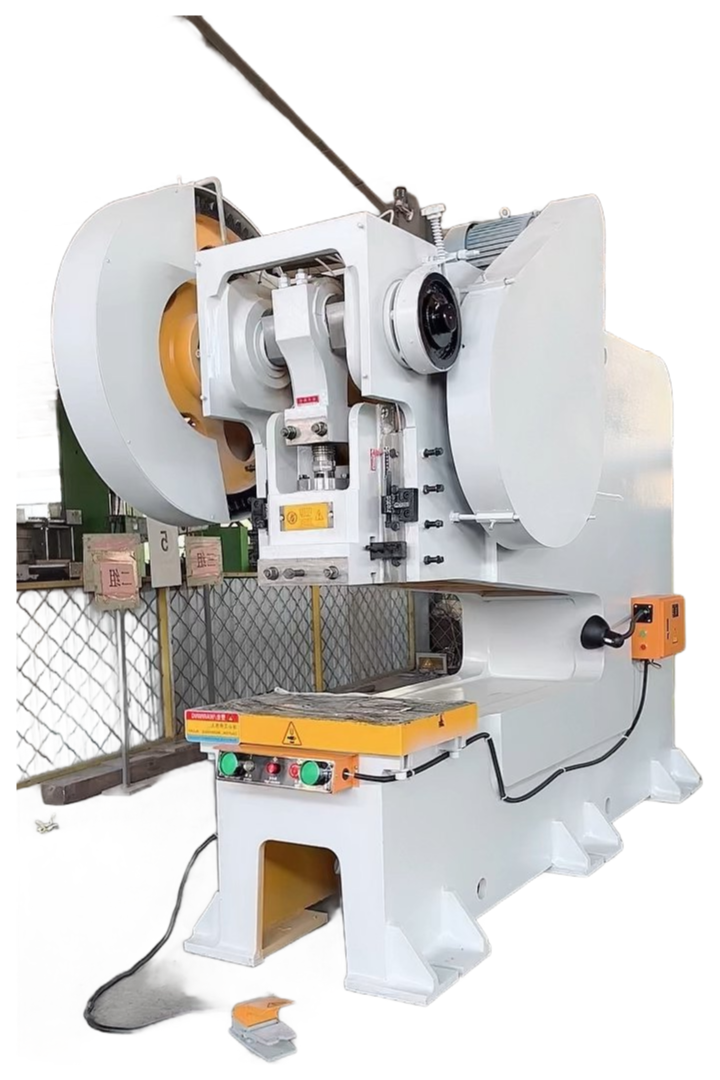

Our industrial stamping press machines are specifically designed for oil filter component manufacturing, including shell forming and end cap production. These heavy-duty machines ensure dimensional consistency and high-speed production for automotive filter applications.

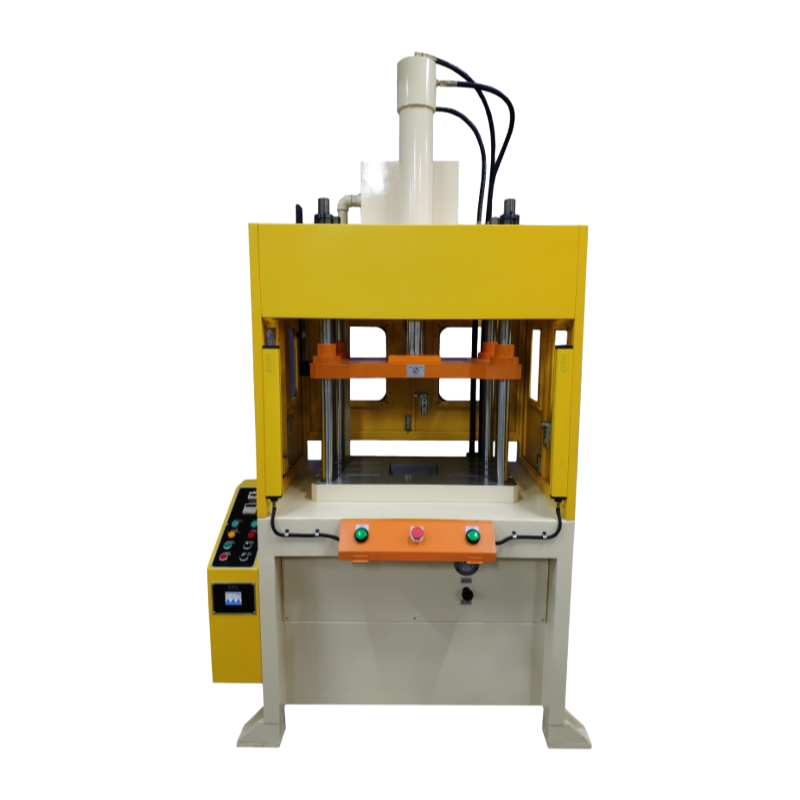

The hydraulic stretching machine enhances shell durability through controlled material deformation, creating compact structures with improved strength characteristics. This process is essential for producing reliable filter housings that meet automotive industry standards.

Key features of our stamping equipment include steel-welded frames, oil-bath lubricated gear systems, hydraulic overload protection, and precision height adjustment mechanisms. The machines incorporate international brand PLC controls and safety components for reliable operation.

The oil filter manufacturing process typically involves multiple stretching operations (3-6 passes depending on design complexity), intermediate edge trimming, and final assembly with filter media. Our equipment supports the complete production workflow from blank forming to final product testing.

A fantastic experience from start to finish. The delivery was incredibly fast and the logistics were handled with impressive efficiency. All components arrived securely packaged and on schedule, which was crucial for our production timeline. Regarding quality, the machine appears robust and well-constructed, meeting the high standards we expected from a factory-direct purchase. The initial service communication was prompt and professional, with clear answers to our pre-shipment inquiries. While we have not yet begun full operational use, the outward build quality and the smooth delivery process have given us great confidence in this investment. The overall process was seamless and stress-free.

Quick delivery and excellent packaging ensured the machine arrived safely without any delays. Quality-wise, the construction feels robust and durable, meeting industrial standards perfectly. Service was outstanding; the support team was responsive and helpful throughout the ordering process. Overall, a very satisfactory experience from start to finish.