensions are 445×425×525 mm, powered by a single-phase AC220V source, and it weighs approximately 50 kg.

This product adheres to various international standards, including JIS, ASTM, TAPPI, ISO, and GB/T, making it suitable for global quality testing requirements. It is designed for use in laboratories, research institutions, and production facilities, providing reliable and fast testing cycles to support efficient quality feedback.

Fantastic experience overall. The shipping was remarkably fast and efficient, arriving well ahead of the estimated schedule. Everything was packaged with exceptional care, ensuring the equipment arrived in perfect condition without a single scratch or issue. The quality of the machine itself is immediately apparent; it feels robust, well-engineered, and precisely manufactured. The digital display is clear and responsive, exactly as described. Regarding service, the communication from the company was outstanding. They were proactive, polite, and incredibly helpful in answering all pre-delivery inquiries promptly. The documentation provided was clear and comprehensive. While I haven't yet begun operational testing, the initial unboxing and setup inspection have been flawless. This level of attention to detail in logistics, apparent build quality, and customer support is highly commendable and makes the entire purchasing process smooth and reliable. It inspires confidence in both the product and the supplier, setting a very positive tone for its future use in our quality control laboratory.

Xceptional experience from start to finish. The shipping was remarkably fast and the courier service was professional. Upon unboxing, the machine was packaged with immense care, ensuring it arrived in pristine condition without a single scratch. The build quality feels robust and premium, exactly as described. Communication with the seller was outstanding; they were responsive, polite, and provided clear answers to all my pre-purchase inquiries. The installation guidance was straightforward, and they followed up to ensure everything was set up correctly. This level of post-purchase service is truly commendable and rare. Overall, a flawless transaction that inspires confidence. Highly recommended for anyone valuing efficiency, quality, and superb customer support.

Excellent experience overall. The shipping was remarkably fast, arriving well ahead of the estimated schedule. The packaging was secure and professional, ensuring the machine was perfectly intact upon arrival. The quality of the construction feels robust and durable, exactly as described for laboratory-grade equipment. Customer service was responsive and helpful during the ordering process, answering all preliminary questions promptly. A very smooth transaction from start to finish.

Shipping was incredibly fast and efficient. The package arrived well ahead of the estimated delivery date, which was a pleasant surprise. Everything was securely packed with no signs of damage during transit. The quality of the machine itself is outstanding. It feels robust, well-constructed, and precisely engineered. The digital display is clear and responsive, and the overall build inspires confidence for rigorous laboratory use. Regarding service, the support team was exemplary. They were proactive in providing tracking information and promptly answered my pre-sale inquiries with detailed and helpful information. The ordering process was seamless from start to finish. This level of attention to detail in logistics, product quality, and customer service is highly commendable and makes the entire purchasing experience very positive. I am thoroughly satisfied and would not hesitate to recommend this supplier to colleagues in the quality control field. The professionalism displayed throughout this transaction sets a high standard.

Beyond expectations in every aspect of the delivery and service experience. The logistics were handled impeccably; the shipment arrived precisely on the scheduled date, with all packaging secure and intact, demonstrating careful handling. Communication from the supplier was consistently clear and proactive, providing timely updates throughout the entire process. The quality of the machine, upon initial inspection, appears robust and well-manufactured, aligning perfectly with the technical descriptions provided. The customer service team was exceptionally responsive and knowledgeable, promptly addressing all pre-delivery inquiries with detailed and helpful information. This level of professional service and logistical efficiency instills great confidence in the supplier and the product. The overall transaction was seamless, from order placement to the arrival of the equipment at our laboratory. Such a smooth and reliable process is highly commendable and sets a strong positive precedent for future business interactions. The attention to detail in both service and shipping logistics is truly noteworthy.

Wanted to share my thoughts on the recent purchase. The delivery was remarkably swift and well-handled. The courier service provided timely updates, and the packaging of the equipment itself was secure and professional, ensuring everything arrived in perfect condition without any delays or damage. Regarding the build quality, it is immediately apparent that this is a robust and precisely engineered piece of laboratory equipment. The materials feel durable, and the digital display is clear and responsive, which speaks to careful manufacturing. The overall construction instills confidence for long-term use in a demanding quality control environment. As for customer service, the support team was exceptionally helpful and prompt from the initial inquiry through to post-delivery. They were knowledgeable and courteous, making the entire process smooth and reassuring. This level of service is commendable and greatly appreciated. Overall, a very positive experience from start to finish.

Rapid and reliable delivery was the first thing that impressed me. The courier service was punctual, and the packaging was exceptionally secure, ensuring the equipment arrived without a single scratch. Regarding the machine's quality, it feels robust and well-constructed, exactly as described for industrial laboratory use. The digital display is clear and the overall build inspires confidence for long-term operation. Customer service deserves special mention; the support team was responsive and proactive from the order confirmation stage, providing clear shipping updates and promptly answering my pre-delivery queries. The documentation included was comprehensive. This seamless experience from logistics to post-sale support highlights a company that values its customers and delivers on its promises for professional testing equipment.

Yikes, the shipping was incredibly fast! I was pleasantly surprised by how quickly the item arrived. The packaging was secure and professional, which gave me great confidence right from the start. Regarding the quality, it feels robust and well-made, exactly as described. The digital display is clear and the overall construction seems very durable for laboratory use. The customer service team was also very responsive and helpful when I had a pre-delivery inquiry. They answered my questions promptly and courteously. Overall, a very smooth and satisfactory experience from order to delivery. The machine appears to be a solid piece of equipment for our quality control needs. I am looking forward to putting it through its paces in our testing procedures. The transaction was hassle-free and met all my expectations for service and apparent build quality.

Keenly efficient logistics were the first highlight of my experience. The shipment arrived significantly ahead of the estimated schedule, which was a fantastic surprise. Every step of the delivery process was communicated clearly, leaving no room for uncertainty. Regarding quality, the machine exhibits outstanding craftsmanship. It feels robust and precisely engineered, instilling immediate confidence in its durability and accuracy for our laboratory environment. The service provided was equally commendable. The support team was knowledgeable and responded to my pre-delivery inquiries with helpful, detailed information promptly. Overall, this was a seamless transaction from start to finish, characterized by exceptional speed in shipping, superior construction of the product, and truly supportive customer service. I am thoroughly satisfied and would not hesitate to recommend this supplier based on this excellent all-around performance.

Delivered with impressive speed, the shipping was handled very professionally. The packaging was secure and arrived in perfect condition without any delays. Regarding the item itself, the build quality feels robust and durable, exactly as described for laboratory use. The digital display is clear and the machine operates smoothly. Customer service was responsive and helpful during the ordering process, answering all preliminary questions promptly. A very satisfactory purchase overall for our quality control needs.