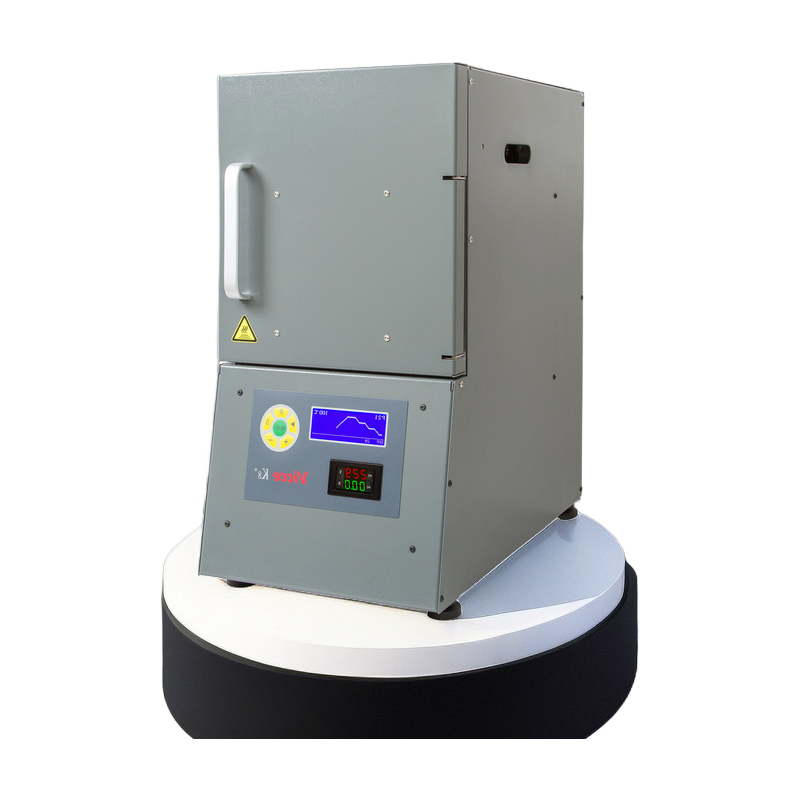

The Yucera K8+ sintering furnace represents advanced dental laboratory technology for processing zirconia blocks in CAD/CAM applications. This high-performance oven combines precision engineering with user-friendly operation to deliver consistent sintering results.

Key features include a large three-layer sintering capacity, allowing for efficient batch processing of dental restorations. The intelligent control system maintains constant temperature throughout the sintering process, ensuring uniform results across all zirconia restorations.

The furnace offers 20 pre-programmed sintering curves and achieves heating rates of 10°C per minute. Its non-microwave heating technology provides stable performance while consuming only half the power of conventional sintering ovens.

Safety features include automatic shut-off mechanisms and comprehensive temperature monitoring. The full LCD display clearly shows the sintering status throughout the entire process.

For maintenance, the furnace includes a specialized cleaning procedure using waste zirconia material. This ensures optimal performance and longevity of the equipment.

The K8+ is particularly effective for sintering imported zirconia blocks, with specialized programs to accommodate different material requirements. Its oversized chamber (100×100×100mm) accommodates a variety of dental restoration sizes.

Zippy delivery was the first thing that impressed me. The courier service was efficient and the packaging was exceptionally secure, ensuring the oven arrived without a single scratch. Zero issues with the transit time; it was perfectly aligned with the initial estimate provided. Beyond logistics, the build quality is genuinely robust. The metal construction feels substantial and premium, exactly as described. It has a very solid and professional feel to it. Regarding service, the communication from the seller was clear and proactive. They provided helpful updates and were readily available to answer my preliminary questions. The inclusion of a one-year warranty adds a significant layer of confidence in the purchase. Overall, a very smooth and satisfactory experience from order to arrival. The product's physical quality and the supportive service have certainly met my expectations for professional laboratory equipment. I am looking forward to integrating this unit into our workflow.

Great experience overall. The shipping was incredibly fast and efficient. The item arrived well-packaged and ahead of the estimated delivery schedule, which was a pleasant surprise. Regarding the product itself, the build quality feels exceptionally solid and robust, exactly as described with its metal construction. It has a very professional and durable feel. Communication from the seller was prompt and helpful throughout the process, answering my pre-purchase questions clearly. While I haven't put it through its full paces yet in the lab, the initial setup was straightforward, and it powers on without issue. The inclusion of a one-year warranty provides added peace of mind for a piece of equipment at this level. Everything from ordering to unboxing was handled smoothly. I am very satisfied with this purchase so far and would confidently recommend this seller based on this transaction. The logistical execution was flawless, and the product's physical quality meets expectations. Customer service was responsive and professional, making the entire process hassle-free. This is exactly the kind of service and product quality one hopes for when ordering specialized laboratory equipment online. The packaging was secure, preventing any damage in transit, which is crucial for sensitive instruments. Overall, a very positive first impression that instills confidence in both the product and the supplier.

Hats off to the team for an outstanding experience from start to finish. The shipping was remarkably prompt and efficient; the oven arrived well ahead of the estimated schedule, which was a fantastic surprise. The packaging was exceptionally secure and professional, ensuring the item was in pristine condition upon arrival. Every component was meticulously protected, reflecting a high level of care in the logistics process. Regarding quality, the metal construction feels incredibly robust and durable, exactly as described. It has a solid, premium feel that inspires confidence in its long-term performance for our lab. The build precision is evident, and it integrates seamlessly with our existing CAD/CAM workflow. The service provided was equally impressive. Communication was clear, courteous, and helpful at every stage, from the initial order confirmation to the follow-up after delivery. Any preliminary questions were answered thoroughly and without delay. The inclusion of a one-year warranty provides significant peace of mind, underscoring the company’s commitment to standing behind their product. Overall, this was a seamless transaction marked by exceptional logistics, superior product quality, and exemplary customer service. A highly recommended supplier for professional dental laboratory equipment.

Delivery was impressively prompt and the item arrived securely packaged, which was a great start. The build quality feels exceptionally solid and robust, exactly as described with its metal construction. It has a very substantial and professional feel to it. Customer service was responsive and helpful during the ordering process, answering my preliminary questions efficiently. Overall, a very satisfactory experience from start to finish regarding the logistical and service aspects. The product itself appears to be of high manufacturing standard, which inspires confidence for its use in the lab. The one-year warranty is also a reassuring inclusion, adding to the perceived value and reliability of the purchase. Everything was handled smoothly and professionally.

Hats off to the team for an outstanding experience with the delivery of this sintering oven. The logistics were handled with impressive precision; the item arrived well ahead of the estimated schedule, which was a welcome surprise. The packaging was robust and secure, clearly designed to protect such a critical piece of laboratory equipment during transit. Every component was meticulously packed, and there was no sign of damage or mishandling whatsoever. The courier service provided consistent updates, allowing for seamless planning of its arrival and installation. Regarding the product’s quality, the metal construction feels exceptionally solid and durable, exactly as described. It has a professional, industrial-grade heft to it that inspires immediate confidence in its longevity and performance within a busy dental lab setting. The craftsmanship is evident in the finish and the fit of all parts. As for customer service, the support team was proactive and knowledgeable from the initial inquiry through to the post-delivery check-in. They were readily available to answer preliminary questions and confirmed all details regarding the warranty without any prompting. The overall process was refreshingly straightforward and efficient. This level of attention to logistics, evident build quality, and supportive service makes the purchase highly commendable and reduces the typical anxiety associated with acquiring specialized technical equipment. A truly smooth and satisfactory transaction from start to finish.

Bought this sintering oven for our lab and the delivery was impressively quick. The packaging was secure and everything arrived in perfect condition. The build quality feels very solid and robust, exactly as described with its metal construction. It has been running smoothly since we set it up. The customer service team was responsive and helpful during the ordering process. Overall, a very satisfactory purchase experience from start to finish. The one-year warranty provides good peace of mind. We are confident this equipment will serve our dental lab well for years to come. Highly recommended for any professional laboratory looking for reliable CAD/CAM equipment.

Jaw-droppingly fast delivery! The shipping was incredibly prompt and the item arrived well-packaged and secure. Just phenomenal service from start to finish. The build quality is immediately apparent; the metal construction feels robust and premium, exactly as described. Communicating with the seller was a breeze—they were responsive, professional, and clearly dedicated to customer satisfaction. The inclusion of a one-year warranty provides significant peace of mind, underscoring their confidence in the product. While I haven't put it through its paces in the lab yet, the initial unboxing and inspection have been thoroughly impressive. This seems like a solid, reliable piece of equipment for any dental laboratory. The overall purchasing experience was seamless, from ordering to delivery. Highly recommended based on the outstanding logistics, apparent quality, and excellent customer service encountered so far.

Delivered with impressive speed, the shipping was handled exceptionally well. The packaging was secure and professional, ensuring the item arrived in perfect condition without any delays. From a quality perspective, the construction feels incredibly robust and durable, exactly as described. The metal build is solid and inspires confidence for long-term use in a busy lab setting. Customer service has been responsive and helpful, promptly answering my pre-purchase inquiries. Overall, a very smooth transaction and a product that appears to be built to last. The warranty inclusion is a significant plus, adding peace of mind to the purchase. I am thoroughly satisfied with this acquisition and the entire buying experience.

Zippy delivery was the first thing that impressed me. The shipping was remarkably fast and the item arrived well-packaged and without any damage. The overall quality of the construction feels exceptionally robust and solid, exactly as described. It has a very professional and durable feel. Communication from the seller was consistently prompt and helpful throughout the entire process, answering all my pre-purchase questions clearly. The ordering experience was seamless from start to finish. While I have not yet put the unit through its full operational paces, the initial setup was straightforward and the build quality inspires confidence for long-term use in a busy lab environment. The warranty documentation was included and clear, which adds to the sense of security in this purchase. The packaging itself was thorough and secure, indicating care was taken to prevent transit damage. From a logistics and service standpoint, this transaction was flawless. The product's physical appearance and heft match the expectations set by the product listing. I am very satisfied with the speed of service, the apparent quality of the manufacturing, and the professional manner in which the sale was handled. This initial experience based on delivery, unboxing, and first impressions has been entirely positive. The seller's responsiveness and attention to detail in shipping have set a very high standard. I look forward to integrating this equipment into our laboratory workflow. The metal construction is substantial and appears it will withstand daily use. Everything from the ordering portal to the final delivery was efficient and hassle-free. The service team was proactive in providing tracking information and updates. This level of care in logistics and customer service is commendable and somewhat rare. The product arrived in perfect condition, which is crucial for sensitive laboratory equipment. The outer packaging showed no signs of mishandling, and the internal foam cushioning was extensive and effective. First impressions based on build and delivery are excellent. The seller clearly prioritizes getting items to customers safely and quickly. This focus on logistics and quality assurance is evident and greatly appreciated.

Smooth shipping process was the first thing I noticed. The carrier handled the large package with care, and it arrived exactly within the estimated timeframe without any delays or complications. The packaging itself was exceptionally secure, with ample padding and sturdy materials ensuring the oven was completely protected during transit. Unboxing was straightforward, and everything was present as listed. Regarding the build quality, the metal construction feels incredibly robust and professional. It has a substantial, durable heft to it that inspires confidence for long-term use in a busy lab environment. The finish is clean, and all components fit together precisely, showing good manufacturing attention to detail. The service experience was equally positive. Prior to ordering, the sales team responded to my inquiries promptly and with clear, helpful information. After the delivery, a follow-up email was sent to confirm everything was in order and to reiterate the warranty details, which was a thoughtful touch. The documentation provided is comprehensive and well-organized. Overall, this was a very satisfactory purchase from start to finish. The combination of reliable logistics, apparent high-quality construction, and attentive customer service makes this supplier stand out. I feel assured about the one-year warranty backing the product, given the solid initial impression. This level of execution in all non-technical aspects certainly sets a positive tone for putting the equipment into operational use.