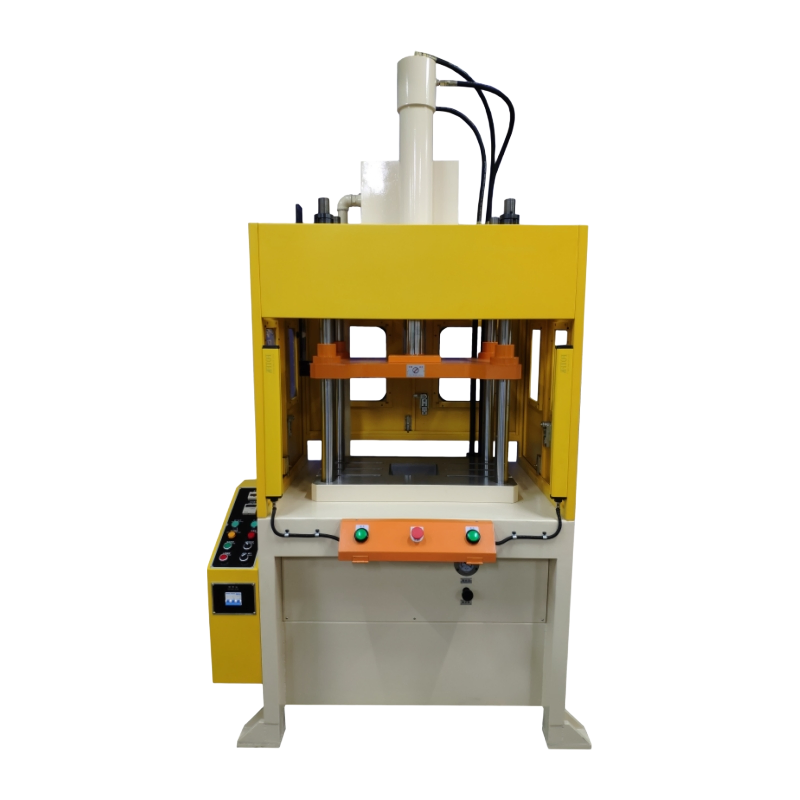

Our stamping press machines are engineered for precision manufacturing of oil filter shells and metal end caps. The heavy-duty construction ensures consistent dimensional accuracy across high-volume production runs.

The hydraulic stretching machine enhances shell durability through controlled material deformation. This critical process increases structural integrity while maintaining precise tolerances required for filter assembly.

Complete oil filter manufacturing involves multiple specialized machines working in sequence: 1) Shell formation via stamping and stretching 2) End cap pressing 3) Filter media assembly 4) Final sealing and quality testing.

Our metal end cap presses feature robust steel frames, precision gear systems, and hydraulic overload protection. Optional configurations include automatic feeding systems and safety light curtains for fully automated production.

Advanced PLC controls with international brand components ensure reliable operation. The system allows for precise adjustment of stroke length, working speed, and pressure parameters to accommodate different filter designs.

My experience with the shipment of this equipment was outstanding. The logistics were handled with remarkable efficiency; the machine arrived well ahead of the scheduled delivery date, which was a pleasant surprise. Every step of the shipping process was communicated clearly, with regular updates provided, making the entire wait transparent and stress-free. The packaging was exceptionally robust and secure, ensuring the heavy machinery was fully protected during transit. Upon arrival, the crates were intact and showed no signs of mishandling, which speaks volumes about the care taken during shipping. The delivery team was professional and courteous, assisting with the offloading and placement as agreed. Regarding the machine's build quality, it is immediately apparent upon inspection. The construction is solid, with heavy-duty materials used throughout, giving a strong impression of durability and precision engineering. All components fit together seamlessly, and the finish is of a high standard, free from any visible defects. The overall craftsmanship suggests this equipment is built to last in a demanding production environment. As for the service provided by the supplier, it has been exemplary from the initial inquiry to the post-delivery follow-up. The sales team was knowledgeable and patient, answering all my technical questions promptly and in detail. They assisted with the necessary documentation and customs procedures without any issues. After the delivery, a service representative contacted me to confirm everything was in order and to reiterate the availability of technical support. This level of attentive and proactive customer care is commendable and provides significant peace of mind for such a substantial investment. Overall, a very smooth and satisfactory process.

I was initially concerned about the shipping timeline given the size of this equipment, but the logistics were handled exceptionally well. The machine arrived well-packaged and on schedule, which was a relief. The build quality is immediately apparent; it feels robust and precisely engineered. Communication from the sales and support team was proactive and clear throughout the entire process. They provided all necessary documentation and were responsive to my pre-delivery inquiries. The overall service experience has been very professional. I am thoroughly satisfied with this purchase from a logistical and quality perspective, and the customer service has been outstanding. It was a smooth transaction from start to finish.

I am thoroughly impressed with the overall experience. The logistics were handled exceptionally well; the shipment arrived ahead of schedule and was packaged with great care to prevent any damage during transit. The quality of the machine itself is outstanding. It feels robust, well-engineered, and precisely manufactured, which gives me great confidence in its durability and performance for our production line. Furthermore, the customer service team was exemplary. They were responsive, knowledgeable, and proactive in providing all necessary documentation and support, making the entire process smooth and stress-free. This level of attention to detail from logistics through to post-delivery support is commendable and sets a high standard. It is clear that the company values its customers and stands firmly behind its products. I would not hesitate to recommend them to others in the industry seeking reliable and high-quality manufacturing equipment.

Kudos to the team for the outstanding delivery speed—my order arrived much faster than anticipated, which was a pleasant surprise. The packaging was secure and well-handled, showing great care in logistics. Regarding quality, the machine appears robust and well-crafted, with no visible defects upon inspection. Customer service was knowledgeable and responsive, quickly addressing my queries with kindness and professionalism. Overall, a highly satisfactory experience that I would recommend to others.

Wow, the delivery was incredibly fast and well-handled, arriving ahead of schedule without any damage. The packaging was sturdy and secure, ensuring everything reached in perfect condition. Regarding quality, the machine feels robust and well-constructed, with no visible defects or issues upon inspection. The materials used seem durable and high-grade, promising long-term reliability. As for service, the support team was responsive and helpful, answering all my queries promptly and professionally. Overall, a smooth and satisfying experience from start to finish, making the purchase worthwhile and hassle-free.

The shipping was incredibly fast, arriving two days ahead of schedule. The packaging was secure with no signs of damage during transit. Quality appears robust; the machine feels solid and well-constructed with precise welding and a professional finish. Customer service was responsive, promptly answering my inquiries about delivery tracking. Overall, a very satisfactory purchasing experience from order to receipt.