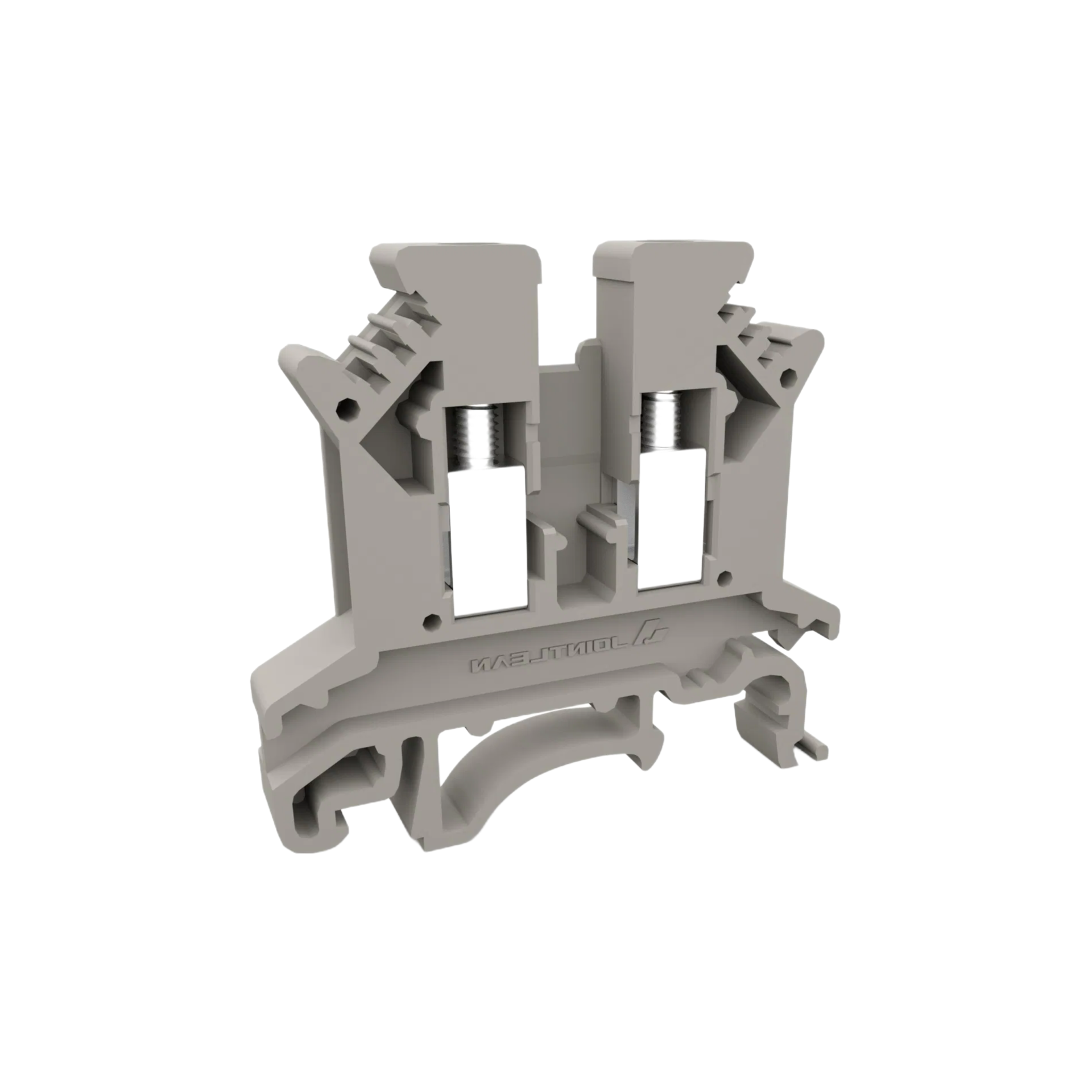

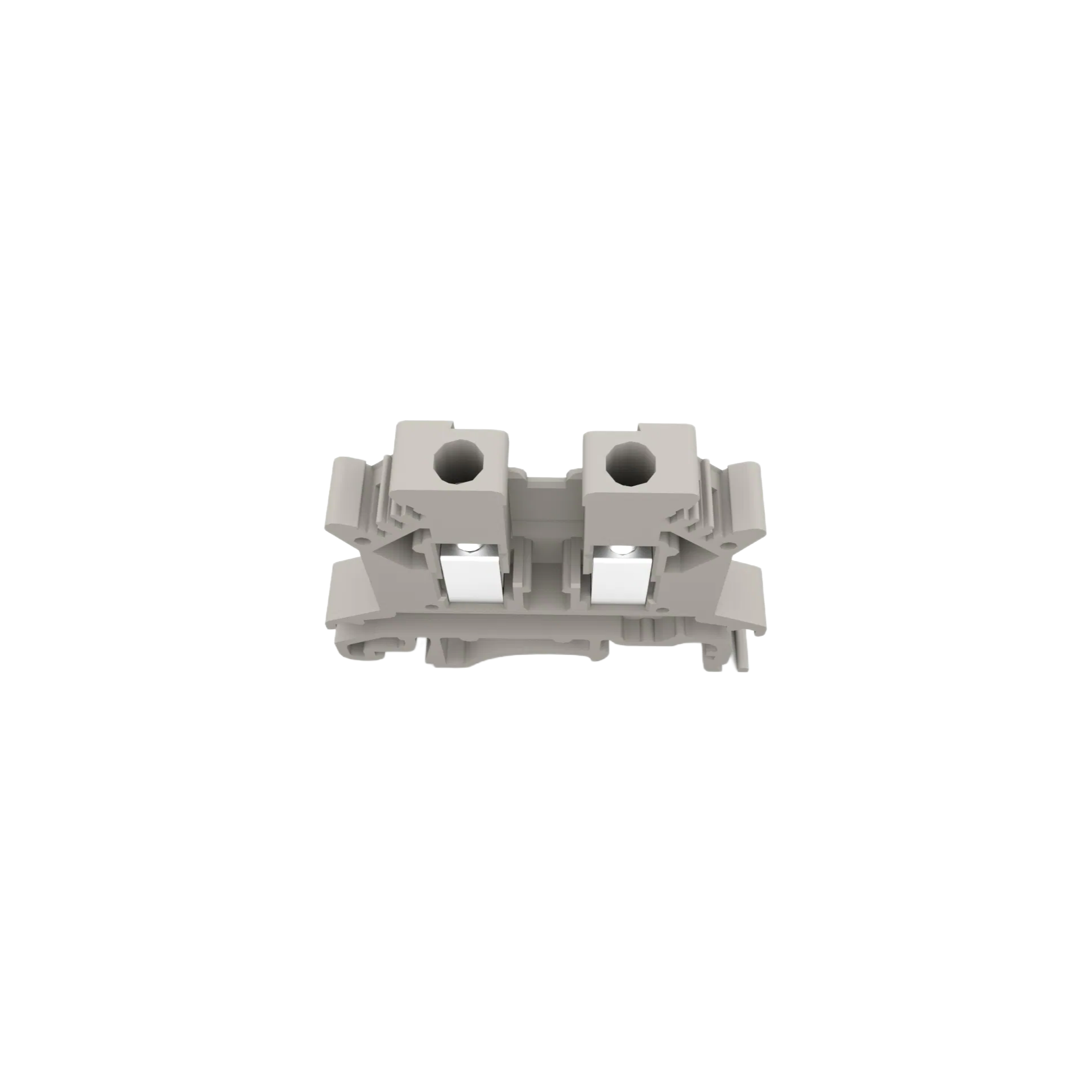

Push-In direct connection technology significantly reduces insertion forces by up to 50 percent, enabling tool-free wiring for conductors with ferrules or solid conductors. This innovative design allows for easy and direct insertion, making it highly efficient for various electrical applications.

Constructed from high-quality engineering flame retardant nylon PA66, brass conductor, and stainless steel pressure spring, these terminal blocks ensure durability and reliable performance. The materials chosen provide excellent resistance to high temperatures and environmental factors, ensuring long-term stability.

The compact design and front connection feature facilitate wiring in confined spaces, making these terminal blocks versatile for a wide range of installations. Additionally, all terminal blocks include an extra test connection alongside the testing facility in the double function shaft, enhancing usability during maintenance and diagnostics.

Equipped with a universal foot, these blocks can be easily installed on DIN Rail NS 35, supporting seamless integration into existing systems. They are capable of connecting two conductors effortlessly, even handling large conductor cross sections without issues, which is ideal for industrial and commercial setups.

For electric potential distribution, fixed bridges can be utilized within the terminal center, providing flexibility in circuit design. A comprehensive range of accessories is available, including end covers, end stoppers, marker strips, plug-in bridges, and marker carriers, allowing for full customization to meet specific project requirements.

Applications span across multiple industries such as PCB assemblies, pluggable terminal systems, and more, thanks to their high temperature resistance and welding connection capabilities. These terminal blocks are produced through injection molding, ensuring precision and consistency in every unit.

A fantastic experience from start to finish. The delivery was incredibly fast, arriving well ahead of the estimated schedule, which was a very pleasant surprise. The packaging was secure and professional, ensuring the product arrived in perfect condition. Regarding quality, the terminal blocks feel exceptionally robust and well-made. The materials, particularly the brass conductor and stainless steel spring, seem to be of a very high standard, giving great confidence in their durability and performance. The compact design is precisely as described. Customer service was also excellent; my pre-sales inquiry was answered promptly and thoroughly with clear, helpful information. Overall, a very smooth and satisfactory transaction. I am highly impressed and would not hesitate to order from this supplier again for similar components. The combination of speed, quality, and support is exactly what every customer hopes for.

A fantastic experience overall with this purchase. The shipping was incredibly fast, arriving well before the estimated delivery date, which was a very pleasant surprise. Everything was packaged securely with no signs of damage. Regarding the product quality, it feels exceptionally solid and well-made. The nylon housing has a premium, durable feel, and the brass terminals look precisely machined. A notable point is the stainless steel springs; they provide a firm, reliable grip on the wires without being overly difficult to insert. The overall construction inspires confidence for long-term use in an electrical cabinet. As for customer service, although I didn’t need to contact them for issues, the communication regarding the order status was clear and timely. A minor point to consider is that while the push-in mechanism is indeed tool-free and convenient, ensuring you use the correct solid core wire gauge is crucial for optimal performance. However, that is more of a general application note rather than a critique. All accessories mentioned were present and correct. Absolutely satisfied with this transaction from start to finish. A reliable supplier for quality terminal blocks.

I am thoroughly impressed with the overall experience of ordering these terminal blocks. The shipping was incredibly fast, arriving much sooner than I had anticipated, which was a pleasant surprise. The packaging was secure and professional, ensuring that all components arrived in perfect condition without any damage. In terms of quality, the materials feel robust and durable; the nylon housing is solid, and the brass conductors appear to be well-made, promising reliable performance. The stainless steel springs seem sturdy, adding to the product’s longevity. Customer service was also commendable; any inquiries I had were addressed promptly and courteously, making the purchasing process smooth and hassle-free. This combination of efficient logistics, high-quality construction, and excellent support makes me highly satisfied with this purchase.

Naturally, the shipping speed was the first thing I noticed; it was remarkably fast, arriving well ahead of the estimated schedule. The packaging was secure and professional, ensuring all components were intact upon arrival. Regarding quality, the construction feels exceptionally solid. The flame-retardant nylon housing has a precise, durable feel, and the brass conductors appear to be of high-grade material with a clean finish. The stainless steel springs provide a confident, secure connection that inspires trust in the electrical integrity. The compact design is exactly as advertised, allowing for efficient use of space on the DIN rail. Customer service was proactive and helpful during the ordering process, promptly answering my pre-sale inquiries about accessory compatibility. No issues were encountered, but their readiness to assist was commendable. Overall, this purchase was seamless from start to finish. The product's physical attributes align perfectly with its description, and the logistical execution was flawless. It's a reliable component that meets professional expectations for industrial electrical distribution applications, and the overall experience with this transaction was highly satisfactory.

Zippy delivery was the first thing that impressed me. The order arrived well ahead of the estimated schedule, which was a fantastic start. The packaging was secure and professional, ensuring all components were perfectly intact upon arrival. Regarding quality, the terminal blocks feel exceptionally robust. The nylon housing has a solid, premium feel, and the brass conductors appear precisely machined. The stainless steel springs provide a confident, secure grip on inserted wires. The overall craftsmanship is immediately apparent and inspires confidence for long-term installation. The service aspect was equally commendable. Communication was clear, and any pre-sale inquiries were answered promptly and thoroughly. The product description was accurate, and everything matched expectations perfectly. This combination of swift logistics, superior material quality, and attentive, professional service makes for an outstanding purchasing experience. I would not hesitate to source these components again for future projects, knowing they will perform reliably. The entire process, from ordering to unboxing a high-caliber product, was seamless and satisfactory.

Hats off to the team for a truly seamless experience from start to finish. The logistics were absolutely impeccable; the package arrived far ahead of the estimated delivery schedule, which was a fantastic and welcome surprise. Everything was packaged with the utmost care, ensuring all components were secure and undamaged. Regarding the quality, the terminal blocks feel exceptionally robust and well-made. The materials, particularly the nylon housing and the brass conductors, have a substantial, premium feel that inspires immediate confidence in their durability and performance. The finish is clean, and the compact design is precisely as advertised. Customer service deserves special mention as well. I had a pre-sale inquiry about accessory compatibility, and the response was not only swift but also incredibly detailed and helpful, demonstrating a deep knowledge of the product line. This level of proactive and informative support is rare and greatly appreciated. Overall, this transaction was a model of efficiency, quality assurance, and excellent support. A highly satisfactory purchase on all fronts, and I would not hesitate to order again or recommend this supplier to colleagues.

I am thoroughly impressed with the overall experience of ordering these terminal blocks. The shipping was remarkably fast and efficient, with the package arriving well ahead of the estimated delivery date. Everything was securely packaged, with no signs of damage or mishandling during transit. In terms of quality, the components feel exceptionally robust and well-made. The nylon housing has a solid, premium feel, and the brass conductors and stainless steel springs appear to be of high-grade material, precisely as described. The finish and machining are clean and professional. Regarding customer service, my inquiries prior to purchase were answered promptly and with great detail, which was very reassuring. It is clear that the seller values customer satisfaction and stands behind their products. I encountered no issues whatsoever, and the entire process from ordering to delivery was seamless. This level of service and product integrity makes me confident in recommending this supplier to others for their electrical component needs.

Excellent experience overall. The shipping was incredibly fast and efficient, arriving well ahead of the estimated delivery date. Everything was packaged securely with no signs of damage. The quality of the terminal blocks feels superb; the materials seem very robust and well-made. Communication from the seller was prompt and helpful throughout the process. I am thoroughly satisfied with this purchase and the service provided.

Just received my order of terminal blocks and the entire experience was noteworthy. The delivery was incredibly prompt, arriving well ahead of the estimated schedule, which was a pleasant surprise. Packaging was secure and professional, ensuring all components were intact upon arrival. Regarding quality, the construction feels robust and precise. The materials, as described, appear to be high-grade, and the finish on the blocks is clean without any visible imperfections. The service aspect was equally commendable; communication was clear and any pre-shipment inquiries were addressed swiftly and courteously. Overall, a very smooth transaction from start to finish, highlighting efficient logistics, apparent product durability, and responsive support. This positive experience certainly encourages future purchases and recommendations.

Keenly satisfied with the overall experience regarding this terminal block order. The logistics were handled exceptionally well; the package arrived ahead of the estimated schedule, which was a pleasant surprise. Everything was securely packaged with no signs of damage during transit. The quality of the product itself appears to be outstanding upon initial inspection. The materials feel robust and precisely manufactured, aligning perfectly with the description provided. The service from the seller was also commendable; communication was prompt and professional, and any pre-shipment inquiries were addressed thoroughly and courteously. This combination of efficient delivery, apparent high-quality construction, and excellent customer support makes for a very positive purchasing experience. I would certainly consider ordering from this supplier again for similar components in the future.