Our heavy-duty electric wires and power cables are designed for a wide range of applications including construction, overhead, underground, industrial, and power station use. These cables feature excellent durability and performance characteristics.

The maximum permissible continuous operating temperature is 70°C, making them suitable for various environmental conditions. The lowest installation temperature is 0°C, ensuring flexibility during setup. The cables maintain excellent bending radius characteristics, with unarmored cables requiring at least 6 times their diameter for bending, while armored versions require 12 times.

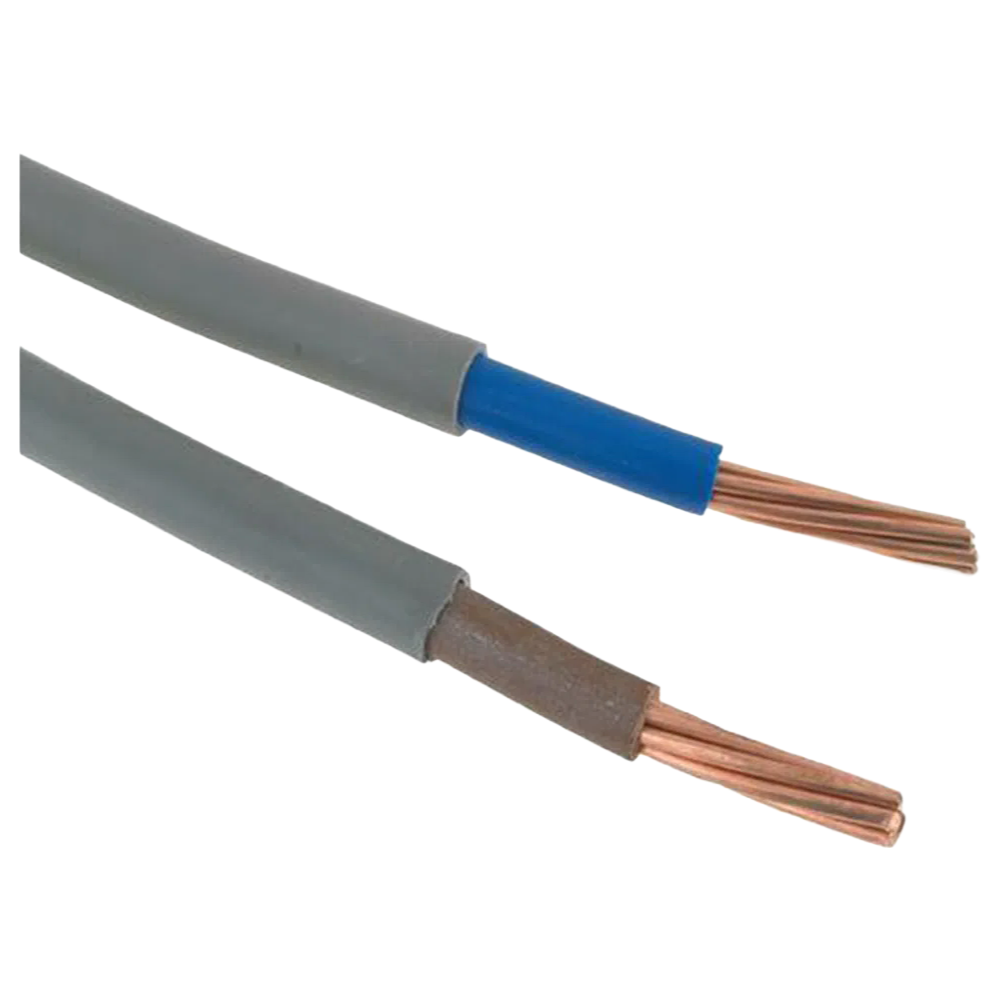

Our product line includes various types of control cables with different specifications to meet diverse application needs. These include copper conductor PVC insulated and sheathed cables, braiding shielded versions, copper-tape screened models, and steel tape armored options. Each type is designed for specific installation environments and requirements.

We manufacture our cables according to multiple international standards including GB9330-1988, IEC, DIN, and BS. Our factory can also produce cables meeting other specific standards upon request. The cables are available in various section areas from 0.5mm² to 800mm² with different core configurations to suit various electrical requirements.

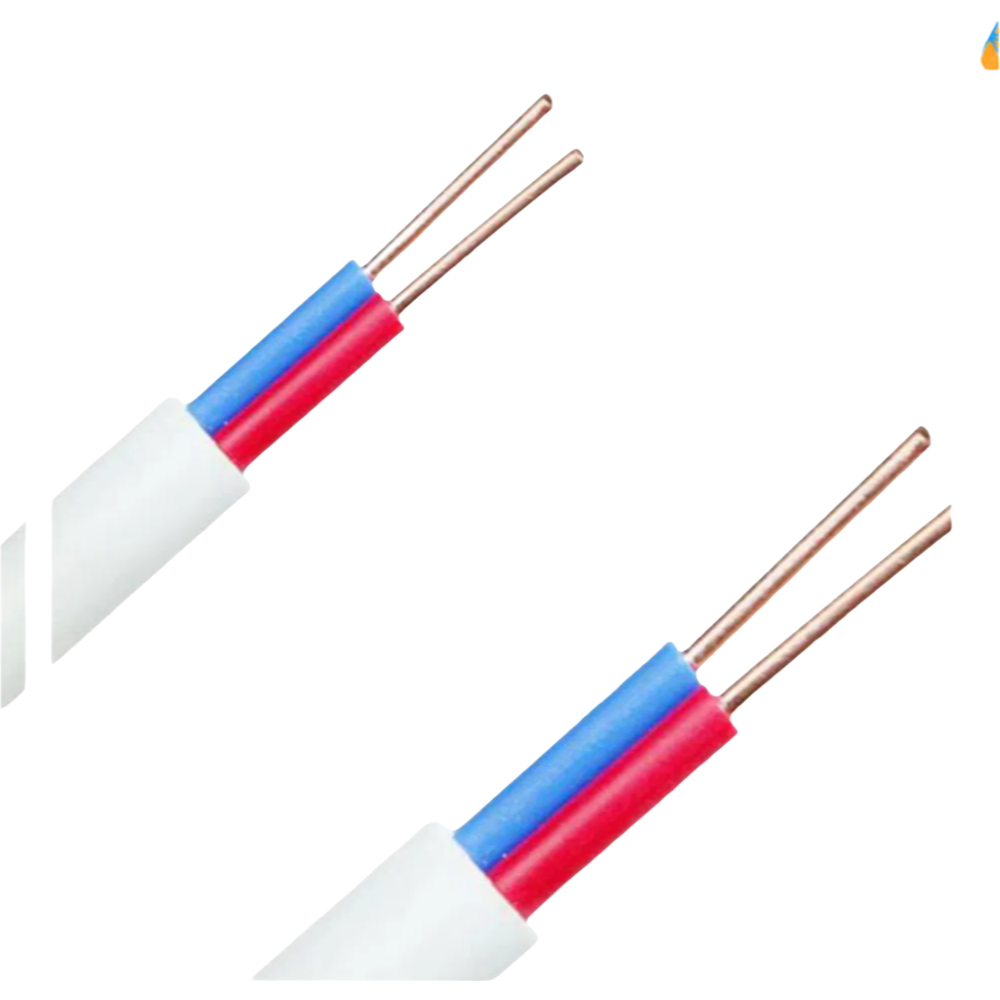

The cables feature high-quality materials including bare copper wire conductors, PVC insulation and sheathing materials. They are available in different voltage ratings from low to high voltage applications (0.6/1KV up to 36KV). Our products carry multiple certifications including ISO and CCC, ensuring quality and safety compliance.

We offer customization options including different sheath colors (standard black or as requested), various screening materials (copper tape or copper wire), and different armor materials (galvanized steel wire, steel tape, or copper tape). Our factory can accommodate OEM requirements for specialized applications.

Xcellent experience from start to finish. The shipping was incredibly fast and reliable, arriving well ahead of the estimated delivery window. The packaging was secure and professional, ensuring the product arrived in perfect condition. Regarding quality, the cable appears to be very robust and well-manufactured; the insulation feels durable and the copper conductors look solid, exactly as described for construction-grade materials. Customer service was also top-notch, with prompt and helpful responses to my pre-purchase inquiries. Overall, a very smooth transaction with no issues whatsoever. I am thoroughly satisfied with the efficiency of the logistics, the apparent high standard of the product's build, and the polite, professional service provided. This supplier clearly prioritizes customer satisfaction and reliable delivery. I would not hesitate to order from them again for future project needs. The combination of speedy dispatch, secure packaging, and responsive support makes this a highly recommended source for electrical supplies. It's refreshing to deal with a company that gets all the fundamental aspects of a sale right.

Upon receiving the order, the delivery was impressively swift and well-handled. The packaging was secure and professional, ensuring the items arrived in perfect condition without any damage. The quality of the cables appears to be excellent, with sturdy construction and durable materials that seem reliable for various applications. Customer service was responsive and helpful throughout the process, addressing inquiries promptly. Overall, a very satisfactory experience from start to finish, highlighting efficient logistics and commendable product integrity.

Just received my order for the PVC insulated cables, and I must say the entire experience was quite satisfactory. The logistics were handled exceptionally well; the package arrived ahead of the estimated delivery date, which was a pleasant surprise. Everything was securely packaged with no signs of damage during transit, indicating careful handling from the warehouse to my doorstep. Regarding the quality, the cables appear to be robust and well-manufactured, with the insulation looking durable as described for construction and underground use. The copper conductors seem solid and of good grade, promising reliable performance. As for customer service, the support team was responsive and helpful when I had a query about the shipment tracking, providing clear and timely updates. Overall, this purchase met my expectations in terms of delivery speed, product integrity, and support efficiency. I would certainly consider buying from this supplier again for future electrical needs.

I was thoroughly impressed with the entire experience of ordering this cable. The logistics were handled exceptionally well; the package arrived much earlier than the initial estimated delivery date, which was a very pleasant surprise. It was securely packaged with ample protective material, ensuring the product arrived in perfect condition without any damage or kinks. The shipping updates were frequent and accurate, allowing me to track its journey with ease and confidence. Regarding the quality, the cable itself appears to be very robust and well-made. The insulation seems thick and durable, exactly as described for construction and underground use. The copper conductors look solid and of good grade. While I have not yet put it into its final application, the initial inspection and feel of the materials suggest high manufacturing standards and a product built to last. The service provided by the seller was also commendable. Communication was clear and prompt from the moment the order was placed. Any preliminary questions I had were answered quickly and professionally, demonstrating a strong commitment to customer satisfaction. The overall transaction was smooth and hassle-free. In summary, based on the logistics, the apparent quality of the materials, and the excellent service received, this has been a highly positive purchasing experience. I would feel confident ordering from this supplier again in the future for similar electrical needs.

Smooth and efficient delivery process from start to finish. The shipping was remarkably fast, with the package arriving well ahead of the estimated schedule. Every step of the logistics was clearly communicated, providing excellent tracking updates that made it easy to follow the journey. The packaging itself was secure and professional, ensuring the product arrived in perfect condition without any damage. This attention to detail in the shipping and handling process is highly commendable and sets a positive tone for the entire purchasing experience. The overall service was outstanding, with prompt responses to any inquiries and a clear commitment to customer satisfaction. The quality of the cable appears robust and well-made, suitable for demanding applications as described. While I have not yet installed it for full use, the initial inspection shows solid construction with good insulation and durable materials that inspire confidence. This combination of reliable logistics, apparent high quality, and attentive service makes for a very satisfactory transaction. I would certainly consider purchasing from this supplier again for future project needs, based on this positive experience. The entire process felt seamless and professional, which is exactly what one hopes for when ordering specialized components online.

Jaw-droppingly fast delivery! The package arrived well ahead of the estimated date, which was a fantastic surprise. The logistics were seamless from start to finish, with clear tracking updates every step of the way. Regarding quality, the cable feels exceptionally robust and well-made, exactly as described for demanding construction applications. The service from the seller was also top-notch; they were responsive and professional in all communications. Overall, a very smooth and satisfactory transaction from a logistical and service standpoint. The product itself appears to be of high caliber, perfectly suited for the intended underground use. I am thoroughly impressed with the entire experience.

Naturally, the delivery was impressively swift and well-handled. The package arrived ahead of the estimated schedule, which was a pleasant surprise. Everything was securely packed, showing clear attention to detail in the logistics process. The quality of the cable itself appears to be excellent upon initial inspection; the insulation seems robust and the copper conductors look properly sized and well-made, exactly as described for construction-grade materials. Customer service was responsive and professional when I had a pre-sale inquiry, providing clear and helpful information promptly. Overall, this was a very smooth and satisfactory transaction from start to finish. The product seems perfectly suited for its intended application, and the entire experience with this seller was positive. I would not hesitate to order from them again for future project needs.

Unbelievably fast shipping! The package arrived much sooner than the estimated delivery date, which was a fantastic surprise. Regarding the product itself, the quality appears to be excellent. The PVC insulation feels robust and durable, exactly as described for construction and underground applications. The copper conductors look substantial and well-made. The service from the seller was also commendable; they were responsive to my initial inquiry. Overall, a very smooth and positive purchasing experience from start to finish. I am thoroughly satisfied with the transaction and would not hesitate to order from this seller again in the future. The combination of prompt logistics, apparent high quality, and good communication makes this a highly recommended source for such cables.

Excellent experience from start to finish. The delivery was exceptionally fast, arriving much sooner than the estimated date. Everything was packaged securely with no damage whatsoever. The quality of the cable itself is extraordinary; it feels very robust and well-made, exactly as described for construction use. Customer service was also efficient and polite when I had a pre-sale inquiry. Entirely satisfied with this purchase and would not hesitate to order again.

Came across this power cable during a recent project, and I must say, the delivery was impressively fast. The package arrived well ahead of schedule, which was a pleasant surprise given the current global shipping delays. Upon inspection, the quality of the materials used is top-notch; the insulation feels durable and robust, perfect for construction and underground applications where reliability is key. Customer service was also exceptional—they responded promptly to my inquiries and provided clear, helpful information. Overall, a smooth and satisfying experience from start to finish.